In this article, we will learn the basics of pump priming along with the definition, meaning, types, requirements, etc. Let’s explore!

What is Pump Priming? Definition Meaning

Pump Priming Basics

Let’s start with the pump priming basics. Before understanding, it is essential to have a basic concept of the pump! Pumps are the devices that we used to lift fluid to achieve pressure energy. They are used in hydraulics systems on large scale.

Pumps are used to transfer fluids from one place to another and this process requires a lot of energy and this energy is imparted to the fluid by using pumps.

- There are basically 2 types of pump, positive displacement pump and roto-dynamic pumps.

- Roto dynamic pumps use centrifugal force to increase pressure of fluid.

- They increase energy level by combination of pressure energy, kinetic energy and centrifugal energy.

Centrifugal pump is a rotodynamic type of pump. But to operate this pump there are some precautions that have to be taken, one such precaution is priming of pump.

Pump Priming Definition & Meaning

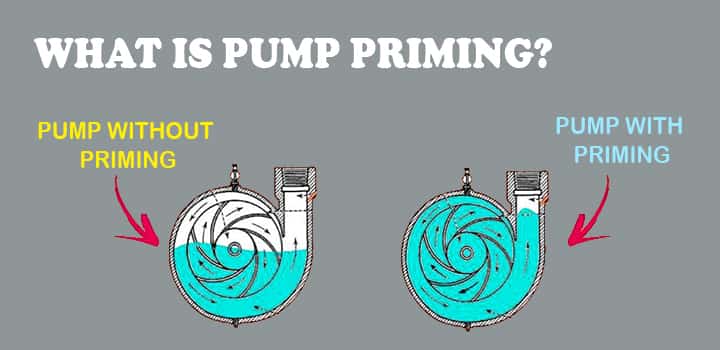

When the pump is started initially, its passageway, like the suction side and casing is filled with air or other gases. Pressure head generated by air is negligible compared to water and for some time water doesn’t get sucked inside of pump from the sump. Here, pump priming is introduced.

So, what does priming a pump mean?

The meaning of pump priming is simply to avoid this problem by removing the air or gases from the pump. Now, what is priming of pump? Let’s define

Hence, pump priming can be defined as a process of removal of air or other gases present in the pump to enable the centrifugal pump into the suction.

Why Priming of a Pump is Required?

So, we can summarize the main reasons for pump priming, as follows,

- Pump suction pipe and casing may have air or gas or it may have vapor, and the same needs to be removed by pump priming.

- These unwanted foreign particles, takes some volume and reduce the actual volume. Hence, pump priming helps to remove all these particles and maintain actual volume flow rate.

- It increases the efficiency of the pump.

- Without the priming, pump can run dry which may incur a mechanical damage to the pump.

- Pump priming reduces the overheating tendency of the pump internals.

- Pump priming reduces the maintenance as well as maintenance cost or operating cost.

Hence, we understand that pump priming is necessary for centrifugal pumps. As priming is necessary for centrifugal pumps, we need to understand the basics of centrifugal pumps.

Priming of Centrifugal Pump

Let’s get the basic idea of the centrifugal pump before the pump priming process.

Construction of Centrifugal Pump: It is made of a round casing generally it is made of strong cast iron or steel to withstand high pressure.

- This casing is airtight.

- It houses impeller.

- Impeller is a rotating disc which has buckets placed on it.

- Buckets are like grooves which guide fluid to move away from centre.

- Eye of impeller is a centre of impeller from which water gets sucked in to pump.

- Impeller is mounted on shaft which is connected or powered by prime mover.

- Pipe which is connected to eye of impeller is suction pipe while pipe connected to casing is called delivery pipe.

- Strainer is provided to suction pipe so as to remove impurities present in fluid.

- A foot valve is provided to the suction pipe so fluid moves in one direction only.

- A delivery valve is provided on the delivery pipe to stop flow further.

Working Process: Before starting pump priming is done, which means filling the casing of the pump with water. This is achieved by closing the delivery valve and allowing water to accumulate in the casing.

- When water is filled then pump is started and delivery valve is opened.

- When impeller starts to rotate at high speed, it throws water away from centre due to centrifugal force.

This centrifugal force is the reason high pressure gets developed at the periphery as compared to low pressure at the center.

- Water gets momentum due to speed of impeller and it gets dragged with it.

- As there was no air inside casing, as soon as impeller rotates, pressure near eye is low than outside pressure and hence water gets sucked in from sump.

- Casing of pump is narrow at start and it gets expanded till end where delivery pipe is connected.

- When impeller starts rotating, water moves away from centre due to centrifugal force and gains kinetic energy.

- Due to its high velocity as it moves ahead, area of casing increases and it gets expanded, this kinetic energy then gets converted into pressure energy and through delivery pipe this high pressure fluid gets delivered out.

These pumps are cheap and easy to operate. But they are not as efficient as the positive displacement pumps.

- As impeller never contacts casing, they have fairly long life, as less friction is there.

- No damage can be done to the pump by running dry.

- The biggest issue this pump has is cavitation.

- Cavitation is formation of bubble of air in pump and when these bubble explode they create knocking sound and pressure wave which affects pump health.

Another limitation is without priming these pumps don’t work.

How does Pump Priming Work?

Priming is simply the process of removing air present inside the casing and suction line of the centrifugal pump. During this process, water is filled in the casing with displacing air from it. To understand with an easy example.

Pump Priming Working Principle

Imagine you are holding a rope and at its extreme end, a bucket is attached. When you start rotating this bucket then it will also rotate as it is light in weight and is filled with air.

- Tension gets developed on the rope when you are rotating this bucket. Consider T1.

- Now imagine same bucket when filled by water and if rotated then it will be heavy and tension developed in this case T2 on rope will be very high as compared to T1.

This tension gets developed by force acting outside known as centrifugal force.

How Does the Air Remove?

Now we know the density of air is 1.22 kg/m3. Whilst density of water is 1000 kg/m3. To calculate pressure,

- P= ρ g h

- P air = 1.22 x 9.81 x h = 9.8 h

- P water = 1000 x 9.81 x h = 9800 h

So as you can see pressure developed when water was in the bucket is 1000 times that of air in the bucket. Hence pressure head generated by water is very high and the pressure head generated by air is very low and hence water does not get sucked initially.

The density of air is very low as compared to water due to this reason, suction is not possible from the sump. And hence this air has to be removed from passageways.

In case of centrifugal pump, suction depends on delivery/discharge of the pump. This is low pressure getting developed at the center of an impeller is due to high pressure created by centrifugal force at the periphery. If discharge gets reduced this automatically impacts suction pressure.

Types of Priming of Pump

There are various methods of priming of pump, let’s see all of them for basic understanding!

- Manual priming

- Natural Priming

- Priming by vacuum pump

- Priming by jet pump

- Priming by separator

- Priming by Foot Valve

- Priming by Ejector

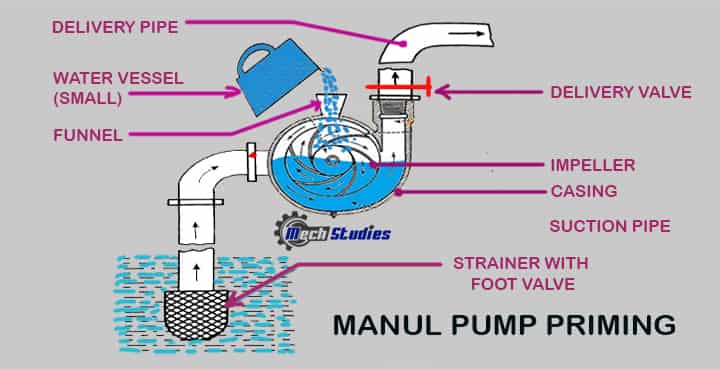

Manual Pump Priming

In this process, a funnel is provided on the delivery side but it is provided below the delivery valve. The delivery valve is closed and the pump is filled with water by pouring through the priming funnel.

- Casing and suction pump gets filled with water.

- So as soon as water is filled, air which was present in casing is simultaneously removed from air vent valve.

- Air vent valve is provided on casing to remove this air.

- When whole casing is filled with water, water will come out of this valve which will prove priming is completed.

- After which air relief valve is closed and pump is started after opening delivery valve.

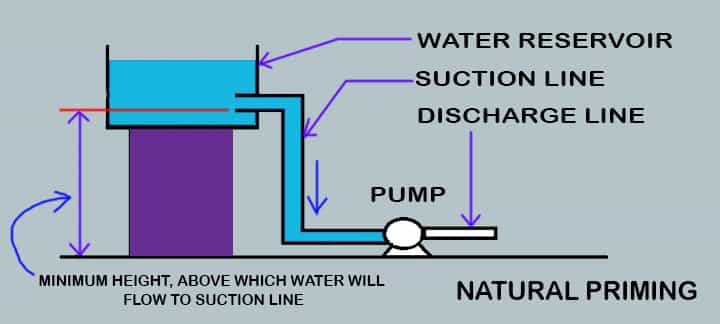

Natural Pump Priming

As the name suggests, natural pump priming means the priming process will be happening naturally. So, how is it possible?

- Water enters in the centrifugal pump through the impeller eye. Hence, if the suction side of water surface if little higher than the impeller eye, the water will automatically enters into the pump.

- In this case, no additional efforst are required for priming and the process will be happening naturally.

- Simple liquid property helps to flow.

- Air or gases are removed naturally.

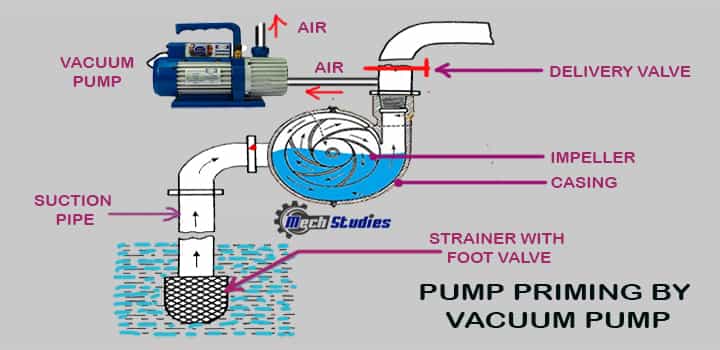

Priming by Vacuum Pump

As the name suggests small size vacuum pump is connected to the delivery side of the pump.

- This pump is connected just below the delivery valve.

- This valve is closed. Suction line of this vacuum pump is joined to delivery side of centrifugal pump.

- Generally, reciprocating pumps are used.

- On being switched on this vacuum pump sucks air from casing of centrifugal pump, suction side as well as delivery side.

- As soon as air is removed, vacuum gets created as pressure inside centrifugal pump falls below atmospheric pressure and hence water from sump gets sucked in pump and pump casing gets filled.

- As soon as this is done centrifugal can be operated to achieve desired results and vacuum pump is switched off.

- Vacuum pump have lot of moving parts so their maintenance issue sometimes affect centrifugal pumps operation.

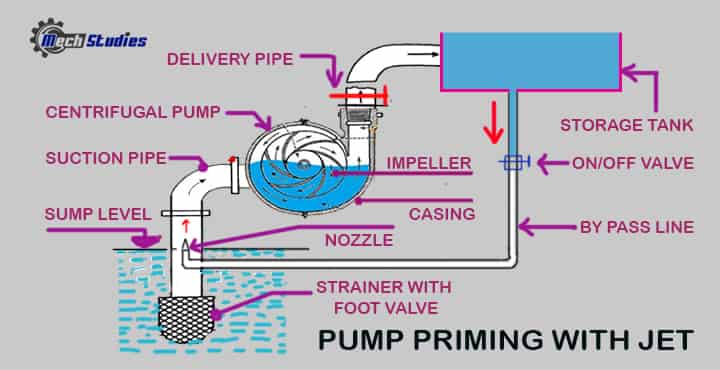

Priming with jet pump

In this method, a high head of water stored in a tank is used to do priming. A bypass line is passed from this delivery tank is brought inside the suction side of the centrifugal pump.

- A specific type of nozzle is fitted at its end.

- One valve is provided to switch on or off supply of water from tank.

- Before starting the centrifugal pump, this valve is to be opened.

- This will result in water passing through this bypass line to the nozzle.

- This nozzle is specifically designed such that this pressure is less than atmospheric pressure, so it causes suction of water from sump.

- This water from low pressure travels to casing and water gets filled.

- Then valve is switched off to operate centrifugal pump.

Priming with Separator

For applying this method some design changes have to be made in the design of the centrifugal pump.

- First change is that air separator is fixed at delivery side of centrifugal pump.

- To air separator delivery pipe is connected.

- Air separator is a device which separated air from water droplets.

- This is achieved by gravity and density variation between fluids.

- Second change is to be done in suction side.

- Here suction pipe connecting to eye of impeller must have large bend shape. Preferably S Shape.

- This shape is preferred because this inlet pipe due to its shape will always hold some water, which is remaining there from last operation. This water gets used to remove air from casing.

- When centrifugal pump is switched on this water gets sucked into eye of impeller.

As the casing is filled with air and water both, both get rotated and due to centrifugal force, forced out into the air separator.

As air has low density and water has high density, air will go up while water will fall down and it is also due to gravity.

So this same water keeps pushed out and falls down and this repeating process air gets slowly removed from casing. Sometimes vent is also provided to air separator, that way it removal of air can be noticed. As soon as the air gets removed, centrifugal pump starts its normal functioning.

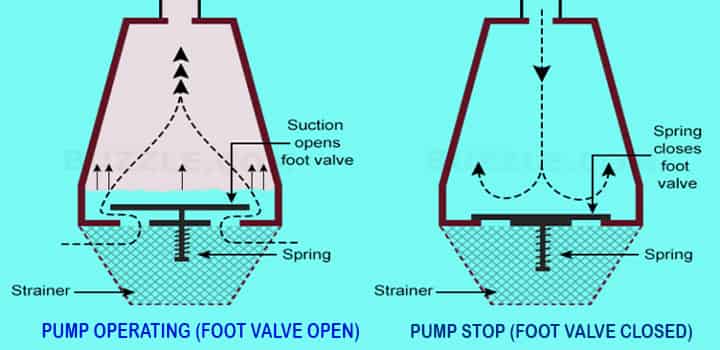

Priming by Foot Valve

Pump priming by foot valve is not for the initial priming process. However, once the pump is started after the priming by any other methods, the foot valve will assure that in the next restart, pump priming will be done by it.

- Foot valve acts as non return valve, it means it allows liquid only one direction. (from sump to pump).

- Opposite direction, foot valve stops the liquid to flow.

- After pump restart second time or later, liquid will be available inside the pump casing as well in the suction side.

- Foot valve doesn’t allow this liquid to exit.

- So, pump will be filled with water and there will not be any space to enter air or other gases inside the pump.

- Hence, foot valve acts as a device for pump priming.

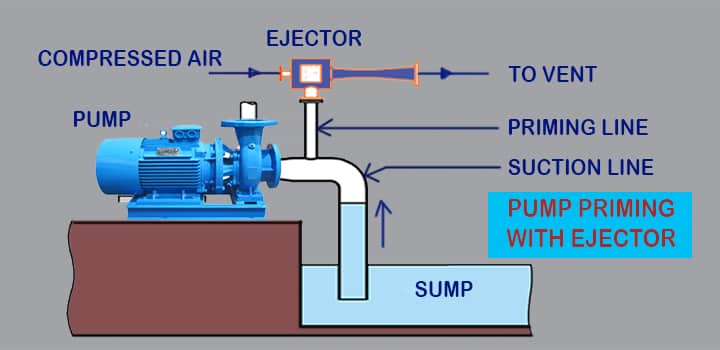

Priming by Ejector

We all know that ejectors are used to create vacuums in many industries and the same is applied for pump priming as well. Let’s see how does it work?

are used to create vacuums in many industries and the same is applied for pump priming as well. Let’s see how does it work?

- Ejectors are installed at the suction side of a centrifugal pump.

- It creates vacuum at the suction side.

- Due to the vacuum inside the suction pipe, adjacent liquid from the sump tends to filled up that vacuum.

- Liquid flow starts from the sump to the suction pipe as well into the pump.

When Pump Priming is Not Required?

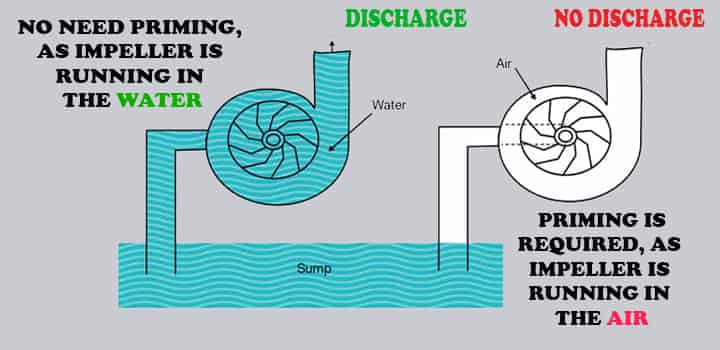

We have understood the requirements of priming of the pump and when to use it. But do you know there are few cases where priming is not required? Let’s see!

- If the pump is having its dedicated priming system, that is self priming pump.

- If the pump is submerged into the water.

- If the pump impeller eye is below the water surface at suction.

- If the pump is having flooded suction.

Here, we understand the primary concept of the priming of the pump. We have already learned about the types of pumps. However, do you know that pump is also classified by Pump Priming?

Yes, it is! Pumps are further divided into two types based on priming.

- Self-priming pump

- Non self- Priming pumps

Pumps that are to be filled by water manually, are called a non-self-priming pump and the pump which is not required to fill water in every starting is known as self priming pump.

Let’s learn about the selection of liquid for priming process!

Selection of Liquid for Pump Priming

Priming is done by the same liquid which is to be pumped by a pump. If oil is being pumped by a pump then water cannot be used, as it will cause emulsification of oil. It will also lead to different chemical reactions which will affect the pump. So if it is an oil pump then priming is to be done by oil only.

There are some solutions where water can be used for priming. If the solution is of ammonia, water can be used. Urea solution is there, there to water can be used. The point is as long as the solution is made of a majorly part of water then water can be used.

Acid and water are not mixed, so such chemical reactions are exothermic, then water cannot be used for priming.

Difference Between Pump Priming and cavitation

Many times, there is confusion between pump cavitation and pump priming. However, please don’t be confused as these terms are different.

Let’s see the basic differences to clear our concept.

| Description | Pump priming | Pump Cavitation |

| Basic | It is the process of filling liquid into the suction side, pump casing, up to the delivery valve. | It is the effects of the bubble formation at the suction side that carries further to the pump inside and burst, causes damage to the impeller as well as the pump. |

| Saturation Pressure | It is not related to the saturation pressure | It is related to the saturation pressure |

| Air/gas removal | Air or gas needs to be removed by this process. | It is the effect of pump suction pressure below the vapor pressure |

| Effects | It helps to start the pump by removing air or gases from the pump. | It produces noise, vibration as well as damage pump internal parts. |

| When to do | Priming shall be done before the pump start. | Cavitation is a phenomenon, and to avert this, manufacturers are designed the pump during manufacturing. |

| Visibility | It can be understood as without proper priming, the pump will not work | It can be seen when the pump inside or impeller can be inspected. |

Applications of Priming

- Agriculture and irrigation – preferred because of robust design and high mass flow rate.

- Fire fighting equipment – due to high discharge.

- Steam and diesel power plant

- Hydraulic control system

- Water pumping stations

- Petroleum industry

- Chemical industry

- Food processing industry

Installation Tips for Priming Pumps

- Limit the vertical limit for suction side, proper calculation of NPSH are must to avoid issues created by vapour pressure.

- Suction pipe diameter should match properly with pump. Suction piping and static lift should be minimum to reduce priming time. Excesses priming time causes vaporisation of water in casing.

- Piping connections should be airtight to avoid cavitation. Flange and joint fittings should be minimum.

- Discharge pipe design should be such that it should send some water down in the influence of gravity when pump is switched.

- Foot valve is not used in self-priming pumps.

Conclusion

Hence, we have learned the basics of pump-priming, definition, types, requirements, etc.

I’ve recently started a blog, the information you provide on this web site has helped me tremendously. Thanks for all of your time & work.