What is a pulley system? Do you have any idea! In this article, we will learn the basics of the pulley, its definition, types, mechanism, various applications, advantages, disadvantages, etc. Let’s explore!

What is Pulley System? Definition

Let’s start with the pulley system basics.

Pulley System Basics

What is pulley? Let’s understand the basics. Ease is one of the most prominent factors that makes us efficient. Right from the evolution, we continuously worked on making our life easier. For this, we have invented some of the types of machinery and equipment that make chores relatively easy.

- For example, the invention of wheels has made us reach from one place to another in the minimum time possible.

- Likewise, numerous other inventions are pretty exemplary, and the pulley is among the same.

- Here we will discuss the pulley and the different adequate information that makes us worth using with par level efficiency.

This excerpt will cover the core definition and the subsidiary information such as the parts or components, use, benefits and backdrops with some of the precautions and safety points while using or installing the same. When we talk about the pulley, we perceive a small thing that makes the work easier.

- Pulley is an efficient item that we can come across in almost every industry. Whether it is a food processing plant, a construction plant, or a manufacturing division, we can see pulley applications.

- These applications are mainly based upon the bearing of heavy load.

- If you are unaware of the benefits of the pulleys or want to use pulleys for any reason, then this excerpt will be of great help.

- There are numerous kinds of pulley available as per the use, cost, and other parameters.

The pulley application is available in vivid sectors linked with the pulling and lifting of any objects that have massive weight or mass, even for less weight as well. Let us concentrate on the detailed information about the pulley to be aware of all the insights regarding the same and will start with the general description and definition of the pulley and why it is called a pulley.

Why it is Called Pulley or Pulley System?

From the name, we can deduce that pulley has been taken from the word “pull.”

- In general, pulleys are situated at an axle in the central position of the wheel that allows free circular motion around it.

- In this, the wheel has a groove on which the rope or any kind of cable can be easily placed.

- In this, the rope is pulled at one end, and the load can easily be lifted or moved in a specific direction as needed.

- This entire system consisting of pulley is called pulley system.

Pulley Definition

Pulley is just a mechanical component which has groove with rope or chain or belt which runs along the groove and helps to transfer a rope from a shaft and vice versa. While understanding the fundamentals of the pulley, the mechanism of the operation of the bicycle is quite apt. The working of the bi-cycle and its pedal can provide a holistic idea about the working principle of the pulley.

- Pulley work as an immediate link that is used for connecting a rotating shaft with the belt.

- It transfers the power with the help of friction.

- In other words, we can say that pulley is a machine that holds a flexible rope, chain, cord, or chain with its rim.

- These are the machinery that is used for transmitting energy and motion.

- There are different equipment where they are critically attached, such as belt drives.

- In these, the power is generated and transmitted between the shafts between endless circular belts, which effectively run over the pulley.

- The end of the ropes generates an upward pull which ultimately is used for lifting heavy objects.

- If the rope is affixed on numerous wheels, it increases the upward force, and with the additional wheel, the lift can help to cater heavy products with the same force applied.

There are three different kinds of pulleys available based on the positioning of the axle:

- A fixed pulley is among the pulleys which are equipped with the fixed axle.

- The moveable pulley is a pulley that has a movable axle.

- Compound Pulley is effectively a combination of both movable and fixed pulleys.

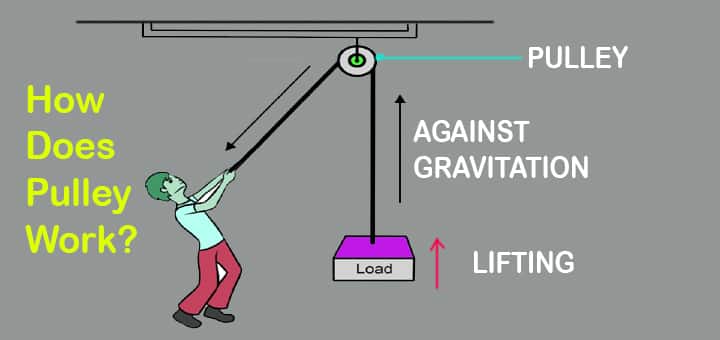

How Does Pulley System Work?

The working of the pulley depends on the number of pulleys used. With this, we can depict the core working and operation of the pulley. When it comes to one wheel pulley system equipped with one pulley around, that rope is placed.

In these cases, the load is attached to the pulley’s axle or is fixed at one end of the rope.

- The mechanism of one pulley system is quite simple as in this, the rope passes through a single pulley system and reaches the adjacent side.

- When we manually lift any of the weight, then there we have to exert an upward force which is against the gravitational force.

- This remains totally against the gravitational force of the earth.

- With the help of the pulley, there is a change in the force applied, which results in the reduction of the effort required for the lifting of the object.

In another case where there is an arrangement that includes a two-wheel in a pulley, the core importance is getting minimal effort to lift the load. There is a substantial increase in the mechanical advantage with the increase in the number of wheels of the pulley system.

- This is mainly the ratio of weight and the actual number of sections into which the rope is equally divided.

- This kind of pulley system is used where one pulley remains fixed while the other one is movable.

- In this, the force is applied downwards to lift any of the objects, which ultimately helps in reducing the Gravitational force acting on the load.

- Apart from that, in this arrangement, the rope remains at the 2x distance, which is basically due to the division of the space due to the two pulley system, which has two tension areas.

- In this, each section of the rope is moved to lift the weight.

When it comes to the four pulley system, then the working of the same changes a bit. With this, there is comparatively more reduction in the effort required to pull or lift the weight. This is because the rope is revolved four times around the whole. The mass of the object gets divided into four parts which makes it easier to pull the object. With this pulley arrangement, it is quite easy for anyone to pull the object with minimal effort.

Power Source for a Pulley System

After getting the idea of the working of the pulley system, it is pretty mandatory to clear the information about the power source of the pulley system. This part of the excerpt helps us to understand the power source of the pulley system. We will try to elaborate the same as much as we can:

- The pulley effectively gets its power from a distance; for instance, in a 2-pulley system, one-half of the force is for lifting the load.

- Here the rope length should be double the length of the desired lifting of the object’s length.

- This specifically depends on the concept of the work it is applied to.

- The magnitude of the effort applied specifically defines it.

While opting for maximum benefits, then the selection of the rope or cable and the correct type of pulley is quite essential.

- There are instances where people don’t emphasize these and do not get effective load-pulling capacity.

- For this, we have mentioned some of the attributes that are pretty important while designing or opting for an efficient pulley.

- Those attributes should be given importance in order to get maximum benefit.

- Pulley system designing with all the attributes will help to do the desired task at par level efficiency and increase the lifespan of the cables and the pulley they are attached on.

There are some of the common points on which the lifespan of both cable and pulley depends. If you want to extend the life of the pulley, then these points are going to be decisive. This is not only going to help design or select an effective one but also help minimize the cost associated with the installation of the pulley. With these points, the power generation to pulley can be clearer:

- The pulley system should have cable or wire that is re-equipped with the largest sheave diameter. This makes the cable quite strong for pulling the objects.

- The cable should be aptly supported in the groove of the sheave.

- The selection of the cable must be based upon the pulley system.

As per the expert recommendations, the pulley’s service life depends not only upon the cable but also on the pulley’s diameter; it is mandatory to choose the pulley of the diameter on which the cable shear groove can effectively rely.

To attain the maximum service life of the cable and pulley, the design should be in sync. In this, the basic functionalities play a significant role. Gradually we will try to look at some of the parameters that are quite effective while designing or selecting a pulley system.

What are the Main parameters for Designing a Pulley System

Different parameters should be considered while designing a pulley system. These parameters not only help in making it more efficient but also makes it cost-effective. The following are those parameters that should be given importance while designing a pulley system:

Diameter Ratio in Pulley System

The synchronization between the diameters of the pulley system is quite essential. If anyone who is working in the industrial sector then they are well aware of the diameter ratio .

.

- It is pretty mandatory to consider the largest pulley diameter in respect to the cable diameter.

- The D is the largest pulley diameter in this parameter, and the d signifies the cable diameter.

- Larger D:d ratio stands for the longer the cable has to withstand.

- While buying any pulleys, it is quite important to consider these recommendations for the proper ratio.

- Though it is not mandatory that all the pulley system works like that.

- Proper information is quite helpful while designing or buying a pulley system.

Optimal cable performance and efficient design in Pulley System

One of the essential parts of the pulley system is cable efficiency and its performance. For these to be maintained, the cable should be equipped with a jacket as well as lubrication.

- The need for smoothness and minimal cracks are pretty critical. For this, lubrication and the jacket play an essential role.

- It is recommended that we consider the highest quality of material for the jacket on the cable.

- The lubrication should also be at par, which should cover the whole wire.

- This helps in restoring the adequate functionality of the cable.

- The while pulley system undergoes friction at large, and the cables are the part that has to be in the mid of friction.

- The lubrication and jacket help in the proper functionality as well extended service.

- Optimal lubrication can help in minimizing the replacement services as well as expensive repair costs.

Grooving in Pulley System

As per experts’ recommendations, if the pulley system’s improper grooving, it will put utmost stress on the cable wire rope. This results in the premature wear of the parts.

- While designing the pulley groove, it is preferred to keep the grooving of the pulley at 150% tolerance for the cable rope.

- It can keep all the parts of the pulley system apt for maximum durability and provides extended life to the same.

- With these three parameters, we can easily design and maintain the pulley system for a long time.

- These parameters will provide practical and extended service life for the whole pulley system.

- It is quite preferable to take professional help while designing the pulley system for specific purposes.

Different Types of Pulley System

When we talk about the pulley system, it is quite mandatory to get information about its type. The commonly known pulleys are as follows:

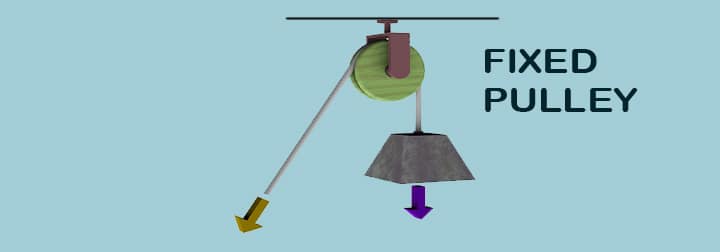

Fixed Pulley

The fixed pulley is the simplest kind of pulley in which the wheel is fixed to the point that works by altering the direction of the force applied.

The example of a fixed pulley is elevator.

Movable Pulley

The movable kind of pulley system is when the wheels come in motion and effectively load by applying less force.

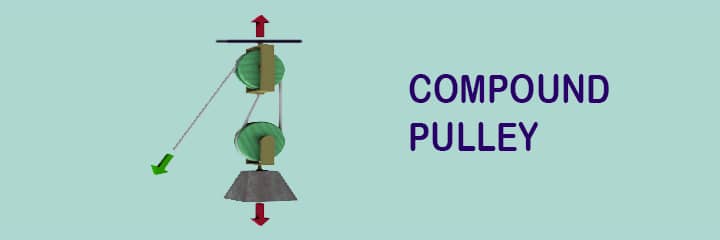

Combined/Compound Pulley

This kind of pulley has practical benefits and is equipped with the properties of both movable and fixed pulley systems. It is one of the pulley systems that involve minimal load and helps in completing the task.

- The above three kinds of pulleys are the common ones.

- On these principles, there are different kinds of pulley systems available.

- These pulley systems are commonly used in all kinds of industrial as well as different household use.

- Here we are also discussing the different commercially acclaimed pulley systems.

- With this information, it is pretty easy to choose as per the requirements.

Groove pulley

These kinds of pulleys are equipped with one or many grooves amongst their flange. These are present near the circumference, which helps in properly setting the belt.

- These kinds of the pulley are quite popular for their redundant usage, robust properties, simple design corrosion-resistant properties, and par level durability.

- These are used by those who want to attain maximum and efficient power of transmission equipped with low maintenance cost.

Timing belt pulley

These pulleys are popular for their pockets outside the diameter. These pockets are specifically to fit into the holes of metal belts.

- The timing belt pulleys are made up of lightweight and durable materials such as cast iron and aluminum.

- There are different kinds of pulleys available such as pilot bore, final bore, QD bush and taper lock bush type, etc. the pockets of the pulley help resist the slippage and limit the speed variation.

Flat Pulley

The wide usage of flat pulleys is in industrial applications. Preparing these types of pulleys needs high-quality materials.

- These are quite robust and durable.

- It is also resistant to corrosion and has a long span of service.

- The maintenance cost of this kind of pulley is relatively low, and it helps effectively.

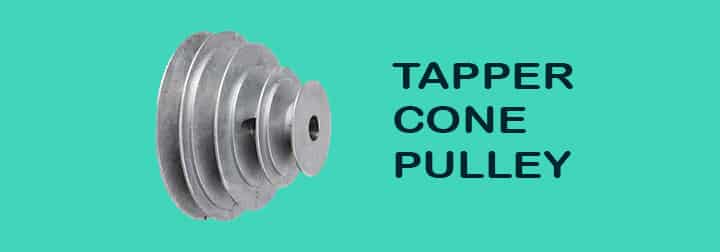

Taper cone pulley

The common use of taper cone pulleys is in paper mills. This is among the top-quality pulley and effectively transmits power to the attached parts from the source.

- The installation of these pulleys is relatively easy.

- This can also be customized as per the requirements.

- It is available on different balances, such as static and dynamic.

- These are the different types of pulley available in the market; however, some can be customized based on specific requirements.

- These requirements can be vivid as most industrial applications need a customized set of pulley systems for different kinds of work.

Pros and Cons of Pulley System

The pros and cons of the pulley system are pretty important as it helps in providing a holistic view of the same. Here we will discuss the compelling advantages and disadvantages which can make the above information quite productive:

Pros of Pulley System

- Pulley is quite useful and can effectively lift heavy loads.

- They can perform different tasks easily without making any noise.

- With this, it is quite easy to provide support to the long-distance moving ropes.

- The need of lubrication is not needed in the pulley system.

- Pulleys are pretty easy to use, and also these are cost-effective.

Cons of Pulley System

- The chances of slippage in the pulleys are quite evident. It uses friction to lift and pass the effective load, which are the core reasons for slippage. However, this can be minimized by using a timing belt pulley system. With this kind of pulley, it is pretty impossible to slip.

- Pulleys are not apt for very high power transfer at maximum rpm.

- The rope can quickly get wear due to creep and fatigue after an extended time of use.

What is the Formula for Pulley System?

Let’s try to understand the basic formula of the pulley system to solve different kinds of pulley problems.

Formula for Fixed Pulley System & Problem

Let’s consider, there is one fixed pulley, and two different masses, m1 & m2 are attached to the pulley through one common belt, as per the attached image.

Now, consider the below things:

- The pulley doesn’t have any weight (it needs to be neglected)

- Belt will not be extended or compressed

- Mass m1 moves towards down

- Mass m2 moves upside.

We all know that to solve any kind of force balancing, we have to draw the FBD i.e., free body diagram.

Let’s write the equations from the FBD to balance the forces,

- m1.g – T = m1.a1 . . . . . . . . . . (1)

- T – m2.g = m2.a2 . . . . . . . . . . . (2)

Now, both the masses are attached to a single belt. Hence, the displacement for each mass will be the same. This implies the acceleration will be the same for both the masses. So, we can write,

a1 = a2 = a

The equations become,

- m1.g – T = m1.a . . . . . . . . . . (1)

- T – m2.g = m2.a . . . . . . . . . . . (2)

By adding (1) and (2), we get,

- (m1.g – T) + (T – m2.g)= m1.a + m2.a

- (m1.g – m2.g)= (m1.+ m2) a

- (m1.+ m2) a = (m1.g – m2.g)

- (m1.+ m2) a = (m1 – m2)g

- a = (m1 – m2)g/(m1.+ m2) . . . . . . . . . . . (3)

Now, F is the force acting on the pulley’s own axis. The pulley is fixed, hence, the summation of all forces acting on the pulley is equal to zero.

- T1 = T2 = F (magnitude)

From FBD, we can write

- T1 + T2 – F = 0

- T + T – F = 0

- 2T = F . . . . . . . . . . . (4)

By subtracting (2) and (1), we get,

- (T – m2.g) – (m1.g – T) = m2.a – m1.a

- 2T – m2.g – m1.g = m2.a – m1.a

- 2T – ( m2 + m1)g = (m2 – m1) a

- 2T = (m2 – m1) a + ( m2 + m1)g

- 2T = (m2 – m1) (m1 – m2)g/(m1.+ m2) + ( m2 + m1)g

- T = ½ [(m2 – m1) (m1 – m2)g/(m1.+ m2) + ( m2 + m1)g] . . . . . . . . . . . (5)

A Sample Problem of Fixed Pulley System & Solution

Problem: One block with 0.80 kg of mass and a bucket with a mass of 0.40 kg. hung from a fixed pulley with a help of a belt. Neglect the mass of the pulley, the mass of the belt, friction.

- What is the value of acceleration in the system?

- What is the value of force acting on the pulley along its own axis?

Solution: Explanation, as well as the formula of the pulley, is elaborated for the fixed pulley.

Input data:

- m1 = 0.8 kg

- m2 = 0.4 kg

Now, from Equation (3)

Acceleration, a

- a = (m1 – m2)g/(m1.+ m2)

- a = (0.8 – 0.4) x 9.81/(0.8.+ 0.4)

- a = 0.4 x 9.81 / 1.2

- a = 3.27 m/s2

Now, to calculate the force in the system, F, to be calculated and for that take equation (1) or (2)

- T – m2.g = m2.a .

- T = m2.a + m2.g

- T = m2.(a + g)

- T = 0.4 x (3.27 + 9.81)

- T = 5.232 N

Mechanical Advantage for Pulley System

The most common formula for pulley is mechanical advantage. This formula is basically used for pulleys when it lifts some weight. So, what is the definition of mechanical advantage of pulley? Mechanical advantage means output force to the input force of any system. The ratio of load to the effort is defined as the mechanical advantage of pulley.

In case of two pulley system, mechanical advantage is defined as the ratio of driven pulley diameter to the drive pulley diameter. That means

Applications of Pulley System

When it comes to the application of pulley, then there is vivid usage; these usages can be of commercial or normal daily life. We will discuss both of them as it will help us get a holistic idea about the different kinds of pulley or pulley system applications.

Let us delve into the following applications of the pulley. In our daily life, we use this machinery at large. The basic reason for the usage of the pulley is to lift heavy objects. A normal pulley is made up of a cord, chain, wheel, and rope. Sometimes it remains input subconsciously, but at times we unknowingly use the same. With the following application, we will get a clear idea of where we use pulley:

- Pulley is used for curtain blinds, and it also helps in pulling up or down the curtain.

- One of the common uses of the pulley is in the water well, which is quite popular. In this, a bucket is pulled up with the help of a pulley, which remains filled with water.

- It is also used in the sailing boat for moving them around the path one desires.

- The most prominent use of pulleys is in sports equipment. For muscle exercise, all the equipment available uses the pulley system. Pulley effectively helps in controlling the angle at which the weights are to be lifted.

- One of the common uses of these pulleys is in elevators. It specifically works on an electronic pulley system. In these, numerous pulleys are used, and the counterweights help provide the lift system with optimal power and safety.

- Most of the construction work uses a simplistic kind of pulley. These pulleys are made of a wheel track that can easily be calibrated as per the need. It can be used for collecting debris or lifting heavy machinery.

- One of the most prominent uses of the pulley system is in theatres. The pulleys are used for operating the same. These are attached at a height and operated from sides of the stage from where they can easily raise and lower theatrical curtains.

- The pulley is also used in flower baskets as avid lovers of gardening use the pulley system to water the flowers. Apart from that, some systems can easily lower the flower pot for flowering and watering.

- While hanging, the chandelier pulleys are avidly used. It is pretty easy to clean and maintain the chandelier with the pulley system by lowering them to our reach.

- Rock climbers also use it for easy elevation climbing.

- Fishing is one of the chores that have practical usage of the pulley. This is among the common thing in which the pulley system is used.

Apart from all the applications mentioned above, numerous others make pulley efficient and the machine that makes the life of humankind quite simpler. It can also be used in adjustable clotheslines, kitchen rooms, motor pulleys in different machines such as sewing machines, bathrooms, sliding doors, hanging lights, etc.

Application of Pulley System in Commercial Life

- Pulleys are highly useful for industrial purposes. The use of pulley systems is almost in every industry. Most of the industry relies on the pulley system. The following are the commercial applications of the same that makes it quite efficient:

- Crane is among the most common of all the users in the commercial field. Almost every manufacturing and commercial plants use cranes, and these cranes are well equipped with a pulley system. This helps them to lift heavy loads.

- There is massive use of pulley systems in the sector of tall building washing companies. They wash those buildings from outside, and they can easily move up or down with the help of this pulley system.

- The elevators industry effectively used multiple pulley systems that are the core. The elevator’s mechanism critically depends upon the electronic pulley system that makes the pulley system quite useful.

Safety Measures While Working on the Pulley System

Pulley systems are simple, but they can be dangerous or loss-bearing if not handled properly. There are some of the measures that define safe practices while working or installing these pulley systems. The following are the points that can easily help us in keeping us and the machines safeguarded from different mishaps:

Knowledge of weight limit

Experts recommend that to check the SWL (specific weight limit) before reaching anything to the pulley. SWL is the information that helps us get the idea of the utmost workload a pulley can handle. In addition to that, it also signifies the angle, height, and different other factors that are pretty important for maintaining safety.

Optimal checking of the anchor system

The anchoring mechanism of any pulley system is quite important. It helps in the firm attachment of the whole system to a stagnant body. This body can be a building, tree, or anything other than that.

- It is important to check whether the anchoring system is up to the mark as it specifies the load capacity and support for the pulley.

- There are numerous kinds of anchoring systems available, for example, separate anchor, embedded anchor, etc.,

- We have to choose one per your requirement, but the attachment should be secure enough.

- It is recommended to et an idea about the minimum breaking strength. The breaking strength should be higher than the pulley attached.

- If there is more pulley load and low breaking strength, then it may cause serious accidents.

Wind intensity and direction

It is quite essential to give proper care towards the wind. As we know, the wind always remains there. In the case of windy weather, one needs to be more careful.

- An excessive windy atmosphere causes a hectic situation for the pulley ropes.

- If there is excessive wind, then one should stop working on the pulley.

- One can easily lose control if there are strong gusts involved with the wind. The pulley can easily hurt anyone working in the vicinity.

Barricading the area

It is recommended not to allow any person in the exclusion area. The exclusion area is the area in which the swing of the pulley takes place.

- The entry in this area should be limited due to the excessive movement, and people can get seriously hurt.

- It will be better if there is a marking in the exclusion area, and we should strictly restrict any unnecessary entry and exit of people or workers.

Inclusion of trained workmen

It is quite effective to employ only trained workers for the pulley system works. It provides effective protection and safety while working on a pulley system. An unknown or unprofessional worker can get seriously hurt while installing and using the pulley system inadequately.

Proper usage of safety gears

Protective equipment or safety gear while working on these systems is mandatory. Workers should be equipped with all the safety gear. Helmet, efficient dresses, protective shoes, gloves are quite necessary. It is pretty useful to get these products to the workmen so that there is minimal probability of physical injuries and legal obligations.

Conclusion

The invention of the pulley and its system has provided practical benefits for humankind. They have specifically made it simpler to lift heavy objects without much effort. With the proper pulley system construction, most of the works becomes optimally easier. They help to pull large weights or blocks upward. It also helps in some of the explorations, such as it is widely used in sailing ships.

These are the most simpler and widely used machinery in different sectors such as mechanical and industrial sectors. Gradual development in the pulley system throughout the time allowed people to attain the mechanical benefits of the pulley system.