The battery ignition system is explained along with the basic definition, understanding, different parts, working principles, advantages, disadvantages, applications, etc. Let’s explore battery ignition system!

Battery Ignition System

Let’s try to understand the basics of a battery ignition system! The working of the vehicle depends upon lots of components and their functions.

- In spark-ignition engines, the fuel is sparked using the spark plug.

- The spark plug generates a spark that ignites the fuel and further process will be carried out.

But how is that spark is created? That’s where the ignition systems come in. There are other ignition systems like electronic ignition. Here we are going to know about the battery and coil ignition system.

- The battery and coil ignition system are old and still used in lots of vehicles.

- It is being used in light commercial vehicles and two-wheelers bikes.

- It is one of the most common types of ignition systems and is usually one of the most used in two-wheelers.

There are various components that helps the battery ignition system to ignite a spark through the spark plug. We will know each components of the battery coil ignition systems. Generally, 6 volt or 12-volt batteries are used in these systems. There are some more ignition systems are available like magneto ignition system, distributor less ignition system, and electronic ignition system.

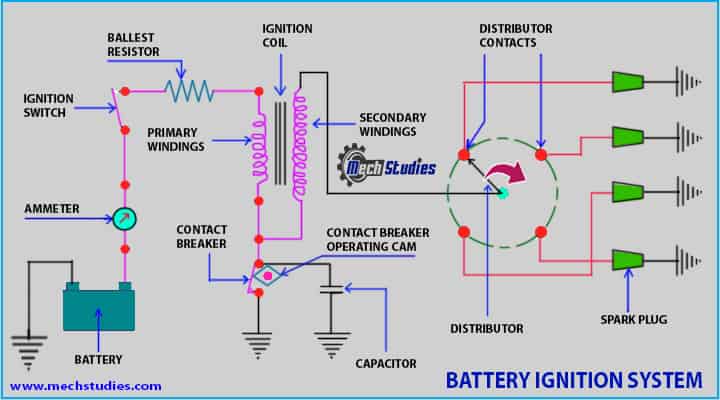

Parts of Battery Ignition System

There are various components of battery ignition system, these are as follows,

- Battery

- Ignition switch

- Ignition coil

- Ballast resistor

- Ammeter

- Contact Breaker

- Distributor

- Spark Plug

- Capacitor

- Primary winding

- Secondary winding

Description of Battery Ignition System Parts

Battery

The battery is one of the major components of this battery ignition system.

- It’s obvious because clearly, the name is the battery ignition system.

- So, the spark is created using the electrical energy, the electrical energy needed for the spark generation is stored in the battery.

- So, the battery gets charged using the dynamo driven by the engine. The battery is usually a 6V or 12 V battery.

The two types of batteries are used in the battery ignition system. One of them is a lead-acid battery generally used for light-duty vehicles. Other ones are the alkaline batteries generally used in heavy-duty vehicles. The lead-acid battery has cells in series with each cell having the potential of 2V.

Ignition switch

The ignition switch is kind of switch or starter to turn off/on entire ignition system.

- The connection of the ignition switch to the battery is made through the ignition coil.

- One end of the switch is connected to the primary winding of an ignition coil whereas another end is connected with the battery.

Ignition coil

The ignition coil is kind of a voltage transformer. It will step up the battery of 12V to higher voltage like (10000 V). It will step up the voltage which will be enough to generate a spark though the electrodes of the spark plug.

- The ignition coil has two windings primary and secondary windings.

- The primary is with the lesser number of coils whereas the secondary is with the highest number of coils.

- The construction of the same is made of a soft iron core surrounded by primary and secondary windings.

Talking about the connections, the primary one is connected to the battery terminal through the ballast resistor. We will see more about ballast resistor in upcoming point. The other end of the primary winding is connected to the contact breaker and the secondary winding. Now for the secondary winding one end is connected to the central terminal of the distributor and other one with the primary winding.

Ballast resistor

The ballast resistor controls the current passing through the primary windings. The ballast resistor is made of iron that has the property to increase electrical resistance rapidly by an increase in temperature at a certain limit.

- It is a self variable resistor, it will regulate the current from the primary windings.

- The resistor will get heated at a certain temperature.

- Now when the temperature increases above a certain range the resistance of the ballast will increase and the current flow will reduce.

- So, because of this current can be kept under safe value.

So, what will happen in the cold starting of an engine? The ballast resistor will be bypassed to allow more current flow in the primary circuit and thus generating a spark.

Ammeter

Ammeter is used for the measurement of the current.

Contact breaker

As the name suggests it will break the contacts. The contact breaker will break and make the contacts from primary circuit to the ignition coil.

- In this, the breaker points are held together by a spring and forced apart by the cams connected to the engine.

- When the contact breaker interrupts the current flow from the primary windings the collapsing current will induce large amount of voltage in secondary windings and thus spark is produced.

We will see the working of the battery ignition system in the next sections.

Distributor

The device which is used to distribute the ignition pulses to the individual spark plug is known as the distributor. If four spark plugs are used the distributor will be responsible for providing the proper spark for each of the spark plugs.

- There are two types of distributors available, one is brush type and other one is gap type.

- In case of brush type, it contains the carbon brush with a rotor arm that will slide over metallic segments that are embedded in the distributor cap.

- The distributor is made to synchronize with the contact breaker.

Spark plug

The spark plug is where the spark is occurred. Talking about its construction there are two electrodes separated by a proper cap. When the distributor will pass high voltage to the spark plug, high potential will generate a spark. Thus, the air-fuel mixture is ignited.

Capacitor

The capacitor is the one where the electrical energy is stored. It is fitted parallel to the contact breaker. In the capacitor, there are two plates that are metal and separated from each other through the air. If we talk about the main function of the capacitor, it is to prevent the arc from across the breaker point and when it is not connected to the primary circuit the induced voltage would cause an arc across the breaker point which is dangerous.

Primary winding

The primary windings are winded about the primary circuits. The primary winding has less turns as compared to the secondary windings.

- Approximately, 200-300 turns are available for the primary windings.

- The current flowing through the primary windings creates a magnetic field.

Secondary winding

The secondary windings have more turns as compared to the primary windings.

- Approximately about 21000 turns are available on the secondary windings of 40-gauge wire.

- These windings are insulated to withstand high voltage.

Now we have seen all the parts and components of the battery ignition system. So, how they will work together will be interesting. So, let’s start with the working of the battery ignition system.

How Does Battery Ignition System Works?

Let’s try to understand the working principle of battery ignition step by step,

- All the process starts when the ignition switch is turned ON. After switching ON the ignition switch the primary circuit will be closed and completed. Now current will start to follow through the primary winding.

- Because of this the magnetic field around the soft iron coil will be formed.

- The current will start flowing through the condenser when the contact breaker points open. When it closed the current will be flown through the contact breaker.

- The magnetic field induced will flow in the same direction as that of primary current. Now at a certain time the contact breaker will open and the sudden fall of current will generate very high voltage in the primary windings.

- Because of this high voltage the capacitor will come into charging state and when it will be fully charged it will start delivering current towards the battery. Now due to the reverse current flow magnetic field is induced in the primary winding.

- A very high voltage of about 15000 V to 30000 V will be generated in secondary winding. Now this high voltage will be transferred to the distributor by using high tension cable, this is where the rotor already rotates inside the distributor.

- So, at a certain stage of rotation, it will open the contact breaker points that will allow high voltage current transfer to the spark plugs.

- This much of high voltage current will reach to the spark plug thereby generating high intensity of spark inside the engine cylinder. Thus, the air fuel mixture will start to burn.

All these steps of working are completed in seconds. When you turn on your switch using your bike key and press the ignition switch. The whole process will get completed in just seconds and the vehicle will start. Let’s check some of the advantages and disadvantages of the battery ignition systems.

Advantages of Battery Ignition Systems

- The battery ignition system gives out more power output and also fuel efficiency which lasts for longer.

- Fuel efficiency is good.

- No moving parts are here.

- Spark intensity is good.

- The battery ignition system can provide high concentration of spark even in low engine speed at the time of engine starting.

- Low maintenance cost.

Disadvantages of Battery Ignition Systems

- The battery shouldn’t be discharged if it discharged there will be difficulties while starting of the engine.

- The battery ignition systems occupy larger space.

- When the speed of the engine will increase the efficiency of the battery ignition system will decrease.

- The shorter maintenance levels can be seen because the contact breaker points are subjected to mechanical and electrical wear.

Applications of Battery Ignition Systems

- The battery ignition systems are used in the car, bus, trucks and in bikes.

- Mostly, they are used in the light commercial vehicles.

Though there are electronic ignition systems, magneto ignition systems are available the battery ignition system is still used in lots of vehicle these days. As they are available in cheap and effective the battery ignition system is still relevant even being the old one in the game.

Conclusion

Hence, we have got a basic idea about battery ignition system along with the definition, parts, working principle, applications, etc. Please don’t forget to comment in the below comment box. Happy Learning!

Our Videos

Refer YouTube