Four (4) Stroke Engines are described along with it’s various parts, working principles, advantages, disadvantages, etc. for basic understanding. A lot of images, diagrams are captured to visualize this engine. Let’s explore four (4) stroke engines!

What are Four (4) Stroke Engines?

Four Stroke Engine Basics

The four-stroke engines are part of the internal combustion engine. The four-stroke engine is one of the most used types of internal combustion engines. The name four-stroke comes from its working mechanism.

- Piston completes four complete separate strokes in this cycle. If you don’t know about strokes, a stroke means the piston travels along with the cylinder.

- These 4-stroke engines are used in almost every commercial as vehicles. Generally, gasoline-powered four-stroke cycles are more popular in lots of cars, trucks, etc.

- An operating process requires two revolutions (720°) of the crankshaft. Thus, the 4-stroke cycle completes 180° in a single stroke completing 4 strokes in 720°.

Four Stroke Engine Philosophy

The four-stroke engines have four strokes, namely, intake, compression, power, and exhaust stroke.

- These all 4 strokes have different working and responsibilities.

- To contribute to this operation, there are lots of engine parts are involved.

- It will be easy to understand the working of 4 stroke engines after knowing the parts contributing to the operations.

So, let’s know more details about the 4 stroke engine parts and their work. These parts are the same as for any engines with slight changes.

Components of 4 stroke engines

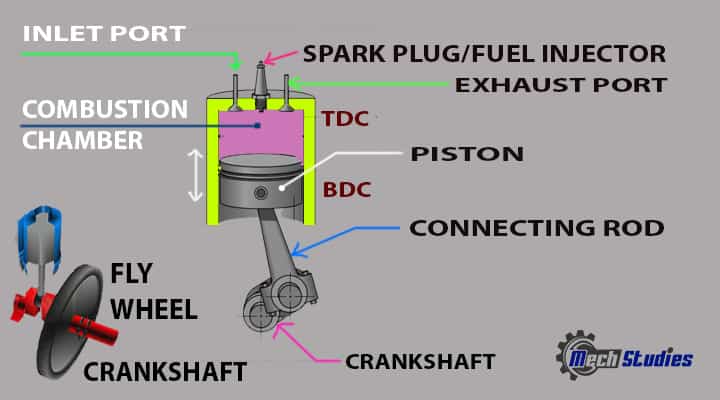

The four-stroke engine has the following parts,

- Engine Block

- Piston

- Connecting rods

- Crankshaft

- Cylinder head

- Valves

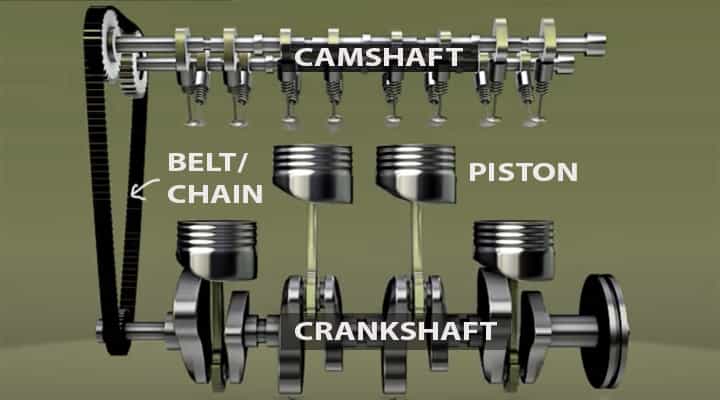

- Camshaft

- Lifters

- Timing chain/belt/gears

- Valvetrain

Engine Block

This is the center, or you can call it the foundation of the engine. The engine block holds the other parts of the engine. You can understand it as a big block containing various small blocks inside.

- This block holds the engine parts like cylinders, crankshafts, pistons, connecting rods.

- The block has given the large round holes known as cylinders.

- In those holes, the pistons slide up and down for the 4 stroke operations.

- The structure of the engine block contains coolant passages, oil galleries, and a crack the case.

Engine blocks are made up of cast iron or aluminium alloy material. Aluminium blocks are lighter, have better heat transfer, and iron blocks have advantages like durability and clearances.

Piston

The piston-like we have already discussed, it’s responsible for the strokes and operation of the 4 stroke engines.

- The piston slides up and down from the bottom dead center to the top dead center completing the 720 degrees of travel for one complete stroke.

- The piston has a connection to the crack shafts through connecting rods.

- The piston is used in almost all types of engines, and it’s a very important part of all engines.

- The piston has piston rings, which Seal the combustion chamber so that there is minimal loss of gases to the crankcase.

Also, it improves heat transfer and maintains the oil quantity between the piston and the cylinder wall.

Connecting rods

These are connected to the piston as well as to the crankshafts. They have the I-beam construction for getting strength.

- Its main and important function is to convert the reciprocating motion of the piston into rotation of the crankshaft.

- The big end of the connecting rod connects to the crank with the aid of the crank pin.

Also, there’s a pinhole through the bearing on the big end of the connecting rod, which accommodates lubricating oil to lubricate the piston and piston rings.

Cylinder head

Just like its name cylinder head is the top of the cylinder block. It acts as a cover for cylinders and pistons.

- The breathing of the engine is done from the cylinder head.

- It welcomes the air-fuel mixture into the engine and exhausts out of the engine.

- It is equipped with the valves which control the intake exhaust of the engine.

- It’s just like a normal breathing operation.

We will see it in more detail in the working of 4 stroke engines.

- ★Family time: with 300+ pieces of components (most of which are made by high grade Aluminum)! This kit will cost you about 5 hours to assemble. Buy one kit to share hours of joy time with your families.

- ★Educational: this assembly kit perfectly displays how each part of a modern v4 internal combustion engine are connected together and how they interact with each other. Displays the basic principle of a v4 gas engine. Great for your kid's science project.

- ★Wonderful shelf candy: it's a piece of art built by you from scratch. Put it in your office and it'll be a great conversation starter. Unique design and nice workmanship make this model a great decor for your desk or shelf.

- ★Another kind of Stirling Engine?: No. It's a model of a 4 cylinder, 4 cycle gas car engine that runs via two electric motors powered by a 500mAh rechargeable lithium battery. You can find a YouTube video of one being assembled on the channel "NDA Hack" titled "How to build Car Engine Assembly Kit - Full Metal 4 Cylinder" if you're curious.

Valves

We have discussed above a little bit about valves. The two types of valves are provided;

- one is the intake, and

- the other is the exhaust.

The intake valve welcomes the air-fuel mixture to flow inside. Whereas the exhaust valves flow the exhaust out of the cylinder. One of the valves is closed during the other operations.

Crankshaft

The first is the piston, then comes the connecting rod connected to the piston, and at the other side, it is connected to the crankshaft. It is also referred to as the crank.

- The vertical motion coming from the pistons with the help of connecting rods the crack shaft converts it into rotational motion.

- The crankshaft has a connection to the flywheel using bearings and journals.

A flywheel is one that transfers the engine power to the wheels through a transmission. Flywheel helps to reduce the pulsation, which happens in the case of 4 stroke cycle operations.

Camshaft

We have seen the functions of valves, but the opening and closing of the valves are controlled by the camshaft. It is basically a shaft as per the below image.

There is a lobe like the structure of the camshaft for each valve. It is located either in the engine block, overhead or double overhead.

Lifters

Lifters act as a link between the cam and valves. As the name shows, they lift when the camshaft lobe rotates. There are two types of lifters,

- Hydraulic lifer and

- Solid lifter,

Timing chain/belt/gears

These are used in different combinations to help connect crankshaft to the camshaft. They adjust the valve’s opening and closing timing with the movement of the piston.

Valvetrain

Just like the cylinder block contains all the parts required for the operation in its block.

- Same the valve train has the parts necessary for the opening and closing valves.

- It includes the above-discussed lifters. Also, springs, keepers, etc.

To understand the working of the four-stroke engines, there are some terminologies you should know. Here are some terminologies we are going to use in the understanding of the four-stroke engine working process.

Basic 4 Stroke Engine Terminology

The basic terminologies are,

- Bore

- TDC

- BDC

- Compression

- Cubic in displacement

Let’s try to understand in brief,

- Bore – The distance across the cylinder, or you can call it a diameter.

- Top dead center (TDC) – when the piston reaches its highest point in the cylinder, the position or point is known as the top dead center.

- Bottom dead center (BDC) – when the piston reaches its lowest point in the cylinder, the position or point is known as the bottom dead center.

- Compression – It has the same meaning as the word suggests—the squeezing of an air-fuel mixture when the piston moves from BDC to TDC, known as compression.

- Cubic in displacement – It denotes the engine size. You must have heard in vehicle specifications like the engine is 350cc or 1800cc etc. It shows the size of the engine in cubic centimeters. In simple words, it shows how much volume or air a cylinder can displace from BDC to TDC.

So now you know the basic terminologies used in the engines. Now the working of 4 stroke engines would be pretty easy to understand let’s know its working now.

Working of 4 stroke engines

So, before going into the working process, the 4-stroke engine has different cycles. Named as Otto cycle (pretty much popular in gasoline engines), diesel cycle, and Atkinson’s cycle. One of the most popular is the otto cycle. It is named after the scientist Nicolaus August Otto. The working principle of four stroke engine is explained in few steps,

(pretty much popular in gasoline engines), diesel cycle, and Atkinson’s cycle. One of the most popular is the otto cycle. It is named after the scientist Nicolaus August Otto. The working principle of four stroke engine is explained in few steps,

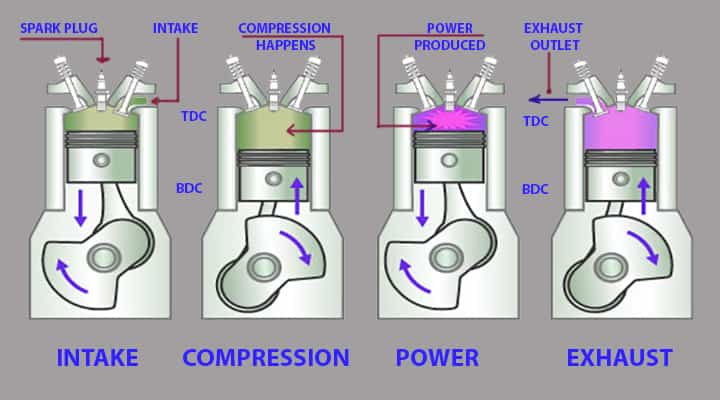

- Intake Stroke

- Compression Stroke

- Power Stroke

- Exhaust Stroke

Intake stroke

The first stroke in the four-stroke cycle engine is the intake stroke. The piston is at the top dead center (TDC) and then it moves down to the bottom dead center (BDC).

- The intake valve gets opened, which allows the air and fuel mixture to get sucked into the cylinder.

- As the intake valve is open, the exhaust valve remains closed.

- The 180 degrees of the piston is completed.

Compression stroke

The second stroke is the compressions stroke. The piston is at the bottom dead center (BDC) after the intake stroke.

- Now piston moves upwards to the top dead center (TDC), causing squeezing and compression of the air-fuel mixture.

- In this stroke, both intake and exhaust valves are closed.

- So, no air-fuel mixture is taken in or taken out.

- Another 180 degree that is 360 degree of piston traveled till now.

- Just before going into power stroke, the ignition event starts.

- The fuel is ignited using the spark.

- Just before completing the 360-degree piston, travel generally 20 degrees before the fuel is ignited by the spark plug.

Power stroke

This is the power generating strokes. By this stroke, the power is generated, and the ignited fuel is expanded.

- The piston rapidly moves from the top dead center (TDC) to bottom dead center (BDC).

- The force and motion created is then transferred to the crankshaft through a connecting rod.

- Both the vales are closed during this stroke, and now the piston is traveled 540 degrees.

Exhaust stroke

This is the final stroke in which the expanded gases are to expelled out of the cylinder. The piston is at the bottom dead centre (BDC) at the end of the power stroke.

- In the exhaust stroke, the piston moves upwards, also moving the gases with itself.

- The exhaust valve gets opened and the intake valve is closed.

- The gases are expelled out of the exhaust valves.

- The piston completes the 720-degree of travel.

Again, the intake valves are opened, and the new fuel is entered into the cylinder. The cycle continues again and again in seconds. The cycle keeps repeating. The order doesn’t change. A few things to note from the working of four-stroke engines.

- The piston direction has a distinct pattern, the intake valve only opens in the intake stroke, and lastly, the exhaust valves are opened only in the exhaust strokes.

- There are more advancements in four-stroke engines. The working we have seen above is the ideal working of the four-stroke engines.

Changes in Four Stroke Engine

There are various changes made according to the efficiency and stability requirements. Like,

- Igniting fuel before 20 degrees of completing the compression stroke and opening the intake valve just before the 10-15 degree of completing the exhaust stroke, and keeping open exhaust valve till 10-15 degrees after the starts of the intake stroke.

- These are the adjustments made to accommodate the stable, safe, and efficient working of the four-stroke engines.

Now let’s check out some advantages and disadvantages of four-stroke engines.

Advantages of 4 stroke engines

- More Torque: This is the main reason why people choose the 4-stroke engines. At low RPM, the torque made by the 4 stroke engines is better than the two-stroke engines. It is more reliable and quieter in operation than the two-stroke engine.

- Better fuel efficiency: The fuel is consumed only once in the four-stroke engines, which gives better fuel efficiency than the two-stroke engines.

- Cleaner operation: The four-stroke engines created less pollution due to no oil burning. Compared to a two-stroke, which makes lot of exhaust smoke due to the oil being burned and the fuel. In the four-stroke engines, the oil is kept away and separate from the combustion chamber, which ensures only gasoline gets burned during combustion.

- Longer life: The two stroke engines are made for high RPM speeds, which wears fast. The more engine runs, the quicker it will wear. The four-stroke engines have to complete 4 strokes at less RPM.

- No requirement for extra oil: Only the moving parts in the four-stroke engines need the lubrication.

Disadvantages of 4 stroke engines

- Complex Design: More reciprocating parts, more parts to worry about hence challenging to troubleshoot the problems due to intricate design.

- Not as powerful as two strokes: In the case of four-stroke engines, the power is generated once two revolutions. But in the case of two-stroke engines, it has the power stroke in every revolution.

- Expensive: It is evident that a more significant number of parts and intricate designs are costly than two-stroke engines.

- Frequent oil changes: There are more advances made in the four-stroke engines. Like, adjusting the valve timings and supercharging, etc. They are getting improved with every advancement made in their working as well as designs.

Conclusion

Hence, we have learned all about the four-stroke engine along with its parts, working principles. Hope, you like our content. Our Videos Refer YouTube