As technology leaps to unprecedented peaks, printed circuit board assembly has become a silent yet crucial production segment.

Mechanical insights help optimize these assembly lines to ensure their operational efficiency and meet the standards of a demanding market. Here’s how companies use these exceptional acuities to enhance PCB assembly efficiency.

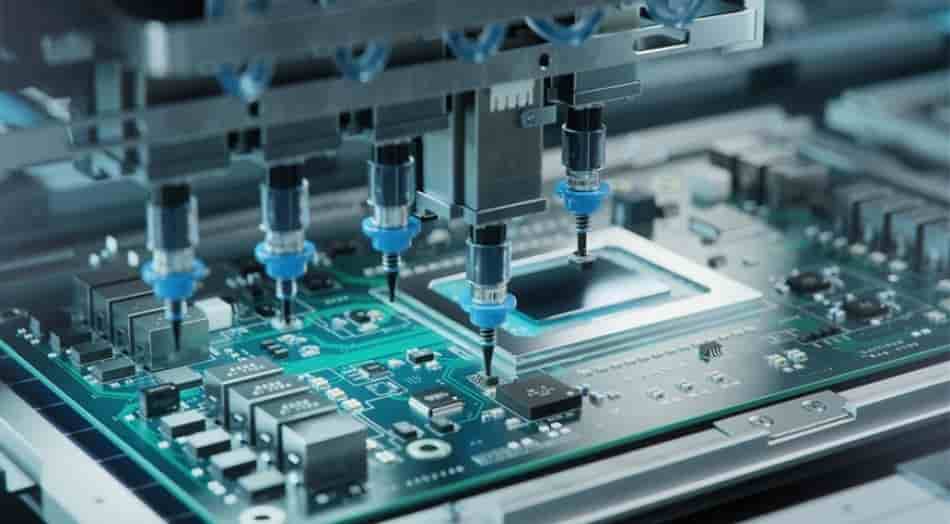

The Mechanical Backbone of PCB Assembly Lines

First, we must understand the core of PCB assembly lines. Its nature involves various mechanical processes – from component placement to soldering and inspection. The mechanical assembly line setup and the design and arrangement of machinery directly impact the final product’s production rate and quality. Understanding these processes is key to identifying bottlenecks and implementing improvements.

lines. Its nature involves various mechanical processes – from component placement to soldering and inspection. The mechanical assembly line setup and the design and arrangement of machinery directly impact the final product’s production rate and quality. Understanding these processes is key to identifying bottlenecks and implementing improvements.

Automation and Robotics

Automated systems and robotic arms can perform repetitive tasks with high precision if designed with a deep understanding of mechanical principles. Also, profound mechanic knowledge helps develop machines that can deliver tasks at speeds beyond the reach of human hands. Due to these, mechanical insights are highly valued in PCB assembly . This saves time spent trying to figure out which lead is connected to what hole!

. This saves time spent trying to figure out which lead is connected to what hole!

Material Handling and Flow

Mechanical insights help in designing conveyor systems and pick-and-place mechanisms that minimize the time and effort required to move components through various stages of assembly. These systems significantly enhance overall efficiency by reducing transit times and potential damage during handling.

Precision in Component Placement

Another vital element in PCB assembly is the accuracy of component placement. Signal integrity and performance heavily rely on meticulous placements, which are heavily influenced by mechanical engineering principles.

These highly designed placement machines must account for component size variations, board density, and alignment requirements. The precision offered by mechanically advanced placement equipment directly impacts the assembled PCBs’ reliability and performance.

Thermal Management in Soldering Processes

Careful thermal management occurs in soldering, a critical step in PCB assembly. Mechanical insights are utilized to design soldering stations and reflow ovens, ensuring uniform heat distribution and controlled cooling. This prevents common issues like solder bridging or cold joints, which can compromise the integrity of the product and the PCB company .

.

Custom Tooling and Fixtures

Custom tooling and fixtures, designed with mechanical engineering concepts, can greatly enhance the efficiency of PCB assembly lines. These tools are tailored to specific PCB designs, ensuring a perfect fit and reducing assembly time. They also help in maintaining consistency across batches, which is crucial for large-scale production.

Reducing Mechanical Stress

PCB assembly involves various mechanical forces, and managing these stresses helps avoid damage to the boards or components. Mechanical insights guide the implementation of stress-relief techniques, such as controlled handling and support fixtures during assembly. This minimizes the risk of cracks or component dislodging, which can lead to product failures.

Ergonomics and Worker Safety

Efficient assembly lines are not just about machinery and output; they also encompass the well-being of human operators. Applying ergonomics – a branch of mechanical studies – ensures that workstations are designed for comfort and safety. This not only improves the morale and health of workers but also boosts productivity and reduces the risk of errors.

Predictive Maintenance, Ergonomics, and Worker Safety

Mechanical insights contribute to improved predictive maintenance, ergonomics, and worker safety strategies. A thorough understanding of mechanical workings

By understanding the mechanical workings of assembly line machinery during maintenance, it is less of a challenge to anticipate potential failures. This reduces downtime and prolongs the life of the equipment.

Continuous Improvement and Innovation

As mechanical engineering develops, so does its application in PCB assembly. Ongoing research and development in mechanical technologies would soon lead to more improvements in assembly processes. Innovations such as 3D printing for custom tooling or advanced robotic systems for assembly and inspection are examples of how mechanical insights shape the future of PCB manufacturing.