In the heart of modern automation lies a component pivotal to precision and efficiency: the servo drive. A cornerstone of advanced machinery, servo drives facilitate the nuanced control of motor operation, ensuring movements are both precise and smooth. This introduction peels back the layers on servo technology, spotlighting its significance in the automation landscape.

How Do Servo Drives Enhance Industrial Performance?

Before delving into the intricacies of servo drive operation, it’s essential to understand the breadth of benefits they bring to the industrial table. Servo drives are not just about precision; they redefine efficiency, speed, and adaptability in industrial operations. Here’s a glimpse into their transformative impact:

- Precision and Accuracy: Enhancing product quality with exact movements.

- Speed and Efficiency: Accelerating production lines while conserving energy.

- Flexibility: Adapting to varied tasks with simple reprogramming.

- Reduced Wear and Tear: Prolonging machinery life through smoother operations.

Which Industries Benefit the Most from Servo Drives?

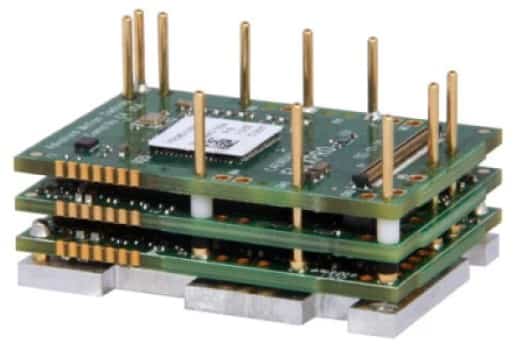

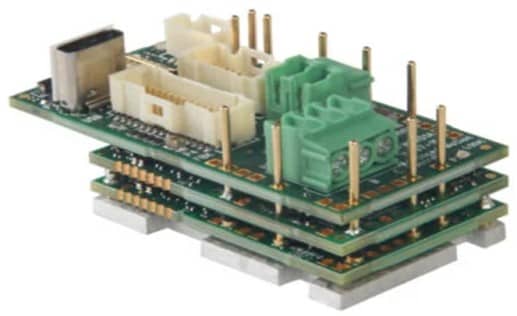

Advanced Motion Controls is a leading servo drive and controller manufacturer specializing in producing and offering a range of products designed for various applications across industries such as manufacturing, robotics, aerospace, and more.

is a leading servo drive and controller manufacturer specializing in producing and offering a range of products designed for various applications across industries such as manufacturing, robotics, aerospace, and more.

The versatility of servo drives sees them championing performance across a broad spectrum of sectors. Each industry harnesses these benefits to cater to specific challenges and operational demands.

Robotics and Automation

Robotics and automation represent the essence of servo drive application. Here, servo drives empower robots with the ability to perform complex tasks with human-like dexterity and speed.

- Industrial Robots: Facilitating precise assembly, welding, and painting.

- Automated Guided Vehicles (AGVs): Enhancing navigation and load handling.

- Drone Technology: Improving stability and control in flight operations.

Packaging Industry

In packaging, speed and reliability are paramount. Servo drives answer this call, ensuring machinery can adapt to different packaging sizes and materials with unerring accuracy.

- Filling Machines: Guaranteeing precise volume control.

- Labelling Equipment: Ensuring accurate label placement.

- Sorting Systems: Enhancing speed and reliability in product sorting.

Manufacturing Industry

At the forefront of servo drive application, the manufacturing sector utilizes these systems to bolster both speed and precision. Applications range from assembly line robots to CNC machines, each benefitting from the nuanced control servo drives offer.

- CNC Machining

: Elevating precision in cutting and shaping materials.

: Elevating precision in cutting and shaping materials. - Robotics: Empowering automated assembly with dexterous movement.

- Injection Molding: Optimizing cycle times and product quality.

Printing and Textile Machinery

The demand for quality and precision in printing and textiles finds a solution in servo drive technology. From high-speed presses to fabric cutting, servo drives ensure exceptional outcomes.

- Digital Printing Presses: Achieving high-speed, high-quality prints.

- Textile Cutting Machines: Ensuring precise fabric cuts for uniformity.

Medical and Healthcare Equipment

In the realm of medical and healthcare, servo drives contribute to life-saving precision in devices and diagnostics.

- Surgical Robots: Enhancing precision in minimally invasive surgery.

- Diagnostic Machines: Ensuring accuracy in imaging and analysis.

Aerospace and Defense

Servo drives elevate the capabilities of aerospace and defense equipment, where precision and reliability can mean the difference between success and failure.

- Satellite Positioning: Ensuring precise orientation in space.

- Unmanned Aerial Vehicles

(UAVs): Providing stability and control in varied conditions.

(UAVs): Providing stability and control in varied conditions.

Entertainment and Stage Engineering

Even the world of entertainment benefits from servo drive technology, which it brings dynamic movements to the stage and screen.

- Automated Stage Sets: Creating seamless scene transitions.

- Animatronics: Bringing lifelike movement to characters and effects.

How Do Servo Drives Work?

Understanding servo drives begins with their basic operation and components. At their core, servo drives modulate power to the motor, dictating speed, position, and torque with unparalleled precision.

Key Components of Servo Drives

The anatomy of a servo drive system reveals a harmonious interplay of components, each critical to its operation:

- Encoder: Feeding back precise position information.

- Controller: Dictating the motion based on input commands.

- Power Amplifier: Modulating the motor’s power supply.

The Process of Controlling Motion with Servo Drives

The magic of servo drives unfolds in their ability to control motion. This process, broken down into steps, showcases their role in facilitating precise and adaptable movements:

- Command Input: Defining the desired motion.

- Position Feedback: Ensuring accuracy through real-time updates.

- Adjustment and Control: Modulating power to achieve the commanded position.

What Are the Technical Advantages of Servo Drives?

Delving deeper into the technical prowess of servo drives unveils a suite of benefits that underscore their industrial indispensability:

- Dynamic Response: Reacting swiftly to command changes.

- High Torque at Low Speeds: Maintaining power where it’s most needed.

- Energy Efficiency: Reducing consumption through precise control.

Choosing the Right Servo Drive for Your Industry

The journey towards integrating servo drive technology begins with selecting the right system. This process hinges on understanding both the demands of the application and the capabilities of different servo drives.

Factors to Consider When Selecting Servo Drives

Navigating the array of servo drives on the market requires a discerning eye for critical factors:

- Power and Torque Requirements: Matching the drive to the load.

- Environmental Conditions: Ensuring suitability for the operating environment.

- Control Precision: Selecting drives that meet the application’s accuracy needs.

Understanding Servo Drive Specifications

Deciphering servo drive specifications is a crucial step in aligning technology with industrial needs. Key specifications include power output, torque range, and control resolution, each playing a pivotal role in ensuring the selected drive meets the application’s demands.

specifications is a crucial step in aligning technology with industrial needs. Key specifications include power output, torque range, and control resolution, each playing a pivotal role in ensuring the selected drive meets the application’s demands.

Implementing Servo Drives in Your Operations

The adoption of servo drive technology is a calculated process, from initial selection to final integration.

Installation and Setup

The introduction of servo drives into industrial systems follows a structured approach, ensuring compatibility and optimal performance:

- System Integration: Aligning the servo drive with existing machinery.

- Programming and Calibration: Customizing operations to meet specific requirements.

Maintenance and Troubleshooting

Maintaining servo drives is essential for their longevity and reliability. Regular checks and troubleshooting can pre-empt issues, ensuring continuous operation.

Future Trends in Servo Drive Technology

Looking ahead, servo drive technology stands on the cusp of further innovation. Emerging trends point to smarter, more interconnected systems, capable of even greater precision and efficiency.

Case Studies: Success Stories of Servo Drive Implementation

Illustrating the transformative impact of servo drives, case studies across industries highlight their role in enhancing operational efficiency, product quality, and innovation.

Frequently Asked Questions about Servo Drives

A dedicated section addresses common inquiries, shedding light on the nuances of servo drive technology and its application across industries.

Conclusion

The journey through the world of servo drives uncovers their indispensable role in modern industry. From enhancing precision and efficiency to fostering innovation, servo drives stand as a testament to the transformative potential of automation technology. As industries evolve, the continued integration of servo drives promises not only to meet the demands of today but to pioneer the advancements of tomorrow.