In this article, we will learn what is cavitation, its basic definition, types, what are the main causes, effects, prevention, etc. Let’s explore!

What is Cavitation? Definition

Cavitation Basics

Cavitation is a well-known phenomenon of the deterioration of engineering materials functioning in water or other types of liquids at varied pressure values. A better understanding of all aspects of cavitation wear will enable more careful consideration in the selection of new engineering materials.

- Various technologies or techniques in the field of surface engineering and optimization of the design of constructional elements employed in the cavitation environment in sectors such as river and sea transport are also protected.

- Cavitation is generally defined as a phenomenon characterized by the collapse of gas bubbles in a liquid, with such bubbles produced as a result of rapidly declining pressure, resulting in the formation of shock waves with lengths of 0.1–0.2 mm and speeds of several 100 m/s, killing small surfaces of elements and resulting deep cavitation pits and craters.

- Cavitation can be costly and damaging if not regulated, resulting in high energy consumption and pump damage.

- Cavitation is a key cause of wear in several engineering contexts.

In this article, we shall get to know more about Cavitation, so let’s begin!

Definition of Cavitation

Cavitation was first seen during the sea trials of HMS Daring in 1885, when, due to previously unequaled propeller speeds, cavitation occurred. Cavities were forming in the water and they were the source of a tremendous waste of power and the cause of additional troubles,’ it was reported.

Soon after, it was discovered that these voids were the source of significant pitting and erosion of the propeller blades.

- Inertial cavitation and non-inertial cavitation are the two types of cavitation. “Inertial cavitation is the process of a vacuum or bubble collapsing fast and creating a shock wave in a liquid.”

- Non-inertial cavitation occurs when tiny bubbles in a liquid are driven to oscillate in the presence of an acoustic field whose amplitude is insufficient to cause total bubble collapse. This type of cavitation causes very little erosion than inertial cavitation and is frequently used to clean delicate materials such as silicon wafers.

In fluid mechanics, cavitation is referred to as hydrodynamic cavitation. Hydrodynamic cavitation is the phenomenon of vaporization, bubble formation, and bubble implosion that happens in a flowing liquid as a result of a fall and subsequent increase in local pressure.

- Cavitation most frequently appears when centrifugal pumps are used – these pumps rely on altering pressure inside the unit to generate a vacuum, pushing the liquid into the unit rather than pulling it in. Cavitation can occur in submersible pumps as well, but it is less common.

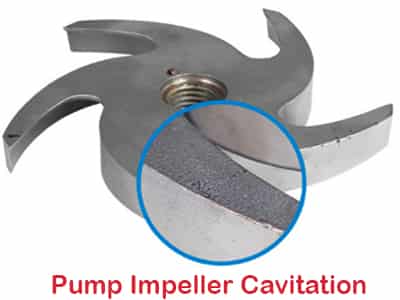

- Cavitation can have a significant detrimental effect on pump performance and durability. It can have an impact on many aspects of a pump, but the pump impeller is frequently the most severely harmed.

- A relatively fresh impeller that has been cavitated often appears to have been in operation for many years; the impeller material may be corroded and damaged beyond repair.

- Cavitation happens when a pump’s liquid converts to vapors at low pressure. It happens when there isn’t enough pressure at the pump’s suction end, or when there isn’t enough Net Positive Suction Head Available (NPSHa).

- Cavitation causes the formation of low-pressure air bubbles. The bubbles collapse when the liquid moves from the suction side of the impeller to the delivery side. This generates a shockwave that strikes the impeller, causing pump vibration and mechanical damage that could lead to pump failure.

- Different liquids have varying degrees of cavitation resistance because they are heavily influenced by the concentration of gas and foreign particles in the liquid.

Cavitation Mechanism

The following is a description of the cavitation mechanism:

- Any liquid contains either gaseous or vaporous bubbles that act as cavitation nuclei. Bubbles become a repository of vapors or dissolved gases when the pressure is decreased to a specific degree. As a direct result of this circumstance, the bubbles grow fast in size.

- As a result, when the bubbles enter a zone of reduced pressure, they shrink in size due to condensation of the vapors that they contain. Condensation occurs rather quickly, followed by local hydraulic shocks, sound emission, the breaking of material bonds, and other unpleasant events.

- It is believed that the contents of various admixtures, such as solid unwetted particles and gas-vapor bubbles, especially those on a submicroscopic level, which serve as cavitation nuclei, cause a drop in volumetric stability in most liquids.

- Surface degradation and material displacement generated by large relative movements between a surface and the exposed fluid are essential aspects of the cavitation wear process.

- Implosions occur when the pressure returns to normal (which is greater than the vapors pressure of the fluid), causing the cavity or vapors bubbles to burst. This bursting of bubbles generates shock waves, which cause work hardening, fatigue, and cavitation pits on neighbouring metal surfaces.

- Thus, cavitation refers to a phenomenon in which vapour bubbles (or cavities) in a fluid expand and contract as a result of local pressure variations. These variations can result in low pressure in the form of the fluid’s vapour pressure. This vaporous cavitation process happens at nearly constant temperatures.

Types of Pump Cavitation

There are various frequent causes of pump cavitation, therefore it’s vital to examine them when looking for solutions:

Suction Cavitation

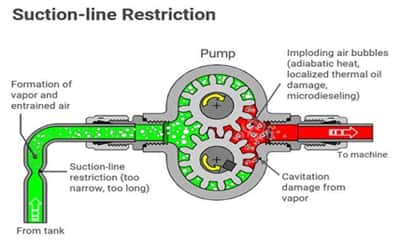

Suction cavitation happens when a pump is operating at low pressure under otherwise high-vacuum conditions. If the pump does not receive enough liquid flow, cavities or bubbles will form at the impeller’s eye.

- When the bubbles take over the pump’s expulsion face, the fluid condition changes, diminishing the bubble in the direction of the fluid and causing it to collapse near the impeller face.

- Suction cavitation has caused an impeller to lose enormous chunks of material that would normally be exceedingly tiny, causing it to resemble a sponge.

- This sort of cavitation can occur for a variety of reasons, including the ones listed below.

- Filters that are clogged, otherwise strainers

- A clog within the pipe

- Pump runs too far away from the pump’s curve.

- The piping design is bad.

- Suction is in terrible condition.

Discharge Cavitation

When a pump‘s expulsion force is extremely strong, discharge cavitation occurs. Because the expulsion pressure is high, the flow of fluid from the pump will be problematic.

Thus, it flows at exceptionally high velocity within the pump, between the impeller and the housing, causing a vacuum on the housing divider and the development of the bubble.

- In this type of cavitation, the collapse of bubbles causes intense shockwaves that cause the pump housing and impeller tips to break. The impeller shaft is being pushed into the break as a result of this form of cavitation.

- This sort of cavitation can occur for a variety of reasons, including the ones listed below.

- Strainers on the ejection side of the pipe are obstructed; otherwise, the filters are clogged.

- Pump runs too far away from the pump’s curve.

- The piping design is bad.

Other types of Pump Cavitation are as follows:

Vaporization

This is the most typical type of pump cavitation. It is also known as “classic cavitation” and occurs when a pump exerts velocity on a liquid as it passes past the eye of a failing impeller. When this happens, some of the liquid vaporizes, causing cavitation shockwaves to form.

Vane Syndrome

Vane Passing Syndrome is another name for this form of cavitation. It happens when an impeller has a significantly greater diameter than needed or when the housing has a thick covering. It happens when an impeller has a significantly greater diameter than needed or when the housing has a thick covering.

Turbulence

It happens when an impeller has a significantly greater diameter than needed or when the housing has a thick covering. Turbulence causes shockwaves and vibrations, which can eat away at solid objects over time.

Internal Re-circulation

When a pump cannot discharge at the proper pace, the liquid recirculates around the impeller, resulting in cavitation. The liquid is subjected to pressure variations in the system, which causes heating and high velocity, resulting in the creation of vaporized bubbles.

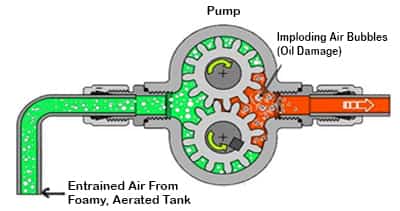

Air aspiration cavitation

When air is drawn into the pumping system through weak spots such as joint rings or worn-out valves, this type of cavitation develops. When air enters the system, it has no other route out and ends up creating bubbles in the liquid. Cavitation happens when bubbles rupture due to impeller pressure.

Signs of Cavitation

- Whenever a mechanical or structural problem arises, it is critical to maintain a dependable mechanism for examining the operation of the pump in order to detect early warning signs of cavitation.

- Cavitation can be caused by one or more of the following symptoms:

- Reduced Flow, or Force

- Noise

- Bearing or seal failure

- Unpredictable power consumption

- The progressive demise of an impeller

- Vibrations that occur unexpectedly

What are the Causes of Cavitation?

Cavitation occurs in a pump when the pressure and temperature of the liquid at the suction of the impeller equal the vapor pressure. It is possible to occur at low pressures and typical operating temperatures.

- Locally, it causes the liquid to convert to vapors and generates extremely high temperatures and pressures, which can reach 10,000K and 1GN/m2 respectively.

- During cavitation, bubbles form. As the pressure in the pump rises, the bubbles collide in the form of an implosion, which is just as powerful as an explosion.

- Shockwaves from the implosion pass through the liquid and strike the impeller, inflicting mechanical damage.

Cavitation Wear Process

Cavitation damage can cause the pump impeller, mechanical seals, bearings, and possibly other pump components to wear out. In other words, it will shorten the mean time between failures (MTBF), increasing maintenance expenses and pump downtime.

- The medium that produces cavitation wear is liquid. Cavitation wear does not need the presence of a second surface; rather, it necessitates a high relative motion between the surface and the fluid.

- This type of motion reduces the fluid’s local pressure. When a liquid reaches its boiling point and ebullition takes place, vapors bubbles emerge, resulting in cavitation.

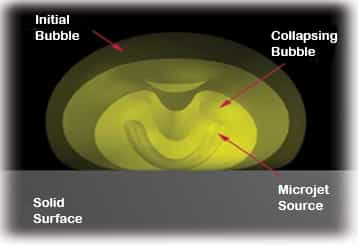

- Cavitation wear only happens in vaporous cavitation when shock waves and microjets erode the surfaces. As a result of gaseous cavitation, the material on the surface does not decompose.

- Cavitation erosion, vaporous cavitation, cavitation pitting, cavitation fatigue, liquid impact erosion, and wiredrawing are all terms for cavitation wear. Cavitation wear is analogous to surface fatigue wear in that material that is resistant to surface fatigue (hard but not brittle) is also resistant to cavitation damage.

- Each vapors cavity lasts only a few seconds because practically any rise in pressure causes the vapors in the bubble to instantly condense, causing the bubble to burst and produce a shock wave.

- This shock wave then collides with nearby metal surfaces, destroying the material links. The shock wave initially exerts compressive stress on the solid surface, and then, when reflected, exerts tensile tension normal to the surface.

- The collapse of a vapors bubble and the formation of a microjet is seen in above Figure.

- Cavitation is commonly encountered in areas where there is a hydrodynamic state characterised by a quick and large change in hydrostatic pressure. Because ebullition can happen as soon as the pressure drops, vapors bubbles form and collapse often and fast. The fluid’s entrained air and dust particles act as nucleation sites for the creation of vapors cavities.

- These nuclei can be microscopic gas-filled pockets in the cracks of the container or simply gas pockets on contaminating particles flowing freely in the flow stream. As a result, any confined fluid may contain enough contaminants to cause cavitation.

- Small cavities near the surface or flow field, where there is low pressure, indicate that cavitation has started. Bubbles, once formed, continue to develop as long as they remain in low-pressure areas.

- As the bubbles migrate into high-pressure areas, they collapse, generating enormous pressures and eroding any solid surfaces in their path. During the collapse, the liquid particles that surround the bubble quickly travel to its core.

- Kinetic energy from these particles generates high-intensity local water hammers (shock), which grow in intensity as the front moves into the centre of the bubble.

Cavitation Treatments & Prevention

Cavitation can be avoided most readily during the design stage, assuming no changes to the suction circumstances or liquid qualities throughout the operation. The key is to comprehend Net Positive Suction Head (NPSH) and include it in the design process.

To assist you to grasp this concept better, let’s split it down:

- Net refers to what remains after all deductions have been made.

- Positive is self-evident.

- The pressure at the pump’s inlet flange is referred to as the suction head.

When there is an issue with cavitation in a pump, the following measures can be used to prevent it.

Pump Selection

- The easiest strategy to avoid cavitation is to use the appropriate pump for the application. Cavitation increases when the pump head decreases or capacity grows, therefore choosing the right pump to maintain a positive range of Net Positive Suction Head available (NPSHa) above Net Positive Suction Head required (NPSHr) is the best initial step.

- A reasonable rule of thumb is to have pressure at the pump intake that is 10% higher than the pump’s specified NPSHr.

- Consider the pump design and always ask whether it meets the Net Positive Suction Head (NPSH) criteria when acquiring new pumps.

Discharge cavitation addressing

- When the pressure at the discharge end of the pump is too high, discharge cavitation occurs.

- High discharge pressure reduces the volume of fluid coming out of the pump, allowing high-velocity fluid to cycle between the pump impeller and the housing, resulting in cavitation.

Prevention

- Reducers should be kept as close to the pump as practicable.

- If a control valve is required, it should be installed on the discharge side rather than the suction side.

- Avoid areas where air or vapors can collect.

Prevention of Vaporization Cavitation

- Increase the fluid level all the way across the pump’s suction side.

- Increase the diameter of the eye at the impeller centre.

- Reduce the temperature ranges of the fluid, pump, and all other equipment.

- Insert a booster pump into the system to lessen the strain on the primary pump.

To Avoid Cavitation Due to Turbulence

- Increase the size of the pump suction line to reduce turbulence.

- Check that all of the components are in good working order, since this may lessen the strain on the fluid flow and volume.

To prevent Cavitation Due to Internal Recirculation

- Increase the pump’s confined discharge value to determine if there are any blockages within the pump.

- Remove any residual junk from the downstream filter.

- Check that the valve is properly installed, as this is a typical error in many systems.

- Determine whether the discharge valve is open or closed.

- Using all of the above-mentioned steps to handle the pump prevents cavitation and extends its life.

Periodical pump maintenance

- Because cavitation can cause a pump to implode, posing a significant safety concern, users are constantly looking for dependable solutions that allow them to foresee and prevent it. After correct pump selection, frequent maintenance is the most effective strategy to avoid cavitation.

Following steps should be added in routine pump maintenance

- Examine the filters and strainers. Filters and strainers that are dirty or clogged cause pressure to start building inside the pump. A maintenance schedule ensures that systems are in place to maintain the pump system running at full capacity.

- Examine the complete pump system design to verify that the best flow rate is available through pump elevation and downward flow wherever possible.

- Analyze the curve. Consider the task pressure requirements first, then the pump data to check if it meets the application.

- Keep an eye on pressure-sensing devices. Look for cracks or collapsed piping/hoses that could cause a disruption in the system.

Appropriate installation

The purpose of the installation is to keep net positive suction head available (NPSHa) greater than net positive suction head needed (NPSHr) by taking four essential variables into account:

Location of the Pump

Install the pump physically such that water flows freely into the pump suction inlet. Check that the suction lines going to the pump’s inlet are sufficiently slanted to ensure that the pump housing is inundated.

Placing the pump at a level lower than the water level in the tank from which it pumps, for example, employs gravity to maintain flooding suction, which prevents cavitation in many circumstances.

Pumps, particularly centrifugal pumps, perform best when the fluid travels in a continuous, laminar flow, and turbulence of any type affects pump efficiency, therefore putting the pump as close to the fluid source as feasible makes sense.

Length and diameter of suction pipe

In general, 12 cm of straight pipe is required for every centimeter of pump suction diameter. Connect 5-10 pipe diameters of straight piping to the pump inlet to maintain laminar flow. Within the final length of pipes, do not include elbows, reducers, valves, or strainers.

Connecting an elbow directly to the pump flange, for example, directs fluid to the outside curve of the elbow rather than directly into the impeller’s eye. Furthermore, the pipe layout must not put a strain on the pump casing, therefore pumps should never be used to support the piping for suction or discharge. Instead, use hangers and supports.

Suction lift (also known as the vertical distance from the water source to the pump inlet)

The suction lift can cause pumps to work harder than necessary, create turbulence, and reduce NPSHa. The option is to install the pump underneath the water level of the supply tank and adhere to piping design regulations.

Loss of Friction

When fluids flow through a pipe, friction between the fluid and the inside surface of the pipe generates turbulence, which slows the stream and causes a pressure drop. Pipe length, diameter, and flow rate all have an impact on friction loss.

By assisting in the maintenance of consistent velocity, good piping layouts help to reduce cavitation. Obstructions in piping layouts modify flow velocity, which changes fluid pressure and can lead to cavitation.

Cavitation in a Pump (NPSH Formula)

NPSH is an abbreviation for Net Positive Suction Head, and it is defined as the major difference between the input pressure level and the lowest pressure level within the pump.

The force decreases in the primary part of the pump before it increases the expulsion face in the direction of an upper level than the intake force.

Net Positive Suction Head (NPSH) is calculated using the formula,

NPSH = PT-Pv/ρg

Where,

- PT denotes the total pressure at the inlet.

- Pv denotes the fluid’s vapors pressure.

- P stands for density.

- G stands for Gravitational acceleration.

Learn details of NPSH

Detection of Audible and Visual Signals

- Sound or vibration are the most typical ways to detect pump cavitation. When this happens, there is an audible sound that sounds like cracking. The pump experiences greater vibration as a result of the bursting of the vapors bubbles, which may also be seen.

- Cavitation can be detected audibly, visually, by acoustical instrumentation, machine vibration sensors, sonoluminescence measurement, or by a drop or change in performance from that achieved under single-phase flow conditions (Loss of fluidity, rigidity, and reaction, for example.

- The wear rate generated by cavitating flow conditions can be many times larger than that caused by erosion and corrosion alone.

- Cavitation wear may degrade even the toughest materials, such as tool steels and stellites. Such damage can happen quickly and in a big way.

- The degree of damage caused by cavitation is determined by the pressure and velocity created by the collapsed bubbles. As a result of this pressure and velocity, the exposed surface experiences a wide range of intensities.

- Each imposition is only temporary; the impulse magnitudes and collapse timeframes are larger for bigger bubbles at given decreasing pressure differentials.

- As a result, the higher the tensile stress on the fluid (the smaller the static pressure), the greater the bubbles, the more severe the cavitation, and the larger the damage.

- When vapors bubbles develop and collapse, the impulses that ensue generate individual symmetrical craters and persistent material deformations when the collapse occurs near the surface.

- As a result, cavitation damage, like fatigue failure, has numerous active periods:

- Incubation period– Microcracks occur near grain boundaries and inclusions as a result of surface deformation, both elastic and plastic.

- Accumulation period– Crack growth is proportional to the amount of splitting, shearing, and tearing activity on the material.

- Steady-state period– For the remainder of the exposure time, the rate of crack nucleation and propagation becomes constant.

- In a fluid flow system (as opposed to an ultrasonic tank), vapors bubbles form where fluid tensile tensions (low pressures) occur, and vapors bubbles collapse where compressive forces may be placed on the fluid.

- As a result, the location where damage occurs is frequently distinct from the region where cavities form, leading to an inaccurate diagnosis of the disease.

- Cavitation wear is mechanical in nature and cannot occur until tensile and compressive loads are applied.

Advantages of Cavitation

- The advantages include high efficiency due to increased heat transfer and reduced friction due to faster movement.

- Cavitation can be used to produce micro-bubbles that aid in the flow and circulation of fluids in a liquid-filled tube. It is an effective means of cleaning and treating the liquid within the pump and turbines.

- The advantage of cavitation is that it generates a very clean cutting action on metals, ceramics, polymers, and composites. It’s been used to cut diamonds, glass, and a variety of other materials.

- Cavitation has proven useful in ultrasonic cleaning baths. It has enough force to counteract the adhesive force between impurity molecules and the clean surface.

- Controlled cavitation can be used to boost a chemical reaction. Cavitation is a method of homogenizing and mixing suspended particles in colloidal liquids.

- It is a technique used to boost the performance of high-speed maritime boats and projectiles. Cavitation in wastewater treatment entails the use of high-velocity cavitation to break down contaminants and organic compounds.

- The advantages of cavitation are used in the fields of material processing technologies and medicine. Cavitation is important in the destruction of kidney stones during shock wave lithotripsy. Cavitation is frequently employed in various medical treatments that use ultrasound, such as liposuction.

Disadvantages of Cavitation

- Excessive noise levels, potentially higher maintenance costs due to more frequent breakdowns, and inferior quality due to cavitation’s tendency to break down metals at a faster pace are all disadvantages.

- It produces too much noise for most businesses to employ as a commercial technique.

- It creates shock waves that can harm the apparatus. Cavitation can cause damage to system components such as bearings, valves, pumps, and pipes. It leads to a reduction in inefficiency.

- Cavitation is difficult on employees because it necessitates extra caution during maintenance and repair activities. Cavitation heats the material being treated, causing material degradation and even thermal damage to the equipment.

- Although the collapse of a small hollow is a low-energy event, highly localized collapses can degrade metals such as steel over time. Pitting induced by cavity collapse puts a lot of wear on components and can significantly limit the life of a propeller or pump.

Conclusion

Cavitation is widely recognized as the development of vapor bubbles in a fluid flow due to a pressure drop below its vapor pressure. Cavitation detection requires advanced technologies because of its rapid and complicated nature; otherwise, it can only be detected by its effects on the equipment, such as unexpected noise, vibrations, and material degradation.

There is no other way to avoid cavitation but to design the pump system correctly. During the design process, the value of NPSHa (which is independent of the pump to be chosen) can be simply determined. The NPSHa can then be compared to the NPSHr for the various pump types under consideration.

It is strongly advised that any necessary changes be made during the design stage since any additional expenses incurred will be far cheaper when compared to the costs of fixing a cavitation-prone installation. The greatest approach for avoiding cavitation is always good design.