The annealing process along with the basic concept, purpose, meaning, definition, different types of annealing, advantages, disadvantages, applications are well captured. Let’s explore the Annealing process!

What is Annealing Process? Definition & Meaning

Let’s try to understand the basics of annealing process, definition, meaning & temperature.

What Does Annealing Process Mean?

Everything we use today like, utensils, appliances, or any other parts comes after some processes. There are some popular treatments done on the materials one of them is the heat treatment.

- The annealing process is one of the popular heat-treatment processes.

- So, basically, annealing is the process in which the physical or sometimes chemical parameters of the material are altered.

- Also, there are some types of annealing processes in which different methods of annealing are used.

This is done for lots of things, like,

- improving the ductility,

- reducing the hardness,

- improving workability, etc.

Annealing Meaning & Temperature

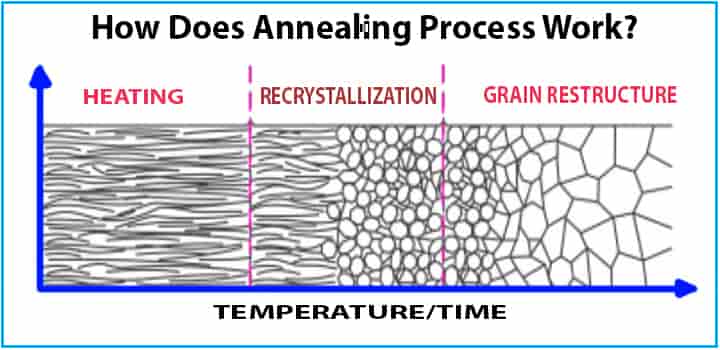

In the annealing process, the material is heated above its recrystallization temperature.

- If you don’t know what’s recrystallization temperature is, here is a simple definition.

- If you heat the material above a certain temperature, it’s different for every material.

- Now, at the recrystallization temperature, the deformed grains will be replaced by the new grains.

- That’s how the material properties can be changed accordingly.

In annealing, the material will be heated to the recrystallization temperature and thus the next methods will be applied for the change of properties in the materials. The process is easy to understand and simple.

Annealing Definition

So, the general definition of annealing is to heat a material to an appropriate temperature for a certain period, and then cooling it down slowly is called annealing. But why we need to do the annealing process? Let’s see it for the purpose of annealing next.

What is the Purpose of Annealing Process?

The purpose of the annealing process is followed,

- Annealing is used mostly to reduce the hardness of the steel, improve the plasticity and facilitation of the machining and cold deformation processing.

- For changing the chemical composition and organization of uniform steel, grain refinement, improving the performance of steel, and preparing it for the quenching process.

- Elimination of the internal stresses.

- Process hardening and to prevent deformation and cracking.

- Improve formability, recrystallize cold-worked metals

- Decrease electrical resistance and improving the magnetic properties

- Increase toughness

In the case of ferrous metals, such as steel, annealing is performed by heating the material (generally until glowing) for a while and then slowly letting it cool to room temperature in still air. Copper, silver, and brass can be either cooled slowly in the air or quickly by quenching in water. In this fashion, the metal is softened and prepared for further work such as shaping, stamping, or forming.

How Does Annealing Process Work?

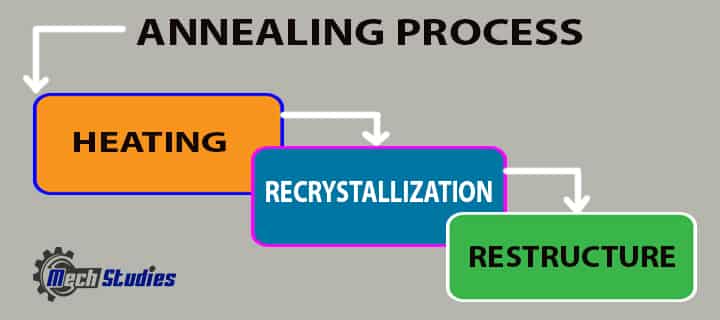

From the definition of annealing, we have already understood that this process means,

- Heating at specific temperature, that is heating

- Keep it for certain time, this time recrystallization happens

- Cooling it slowly, this time grains will be restructured.

For simple understanding, take some vegetables and cook at certain temperature and after cooking you have to allow your tasty vegetables in the over itself. This is the same as annealing process. The metal undergoes this process to make it a little softer so that metals can be machined easily. We can categorize this process into three steps,

- Heating

- Recrystallization

- Restructure

Annealing Process Step#1: Heating

- In this step, metal is heated with a furnace or oven at a specific temperature.

- Internal structure or molecules are loosed enough and relax due to the heating.

Annealing Process Step#2: Recrystallization

- In this stage, recrystallization happens.

- Due to heating at this temperature and even more temperature, deformed grains replace with new grains.

- Internal structure of metal is changed.

Annealing Process Step#3: Restructure

- In this stage, new grains are fully developed after recrystallization.

- Slowly cooling helps to restructure the metals and earn the ductility.

So, there are seven types of the annealing. In includes different methods and heating at some different temperatures. Let’s check out some of the types and details of the annealing processes.

Types of Annealing Processes

There are different types of annealing process, like

- Complete annealing process

- Process annealing

- Stress relief annealing

- Spheroidizing annealing

- Isothermal annealing

- Diffusion annealing

- Incomplete annealing

Let’s learn all the process one by one,

Complete Annealing Process

What is Complete Annealing?

The complete annealing process is generally used for getting improvement in the ductility of the material .

.

- So, in this process, the steel will be heated to about 50 degrees Celsius to 60 degrees Celsius above its critical temperature.

- The steel will be maintained at this temperature for a certain period of time.

- After that, the material is allowed to cool, the rate of cooling can be about 10 degrees Celsius per hour.

The steel will be cooled in the furnace slowly without any forced cooling operations. The complete annealing process is generally used for the sub-eutectic steel that has 0.3 to 0.6 percent of carbon content. We can refer like,

- medium carbon steel,

- low carbon steels,

- alloy steel castings,

- forged and hot-rolled profiles, and

- sometimes in the welding of these materials.

After the complete annealing process the properties like strength, hardness, toughness. What’s the objective or aim of this process? Let’s know it now.

Objectives of the complete annealing

- The fine grain structure, uniform structure, internal stresses elimination is done after this process.

- It will also reduce hardness, improve machining of the steels.

- Increased ductility, removal of internal stresses.

- For producing equilibrium microstructure.

Process Annealing Process

What is Process Annealing?

The process annealing is used for the low carbon steel.

- In this process, the material is heated and to temperature, just below the lower critical temperature of the steel or above its recrystallization temperature of steel, and

- after that, it will be allowed to cool slowly for some period of time.

Cold worked steel will have increased hardness and a decrease in the ductility. Thus, it will difficult to work. Process annealing will improve the ductility and decrease the hardness. This is generally carried out on cold-rolled steel like wire-drawn steel etc.

Objectives of process annealing

- The process annealing is done for the recrystallization of the metal.

- During the process of process annealing the new equiaxed, strain-free grains nucleate at high-stress regions in the cold worked microstructure. The hardness and strength of the metal will decrease whereas the ductility of the metal will increase.

- Basically, the main aim of the process annealing is to restore the ductility of cold worked metal.

Stress Relief Annealing

What is Relief Annealing?

In the stress relief annealing, the metal will be heated to a lower temperature of about 650 degree Celsius and will be kept at the temperature for them sometime in the furnace, and the internal stress of metal will be removed followed by the slow rate of cooling.

- As the name suggests the process removes the internal stresses of the materials.

- Like, larger castings or welded structures have internal stresses due to the manufacturing process and uneven cooling.

- There is no phase transformation of the phase that take place during the stress relief annealing

Objectives of stress relief annealing

The main of stress relief annealing is to remove the internal stresses. These internal stresses are created due to,

- Plastic deformation

- Non-uniform cooling

- Phase transformation

Spheroidizing Annealing

What is Spheroidizing Annealing?

The spheroidized annealing is for the materials like high carbon steel and alloy steel.

- This process improves the machinability of these materials.

- In spheroidized annealing process, the steel is heated to the temperature below its A1 temperature (Phase Diagram) and will be kept at the temperature for sometimes then allowed for slow cooling.

- The temperature holding time varies from 15-25 hours.

The spheroidized annealing improves the internal structure of the steel.

- In this process, the material is heated just below the critical temperature of the steel and the temperature is maintained generally around 700 degree Celsius and allowed to cool down.

- The heating and cooling of the material are done alternatively like above and below the critical temperature.

Objectives of spheroidized annealing

- The main objective of spheroidized annealing is to improvement of the machinability of the steel.

- The process reduces the hardness, uniform structure and prepare the steel for further process of quenching.

- If we talk according to the iron-carbon equilibrium diagram the cementite will be converted to the spherical form.

Isothermal Annealing

What is Isothermal Annealing Process?

The isothermal annealing is done for the low carbon steels and alloy for improvement of their machinability.

- In this process the steel will be heated above the upper critical temperature thus it will convert to austenitic steel pretty much rapidly.

- After the heating, it will be cooled to the temperature below the lower critical temperature about 600-700 degree Celsius.

- The cooling in this process is done by using the forced cooling methods.

The temperature will be maintained at this point for specific period of time for producing the homogenous structure in the material. Let’s check out some objectives of the same process.

Objectives of Isothermal annealing

- The process is suitable for the steels like high carbon steel, alloy tool steel, high alloy steel etc.

- Isothermal annealing is good for achieving the uniform organization and performance.

Though the isothermal annealing is not suitable for the large section steel parts and large batch furnace materials Why? Because in isothermal annealing it is not easy to achieve the isothermal temperature for the internal or batch workpiece.

Diffusion Annealing

What is Diffusion Annealing?

The process of diffusion is suitable for the high-quality steel and segregation of serious alloy steel casting and ingots.

- In the diffusion annealing, the iron and carbide will diffuse with each other.

- For the diffusion process, a higher temperature is required and the steel has to be heated above the upper critical temperature.

The temperature is high as like 1000 to 2000 degree Celsius and the heat preservation time is about 10 to 15 hours. After the process of diffusion annealing the complete annealing or normalizing has to be done to refine the tissue.

Objectives of Diffusion annealing

- The diffusion process eliminates the dendritic segregation and regional segregation.

- It also homogenizes the composition and organization.

Incomplete Annealing

In the incomplete annealing, the steel is heated about to its upper critical temperature. Later it is cooled at a slow rate after thermal insulation. The process is mainly used for obtaining the spherical pearlite tissues for hyper eutectic steel to,

- eliminate the internal stress,

- reduce the hardness and

- improve the machinability.

Now we have known the types of annealing process. There is one more process known as the normalizing. There is difference between these two process annealing and normalizing. We will get to know it now.

Difference Between Annealing and Normalizing

| Sr No. | Annealing Process | Normalizing Process |

| 1 | Annealing is the heat treatment process used for making the metal ductile and reducing hardness. | Normalizing is the heat treatment process applicable to alloys of iron. |

| 2 | The steel is either cooled in air or quenched in water. | The steel is cooled only in air. |

| 3 | In annealing, the uniform grain size is not easy to attain. | In normalizing, its easy to attain the uniform grain size. |

| 4 | Grain size distribution is more. | Grain size distribution is less. |

| 5 | The annealing takes more time | The normalizing takes less time. |

| 6 | The annealing cost is more compared to normalizing. | The cost of normalizing is less compared to annealing. |

| 7 | The structure of the grain is coarse. | The structure of the grain is fine. |

Now let’s checkout some of the advantages and disadvantages of annealing and its applications.

Advantages of Annealing

The advantages of this process are as follows,

- Annealing improves the ductility of the material reducing the hardness.

- Annealing is one of the best processes for improving machinability.

- It also helps the improvement of the magnetic properties of the material.

- Annealing also reduces the brittleness of the material.

- Elimination of the internal stresses can be done via annealing.

Disadvantages of Annealing

There are a few disadvantages as well,

- The electrical resistance of the material decreases using annealing.

- The cost of the annealing is more compared to the normalizing process.

- Coarse grain structure is available in the annealing.

- Unform grain size is not achieved in the annealing process.

- The annealing process takes time.

Applications of Annealing

The applications of the annealing are as follows,

- Removal of internal stresses of the materials.

- For improving the ductility of steel and reducing the hardness.

- Reduction of the brittleness of materials.

- For making the material more workable.

- Gears are manufactured using annealing.

Conclusion

So, that’s all for the annealing process. Annealing is only one of the heat treatment processes and there are many other heat treatment processes also available.

This post post made me think. I will write something about this on my blog. m

There is noticeably a bundle to learn about this. I assume you have made specific nice points in features also.

Your home is valueble for me. Thanks!? This web site is known as a walk-via for all the information you needed about this and didn know who to ask. Glimpse right here, and also you l definitely uncover it.

I found your article very thought provoking. The way it was written made me look at things from a different angle and think about what I originaly thought, why not visit us .I will definately be back again.

It’s seldom that I feel compelled to comment on articles, but you’re material is content-worthy. Thank you for being so conscientious about what you write.

I will invite all my friends to your blog, you really got a great blog.`*’;:

great submit, very informative. I wonder why the other experts of this sector don’t notice this. You must proceed your writing. I’m sure, you’ve a great readers’ base already!|

These are truly wonderful ideas in about blogging. You have touched some good factors here. Any way keep up wrinting.|

I could not resist commenting. Exceptionally well written!|

What’s up i am kavin, its my first occasion to commenting anyplace, when i read this article i thought i could also make comment due to this brilliant article.|

Very nice post. I just stumbled upon your blog and wanted to say that I’ve truly enjoyed surfing around your blog posts. After all I will be subscribing to your feed and I hope you write again very soon!|

Great post. I was checking constantly this blog and I’m impressed! Extremely useful info specially the remaining section 🙂 I deal with such info a lot. I was looking for this particular information for a long time. Thanks and good luck. |

Pretty nice post. I just stumbled upon your blog and wanted to say that I’ve really enjoyed surfing around your blog posts. After all I will be subscribing to your rss feed and I hope you write again very soon!|

Thanks , I have just been searching for info about this topic for ages and yours is the greatest I have discovered till now. However, what concerning the bottom line? Are you certain about the supply?|

Hi just wanted to give you a quick heads up and let you know a few of the pictures aren’t loading correctly. I’m not sure why but I think its a linking issue. I’ve tried it in two different internet browsers and both show the same results.|

Thanks Sheryll for visiting us. We will check, thanks

I have been surfing online more than three hours as of late, yet I by no means found any interesting article like yours. It’s beautiful price sufficient for me. In my view, if all site owners and bloggers made just right content material as you did, the internet will probably be much more useful than ever before.|

Oh my goodness! Impressive article dude! Many thanks, However I am encountering issues with your RSS. I don’t know the reason why I am unable to join it. Is there anyone else getting similar RSS problems? Anybody who knows the answer can you kindly respond? Thanks!!|

Everything is very open with a very clear explanation of the challenges. It was really informative. Your website is very useful. Many thanks for sharing!|

Really appreciate you sharing this blog post.Really looking forward to read more.

I savor, cause I discovered exactly what I was looking for. You have ended my 4 day long hunt! God Bless you man. Have a great day. Bye