What is automatic transmission? Any idea! In this article, we will explore automatic automation, along with types, advantages, disadvantages, etc.

Let’s explore!

What is Automatic Transmission?

Definition of Automatic Transmission

The automatic transmission systems are also known as the self-shifting transmission or dual pedal technology.

It is a multi-speed transmission system that doesn’t require input from the driver for changing gears under normal driving conditions.

- Automatic transmission systems are getting popular in modern cars due to its convenience of driving and easier driving.

- This system operates without clutch systems, it can automatically change gear ratios as per the vehicle moves and disables the need of manually shifting of gears.

Explanation

If you are not getting it, you definitely may have driven the scooty, mopeds. They don’t need to shift the gears manually they will automatically get adjusted as the vehicle propels.

- This kind of automatic transmission comes in handy in high traffic conditions.

- If you have a manual transmission vehicle it will be hard to move through traffic as the driver will have to change the gears continuously.

- Whereas, with automatic transmission, you just need to accelerate and adjust the speed.

History of Automatic Transmission

In the year of 1934 the semi-automatic transmission vehicle were released by the General Motors and REO. They had some improvements over the manual transmission but still there was a need of clutch to change the gears.

Later the General Motors used the hydraulically controlled planetary gearbox allowing the gears to shift depending upon the vehicle travel’s speed.

- From the development of hydraulic controlled gearbox, modern-day automatic transmission systems started to develop.

- From the year of 1960s, the two-speed and four-speed units started to disappear and are replaced with torque converters.

- Later with the electronics inclusion, the mechanical parts started to get replaced.

- Now, most systems use solenoids controlled by an engine control unit (ECU) or separate transmission control unit.

- The first six-speed transmission was debuted in 2002 year by BMW 7 series.

- Then the Toyota in 2007 released eight-speed transmission and nine-speed and ten-speed were used in 2013 by Toyota in Lexus LC.

There are different categories of automatic transmission systems. We will see each of them in short details.

Check out newly launched ‘MechStudies – The Learning App’ in Android device

and iOS device

for articles as well as various solved Mechanical Engineering Quiz/MCQs. The MCQs are fully solved with clear explanation.

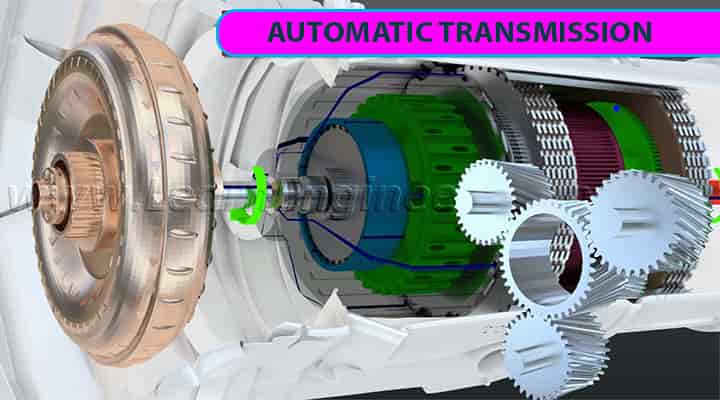

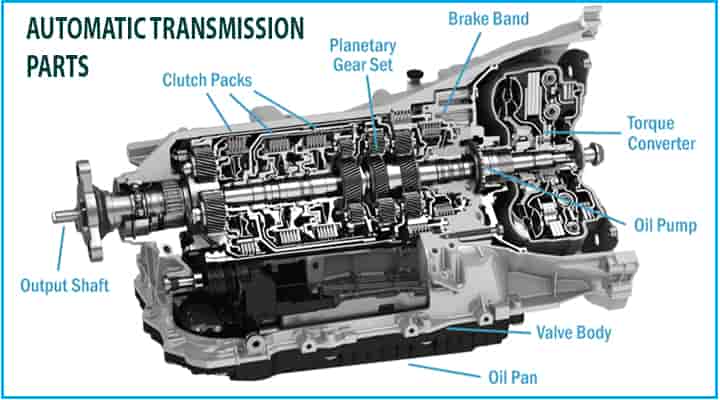

Parts of Automatic Transmission

This really a complex system and it has many parts by which the whole system works properly.

There are many parts in the automatic transmission.

The main parts are as follows,

- Transmission casing

- Torque converter

- Planetary gears

Transmission Casing

- Casing means where all parts are housed. Transmission casing means the casing where all automatic transmission parts are housed.

- It has sensors for controls.

- It is also known as bell casing.

- It protects all components.

Torque Converter

- In the manual car, we need to disconnect the engine power to the wheel. So, what about the automatic car? How the main shaft is disconnected from the engine power?

- This is because of the torque converter.

- It is mounted between engine power and transmission.

- It helps to transfer power from the engine to the transmission.

- It can increase or decreases the torque as well.

It has four main parts

- Pump or impeller

- Turbine

- Starter

- Clutches

Pump or impeller is directly connected to the flywheel and in case crankshaft rotates, impeller will also rotate. This impeller handled a working fluid.

Turbine is not directly connected to the impeller and it is indirectly connected to the impeller by the working fluid. So, as the turbine and impeller is not directly connected, both can run at different speed.

When impeller rotates, it sends working fluid to the turbine. This working fluid again come back to the impeller by a starter.

Torque converter clutch helps to engage and disengage between turbine power generation to the transmission.

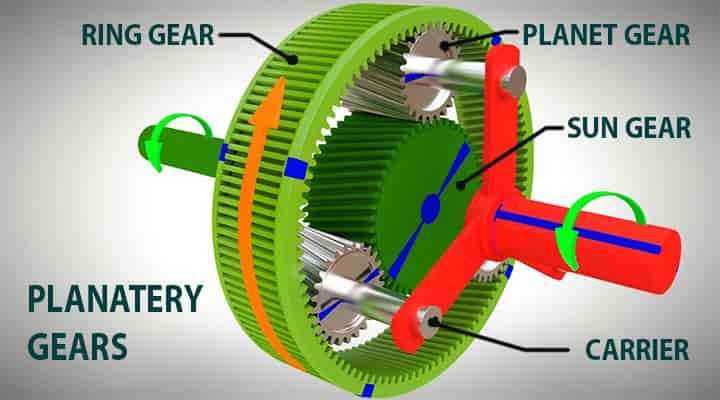

Planetary gears

As the name suggests, planetary gear means a combination of different kinds of gears like,

- Sun gear – it is placed at the center of the planetary gear and that is why it is known as the sun gear.

- Planet gears – Normally three planet gears and it is connected to the sun gear.

- Carrier – It carriers the planet gears.

- Ring gear – This is the outer gear and it has internal gear cutting.

XPH is your home for BMW, Audi, Ford Mustang, VW, Porsche and Nissan GTR aftermarket parts.

How does Automatic Transmission Works?

Let’s see the working principle of an automated transmission system in simple way!

Step#1

Start of the engine and power is produced.

Step#2

This power is transferred to the pump of the torque convertor.

Step#3

This power is further transferred to the turbine of torque converter with the help of transmission fluid.

Step#4

There is a stator which helps the transmission fluid back to the pump from the turbine.

- It multiplies the power of transmission fluid

- Because of the stator, pump provided more power to the turbine.

- Vortex power rotation is created.

Step#5

When the turbine rotates, the shaft where turbine mounted, also rotates. This shaft is connected to the planetary gear of the transmission system. Power is transmitted to the 1st set of planetary gears.

Step#6

Now, clutches are taking part to engage or disengage as well as provide different gear ratio in the transmission system.

Now, entire this process is explained with a simple animated video by LearnEngineering,

Types of Automatic Transmission

There are some common types of automatic transmission systems such as hydraulic automatic. But popularly known transmission systems are,

- continuously variable transmission systems (CVT),

- automated manual transmission (AMT), and

- dual-clutch transmission systems (DCT).

Let’s take a look at the history of automatic transmission.

Spring is here! Save big on our best-selling WAGNER TUNING BMW F CHASSIS N55 CATTED DOWNPIPE

Continuously Variable Transmission system (CVT)

What is a Continuously Variable Transmission System (CVT)?

The continuously variable transmission system (CVT) is the one which can change the gears in a continuous range seamlessly. Compared to the other transmission systems this one gives more range and flexibility. This characteristic of the continuously variable transmission allows the engine to run at constant RPM while vehicle is moving at varying speeds.

The CVT used pulleys or gears arrangements instead of those traditional steel gears. The continuously variable transmission system is mainly focused on fuel efficiency and continuous acceleration.

Type of CVT

So, there are some types of continuously variable transmission systems according to the use.

Pully based

The pully based CVT is the most common type of the continuously variable transmission systems. It uses a V-belt that runs between the two diameter varied pulleys.

- The pulleys consist of two cone-shaped halves that will move together and apart.

- So, the V-shaped cross-section will cause the belt to ride higher on one pulley and lower on the other.

- That’s how the gear ratio will be adjusted by moving the two sheaves of one pully close and the other two farther apart.

Toroidal based

The Toroidal based CVTs were used in the Nissan centric in 1999. It consists of the discs and rollers.

- There are two discs one of them acts as an input and other one is the output.

- Between these two discs, there are rollers that are responsible for varying the ratio and transfer power from one side to other.

Like example when the rollers axis will be perpendicular to the axis of disc the effective diameter will be same and it will give 1:1 drive ratio.

For getting other ratios rollers will be moved along the axis of discs. So, by moving the rollers the ratios can be changed.

Using toroidal CVT is advantageous because of the ability to withstand the high torque as compared to the pully-based.

Ratchet based

As the name suggests it has series of one way ratches. They have the ON and OFF characteristic so; this one is not in continuous operation that contradicts the CVT principle.

- The drive ratio can be adjusted by changing the linkage geometry.

- The Ratchet-based CVT can increase the torque throughput.

- The ratchet-based CVT drawback is vibration caused by the successive transition in the speed.

Hydrostatic

The hydrostatic-based continuously variable transmission uses a variable displacement pump and the hydraulic motor.

Hence, the transmission converts the hydraulic pressure generated into the rotation of the output shaft.

If we compare the hydrostatic CVTs to others, the hydrostatic ones are expensive than the others. There are some advantages of the hydrostatic like below.

- Torque capacity can be scaled

- Power transmission is done with flexible houses, it allows more flexible suspension system and simplifies the design.

- Precise vehicle movement and slow crawl speeds are achieved at full torque.

- It can be used to get or provide the speed of other hydraulic components used in the vehicle such as the hydraulic cylinder.

Cone

In case of the cone CVT the drive ratio can be varied by moving the wheel or belt up and down the axis of conical rollers.

- The simple version of the cone CVT is the single cone version.

- It uses a wheel that will move along the slope of the cone thereby creating variation between narrow and wide diameters of the cone.

- There is some design also that use two rollers.

Epicyclic

It is also known as the planetary CVT. The gear ration in this arrangement will be changed by tilting the axes of spheres in continuous way and providing different contact radii and turning drive input and out discs.

Infinitely variable transmission

Some CVT arrangements are able to get an infinite range of low gears. That is the reason why they are known as infinitely variable transmission systems.

In case, the output shaft speed equals to the difference between the other two speeds, infinitely low drive ratios are created in an epicyclic CVT.

Applications of CVT

- Starting from 1958 the continuously variable transmission system is used in the automobiles like DAF 600. In 1987 the Ford Fiesta was the first one to come up with the steel-belted CVT system.

- The recent cars with CVT are Toyota Corolla assisting with physical gear. Also, the CVT has a presence in hybrid electric vehicles like Nissan Altima.

- They are widely used in small vehicles like snowmobiles, motor scooters.

- In the farm and earthmoving equipment, the CVTs are used in the combine harvesters, small tractors, and self-propelled mowers.

- CVTs are also used in aircraft electrical power generating systems.

Dual Clutch Transmission System (DCT)

What is Dual Clutch Transmission System?

The dual clutch transmission is sometimes also known as the twin clutch transmission system.

- The dual-clutch transmission system is a combination of automatic and manual gearbox systems.

- The difference from an automatic transmission system is there is no torque converter like a traditional automatic transmission system.

Basically, there are two shafts with own clutch for gear shifting. One of them is equipped with even numbered gears and other one is odd numbered gears.

So, the DCT can pre-select an odd gear while the vehicle is moving forward with even gear. DCT’s can shift gears several times faster than the manual transmission system.

- Though the dual-clutch transmission system is the dry system.

- The system keeps the clutches and dry and wearing of the same may happen eventually.

- Also, the DCT can become noisy and rough for gear shifting.

Here are some applications in some cars of dual-clutch transmission systems.

Applications of DCT

- The DCT was introduced in 2003 in the Volkswagen Golf R32 using 6 speed DCT.

- It is used in the BMW M3, Ferrari California, Porsche 911, Kia Seltos and Hyundai venue and lot more.

- The DCT system were also used in the Mitsubishi Fuso truck.

- Apart from cars they are also used in the tractors such as Kirovets K-700 in Europe as well as in railcars.

Automated Manual Transmission System (AMT)

What is an Automated Manual Transmission System?

The automated manual transmission system (AMT) also known as the clutch-less manual transmission system.

This one is based on the mechanical design like the build of a conventional manual transmission but also uses automation to operate the clutch or gear shifting.

- These systems can be made fully automatic or semi-automatic in operation.

- The methods used for the automation can be pneumatic, hydraulic, electro-hydraulic, or electric motor.

- The gear shifting is made automated via electronic sensors, computers, and actuators.

The operation of the automated manual transmission system is when driver selects the desired gear with transmission shift lever.

While the sensors and actuators will be connected to ECU that will automatically operate the clutch to match the revs and re-engage wherever necessary. It is done in milliseconds of time.

The applications of the automatic manual transmission system are wide and still used in lots of cars.

Applications of AMT

- Most of the use of automated manual transmission systems is in passenger cars. It was first introduced and used in the 1940s – 1950s cars like Hudson Commodore in 1942.

- The introduction of electronics Renault in 1963 switched to fully automatic three-speed Jager transmission that had electro-mechanical control unit and was used for both clutching and shifting of gears.

- One of the popular manufacturers Ferrari used paddle shifters with a 6-speed transmission system with a fully automatic mode. It was the Ferrari F335. Later Alfa Romeo also introduced the Selespeed 5 speed automatic transmission.

- BMW started using the AMT system in 1993 with a 6-speed transmission system. The first model of BMW with AMT was the Alpina B12 Coupe.

- Other popular manufacturers Lamborghini used AMT on Murcielago E gear automated manual transmission system. The same was used on the Lamborghini Gallardo. Audi R8 also used the transmission and named it a R-tronic transmission system.

Now we have known all the types of automatic transmission systems.

Which one to Choose between CVT, DCT & AMT?

There all are types of automatic transmission, hence, is simple language these all are good. Now, if we have to choose, anyone of them, then what to choose?

Well, it’s a tricky question as it depends on the person to use and prospective of that person.

For example,

- If someone wants to speed up the car within a very small time, then DCT is the best choice within these three.

- If someone wants to have the best efficiency, CVT is the best choice.

- If anyone wants to have a cheaper automatic transmission system, then AMT is better.

Let’s see the differences between an automatic transmission and manual transmission.

Automatic Transmission Vs Manual

Let’s see the main difference between automatic transmission vs manual transmission for basic understanding.

| Automatic Transmission | Manual Transmission |

| In an automatic transmission, gear shifting is not required frequently | In a manual transmission, gear shifting is required frequently |

| Easy to drive | Difficult to drive |

| Very expensive | Less expensive comparative to automatic transmission |

| Manufacturer include this transmission in the higher models | It starts with car basic models. |

| Fuel efficiency is slight low comparative to manual transmission | Fuel efficiency is better than automatic transmission. |

| Maintenance cost is little high | Maintenance cost is low comparative to automatic transmission. |

| For high slope area, vehicles maintain in manual mode instead of automatic mode. | High slope area, manual transmission is preferable. |

Now let’s take a look at advantages and disadvantages of the automatic transmission systems.

Advantages of Automatic Transmission Systems

Easier to use

The main advantage of the automatic transmission systems is easier to use and convenience of drive. Though there is no rocket science learning to drive the manual transmission system car but still the practise is needed to drive. The automatic transmission systems takes pretty much less time for learning compared to the manual ones.

Better for hill areas

If you are not experienced driver you will definitely find it difficult to navigating through the steep inclines of hills. The automatic ones take care of these issues and operate efficiently.

Easier to use in high traffic conditions

The heavy traffic is one of the most irritating scenes especially for manual transmission vehicles. Because of need of changing the gears and operating clutch continuously. The automatic system is free from all of these issues and driver can easily control and navigate through the traffic.

Safety

The automatic transmission systems are kind of safer than the manual ones. Because of the easier way of driving and navigating easily through any conditions the automatic transmission systems are safer.

Disadvantages of Automatic Transmission Systems

Cost

The cost of automatic vehicles are more, basically the initial cost is higher as compared to the manual systems. The complexity increases with the automatic ones and they become costly.

Maintenance

As the automatic systems are more complex the maintenance required is also more than the manual transmission systems.

So, these are the advantages and disadvantages of the automatic transmissions systems. The inclusion of modern technologies is making automatic transmissions even better and the cost is expected to come down in coming time.

High Rated Automotive Engineering Course

Automotive 101: A Beginners Guide To Automotive Repair

Automotive Engineering: Automobile Fundamentals and Advanced

Automotive Engineering; Hybrid Electric Vehicles

Do it Yourself – Automotive Electrical Diagnosis – Beginner

Do it Yourself-Automotive Electrical Diagnosis-Intermediate

Automotive Engineering; Common Rail Direct Injection(CRDI)

Fundamentals of Internal Combustion Engines – IC Engines

Hybrid and Electric Vehicle for Beginners FULL Course 2021

Automobile Safety: Understanding Car Crashes for beginners

Hybrid Vehicles The Fundamentals & Operating Principles

Conclusion

Hence, we have got a basic idea about automatic transmission system along with different types, advantages, etc.

Any questions!

Check out newly launched ‘MechStudies – The Learning App’ in Android device

and iOS device

for articles as well as various solved Mechanical Engineering Quiz/MCQs. The MCQs are fully solved with clear explanation.

It’s great that you talked about how the main advantage of automatic transmission systems is easier to use and more convenient to drive. I just bought a secondhand car and I think its transmission needs to get serviced first. So, I need to ask for automatic transmission services this weekend.

https://www.perthgearbox.com.au/automatic-transmissions