Belt drives are described along with different types, working procedures, selection, advantages, disadvantages, power transmission, etc. Let’s explore belt drives!

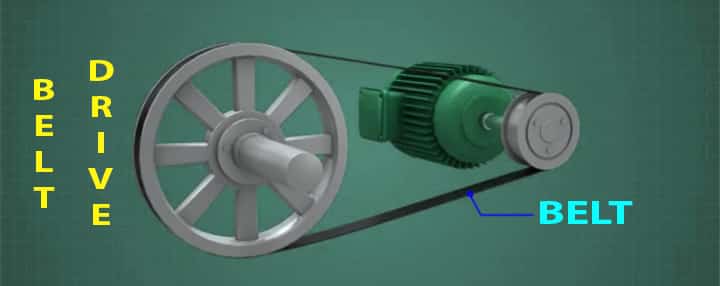

What are Belt Drives? Basics & Definition

Let’s understand the basics of belt drives!

Best Drives Basics

We are in the time zone where engineering innovations are on top priority. Every day there is a substantial increase in automation as well as effective advancement in the field of technology. When it comes to core machine knowledge, the theory of machines holds massive importance in gaining knowledge about all the different aspects of power transmission effectively.

- Power transmission has its own fair share of history as it is being used for more than 250 years in one way or another.

- In the initial stage of power transmission through belts, the use of flat belts which run on flat pulleys is quite popular.

- The continuous growth of belt drives helped us in the best possible ways.

- Later in the stage, V-groove pulleys are used for reducing belt tension. The advancement towards other types of belt drives keeps on regularly.

Requirements of Belt Drives

This article will provide holistic information about belt drives which are widely used in power transmission.

- It is important to get an understanding of this kind of power transmission approach as it is among those which can be attained with low cost, simple installation, minimal space, and effective flexibility.

- Belt-driven equipment is commonly used for all purposes.

- These are also effective for usage as it can easily be obtained through any local distributors.

- As compared to other options of drives these are less expensive and minimal maintenance.

We will discuss the core definition, kinds, materials, use, advantages and disadvantages of belt drive.

Belt Drive Definition

The belt drive is a component that is made up of flexible elements which help in power transmission.

- It is specifically used to nurture or transfer the power from one system to another system.

- This helps in transmitting power with the help of pulleys that rotate at different or same speeds.

How Does Belt Drives Work?

Basically, belt drives are equipped with two pulleys on which the belt is attached. The rotary motion or mechanical power is transmitted from the driving pulley to the driven one. This occurs due to the frictional grip present in between the pulley surface and the belt.

- The core working of the belt drives depends on both belts as well as pulleys.

- The part of the belt which has less tension is known as the slack side while the higher one is called the tight side.

- The pulling power of the belt generates the rotation of the driven pulley.

- The generated tensions in the slack and tight sides of the belt mainly based upon the contact angle.

- The belts should be arranged in a way so the slack side comes at the top while the right side comes below the pulley.

- This kind of arrangement helps to increase the angle of contact of the driven side belt.

- Though there are possibilities of slippage in the belt drives but this occurs only when there is lesser rotational speed.

- This effectively reduces the power transmission.

The overall process doesn’t make it suitable for wide application as desired component of the power transmission system.

Types of Belt Drives

When it comes to different kinds of belt drives we have mainly five prominent types that can be found. While understanding the types we have to understand that these belt drives are made up of two critical parts, one is pulleys and the other is belts. Here we are providing all the details regarding the types of pulleys as well as belts. The following are the types of belt drives:

- Open belt drive

- Closed or crossed belt drive

- Fast and loose cone pulley

- Stepped cone pulley

- Jockey pulley drive

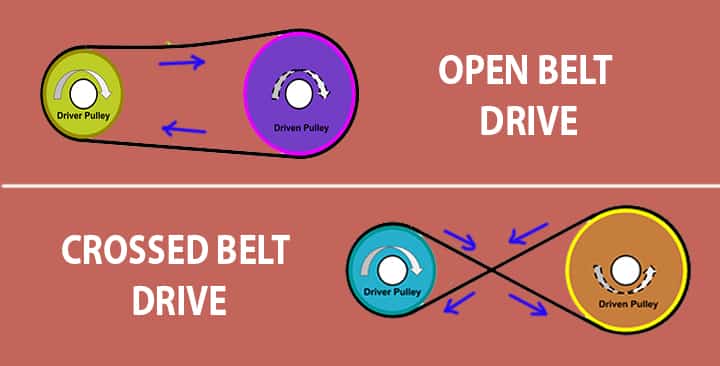

Open belt-drive

Open belt drives are the most popular kind of belt drives that are being used widely. In this the direction of rotation remains the same as the direction of driven and driving pulley.

- In this kind of belt drive, the rotation of shafts remains in the same direction.

- These shafts are arranged in a parallel direction.

- The distance between the driven and driving pulley is high and the below side is known as the tight side whereas the upper side is known as the slack side.

Crossed belt-drive

When there is a need of transmitting more power then these crossed belt drives are used. Though there is a limitation as it cannot run faster.

- If ruins at a higher speed, then there is a possibility of wear and tear of belts.

- In this, the shafts rotate in the opposite direction.

- Wear and tear generated when there is rubbing action of the belt at the junction side.

- To prevent wear and tear it must run at low speed and there should be more distance between pulley.

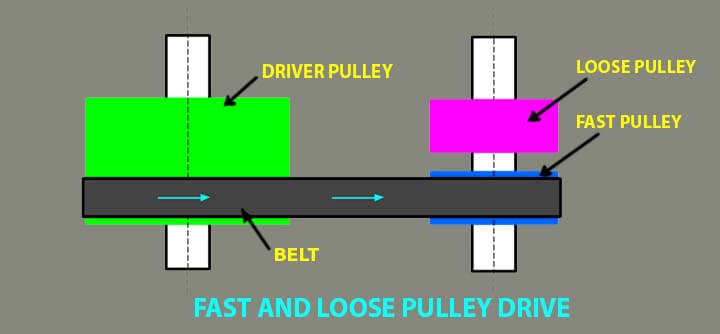

Fast and Loose Cone Pulley

This arrangement of belt drives is equipped with two pulleys; one is known as fast while the other is loose.

- The fast pulley is attached with the help of keyed joint while the loose pulley has a free-running motion on the shaft.

- The loose pulley is incapable of transmitting power.

- Where there is a need of attaching numerous machines with one power source then this kind of arrangement is used.

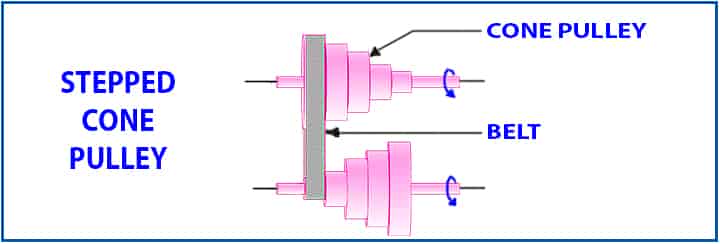

Stepped Cone Pulley

In this kind of belt, there are numerous pulleys attached to each other in an adjacent arrangement.

- These pulleys are of different diameters.

- Stepped cone pulley belt drives are effectively used in those machines where there is a need of changing speed or gear patterns.

- The same belt can be functional and we can shift to different pulley arrangements as per our need.

Jockey Pulley

Jockey pulley is one of the arrangements in the belt drive that helps us to get an increased angle of contact in open belt drive.

- These are basically used at the steering section of the systems.

- The increase in the angle of contact makes it useful to obtain increased power transmission.

- With this kind of pulley arrangement, one can get an increased and high-velocity ratio.

After getting a holistic idea of pulleys on which belt drives are mounted now it is the time to get an understanding of different kinds of belt.

Types of Belt

Mainly there are four kinds of belts which are widely used in belt drives. Following are some of them:

- Flat belt

- V belt

- Circular belt

- Timing belt

Flat Belt

Flat belts are equipped with rectangular cross sections.

- Use: Where there is a need for low power and high speed, these kinds of belts are used.

- Advantages: It has maximum efficiency and helps in the core working process. In addition to that it is somehow noiseless.

- Disadvantages: Improper alignment is the basic disadvantage. It needs proper alignment to produce effective efficiency.

V-belts

V-belts are those belts that are manufactured in a way that it provides fast movement on a pulley. This flat belt is equipped with a shape that holds the low tensioning force which effectively increases the pulley sidewalls.

- Use: These kinds of belts are widely used for industrial purposes due to their low cost, minimal installation problems and numerous sizes.

- Advantages: It comes in different sizes which is one of the most important benefits of this kind of belt. These belts are best suited for serious loads as well as high starting loads.it can also run at high speeds.

- Disadvantages: One of the major disadvantages of this belt is the banned ones which may get turnover.

Synchronous belts

These kinds of belts are mainly equipped with a toothed profile that has an alignment with the adjacent grooves in the pulleys. These are essential to provide positive engagement that helps in power transmission.

- Use: These are used in those places where there is a need for positioning, indexing, or a constant speed.

- Advantages: This kind of belt is capable of providing distributed load that helps in greater shear strength. This also helps in increased load capacity.

- Disadvantages: Alignment is one of the core issues. If these are misaligned in any way, then it may cause performance problems. Tension is also an effective parameter that helps in getting the maximum out of this kind of belt.

Link belts

These kinds of belts are equipped with removable links. These links are attached by a shape that has been twisted to another consecutive one.

- Use: These kinds of belts are used basically in the textile industry.

- Advantages: The basic advantages of link belts is its fast installation and vibration dampening attributes which makes it quite effective.

- Disadvantages: The cost of attaining and maintenance is quite high. While using it in high dust applications it should be covered.

Manufacturing Materials Used for Belt

It is very important to get an idea about the materials that are used for the manufacturing of belts. The following are the attributes that should be available in the materials:

- Flexibility

- Reliability

- Durability

- High tensile stress

- High temperature resistant

- Lesser weight

- Resistant to wear and fatigue

The above attributes can be found in different materials. Here we are also providing an idea of different materials that are used for making these belts. There are different kinds of materials that are used for the manufacturing of these belts:

- Leather belt: These are the most common types of belts used for different purposes. As the name suggests it is made up of leather. One of the limitations of leather belts is periodic cleaning and maintenance.

- Rubber belt: The rubber belts are also made of fabric that is covered with rubber that provides effective layering. These are basically used in paper mills, sawmills, etc.

- Cotton or Fabric belt: Fabric belts are effective and made up of folding fabrics. As per the thickness, it can be obtained by stitching.

- Plastic belt: Plastic belts are cost-effective but these are prone to deformation under high load.

- Balata belt: these belts are as same as the rubber belts but it has some of the attributes that make it quite effective. It can withstand acid also. The water-resistant nature if this material makes it suitable for wide usage.

How to Select an Effective Belt Drive?

After getting a holistic idea about the v-belts, there is a question that occurs in the mind of the user about how to choose an effective belt drive. For that the following attributes should be given preference:

- Positive drive should be considered while choosing the effective belt drive.

- The distance between the driven and driver pulley.

- The transmission power between the system.

- The design of shafts and other effective parts.

Difference between Belt Drive vs. Direct Drive

| Direct Drive | Belt Drive |

| Direct Drive requires much lesser space | Belt Drive Requires More space than Belt Drive |

| There is lesser loss of power in using Direct Drive | The loss of power is much more in Belt Drive |

| There are fewer parts that are needed to be replaced in Direct Drive | More parts have to be replaced in Belt Drive |

| Direct Drive makes a lot of noise while is use | Belt Drive makes lesser noise while in use |

| Direct Drive Motors are very weaker in than belt drives | Belt Drive motors are stronger when compared to Direct Drives |

| The cost of Direct Drive is less | Belt Drives are generally more costly |

Difference between Belt drive vs. Chain drive

| Belt Drive | Chain Drive |

| The belt drive is the preferred method for long and medium centre distances between the driven shaft and the drive shaft. | For short to medium centre distances, a chain drive can be used as a drive system. |

| If the friction force is greater than the load on a belt drive, slippage occurs. | Chain drive does not experience this type of slippage |

| A belt drive is a friction-type mechanical drive where power and motion are transferred from the belt to the pulley by using friction force between the belt and the pulley. | A chain drive is an engagement type mechanical drive that transmits power by sequentially engaging and disengaging sprockets and chains. |

| Because of frictional losses, belt drives are relatively inefficient in terms of efficiency. | Chain drives are known to be highly efficient, with an efficiency rating of over 95% in most cases. |

| Temperature and atmospheric conditions have an impact on belt tension. Consequently, belt drives also have a tendency to change their performance in response to external factors. | Temperature and atmospheric conditions do not usually affect the performance of chain drives. |

| A belt drive requires very little maintenance in terms of operation and maintenance | There are a number of things that must be maintained regularly, including lubrication of the chain drive. |

Difference between Belt drive vs. Gear drive

| Gear Drive | Belt Drive |

| In terms of engagement drives, gear drives are one type of drive system. | Among friction drives, belt drives are the most common. |

| Due to the fact that it is a positive drive, the velocity ratio remains constant. | Due to the frequent slip and creep that occurs in this system, it is a non-positive drive. |

| Gear drives are connected by rigid links between the driver and driven shafts. The two shafts are not interconnected by a flexible element that exists between them. | In belt drive, the driven and the driver shafts are interconnected by a flexible element that sits in an intermediate position (belt). |

| There is no protection against impacts and overloads provided by gear drives | It is important to protect the system from impact and overload by using a slip-in belt drive. |

| It cannot isolate the vibrations on the driven shaft from those on the driver shaft. | Using the intermediate flexible element, the driver shaft will be protected from vibration by absorbing it. |

| There is an easy way to achieve high speed reductions. | There is no steep reduction in velocity that can be achieved by it. |

| A large amount of torque and power can be transmitted through it | In order to transmit large torques and powers, belt drives are not the best choice. |

| Power and motion can be transmitted over short distances by using this device | In order to transmit power and motion over medium to longer distances, this device enables the transmission of power and motion. |

| There is an opposite rotation of the driver shaft and the driven shaft. The rotation of the gears in the same direction must be achieved with an additional gear. | It is possible to rotate both the driver and driven shafts in the same direction or in the opposite direction by using flat belt systems or closed belt systems |

| Despite small variations in temperature in the atmosphere, gear drive performance is not adversely affected | Temperature increases cause the belt length to increase, which results in undesirable slippage. |

| The transmission of power and motion over short distances is possible with it. | Belt Drive system is suitable for medium and large distance power transmissions as well as motion transmissions |

Slip and Creep in Belt Drive

Slip in Belt Drive

An open belt drive that rotates clockwise is assumed to be driven by a frictional grip between the belt and the pulleys. That is to say, the belt and the pulley are rotating because of a firm frictional grip between the belt and the pulley. As soon as this frictional grip becomes insufficient, there may be a possibility of the driver moving forward without a pulley mechanism attached to the mechanism. It is known as the slip in a belt; it occurs when the frictional grip of the driver is not sufficient.

Thus, slip is a term used to describe the relative motion between the belt moving in a pulley and the pulley rotating in a pulley. As a result, the velocity ratio will be reduced and the ratio is usually expressed in percentages. It is indicated by writing the letter S.

Creep in Belt Drive

Creep is the result of unequal stretching of the driving and driven pulleys on one side of the drive shaft, which results in the belt moving relative to the driving and driven pulleys. On the one hand, creep back on the driving pulley has the effect of reducing the speed at which the belt moves with respect to the driving pulley. On the other hand, creep forward on the driven pulley has the effect of reducing the speed at which the driven pulley moves with respect to the driving pulley. As a result, creep has a net effect on reducing the speed ratio in a way that is less than what is theoretically expected.

Since the belt material is elastic, it stretches unevenly on either side of the drive because it elongates more on the side that is tight than on the side that is loose. The driving pulley in this instance is given a belt that is longer than the object it is moving. The driven pulley rim must thus advance with respect to the belt as a result. In contrast, the driven pulley’s receiving belt is shorter than the one that drives it. Consequently, in relation to the driven pulley rim, the belt must creep slightly forward.

V belt vs. Flat belt

| V-Belt drive mechanism | Flat belt drive mechanism |

| Small distances between shafts allow it to be used for large power transmissions. | A large distance between the shafts makes it suitable for moderate power transmission. |

| As the pulley and belt have frictional grip, there is a possibility of slipping, so this is not a positive drive. | Due to the friction between the belt and the pulley, there is less chance of slippage. |

| Less space is required for this mechanism. | Large spaces are needed for this mechanism. |

| There is the possibility of obtaining high velocity ratios. | There is a possibility that a high velocity ratio will not be achieved. |

Advantages of Belt Drives

Belt drives are quite efficient as there are numerous advantages related to these. Here we are providing some of the basic advantages of these belt drives:

- The installation of belt drives is quite easy. Apart from that it can easily be removed.

- Cost associated with the implementation or installation of belt drives is quite low.

- The simplistic construction of belt drives makes it quite suitable than other kinds.

- The maintenance cost associated with this is also quite low.

- In belt drives the need of lubricant is negligible, you don’t have to use any kind of lubricant in these.

- It can drive power in any condition whether it is inclined, horizontal or vertical.

- The power consumption factor makes it suitable and provides an edge over other methods.

Disadvantages of Belt Drives

Though the advantages are quite efficient, but these belt drives are equipped with some of the disadvantages that should be considerate before using them:

- If you are using belt drives for power transmission, then there is more chance of power less due to slippage. Once in a while creep also happens which is quite a backdrop.

- It cannot be used for short distances.

- While using these you have to be ready for a preferred speed as it cannot go beyond a specific speed.

- The life of these belts are low.

- The chances of accidents due to breaking is more.

- These belt drives work below a specific temperature. If it exceeds then the chances of breakage or wearing up are more.

- The angular velocity doesn’t remain constant throughout the process.

Applications of Belt Drives

The belt drives are used basically for transferring power. Where belts are not used, if you see it’s used in many areas. It has effective usage in the mill industry as conveyors are the most popular usage of these kinds of belts.

Frequently Asked Questions for Belt Drives

What is the disadvantage of belt drive?

The disadvantages of belt drive are as follows

● The range of speed is limited

● There is not a high level of compactness

● There is a chance of a high level of power loss

● Compared to other power transmission modes, this mode of transmission has a shorter service life.

● The shafts and bearings of these machines suffer heavy loads as a result of their use.

● As a result of belt slippage, there may be a variation in the velocity ratio

How does a belt work?

The working of a belt follows these characteristics

● Belt drives work well as a result of the interaction between belts and pulleys, which is the core of the design.

● Based on the contact angle of the belt with the contact points, the generated tensions are mainly determined by the slack and tight sides of the belt.

● By arranging the driven side pelt in this way, you can increase the angle of contact between the driven side and the driven side,

● In this manner, the driven side pelt can be arranged so that it is wider than the driven side, thus increasing the angle of contact between the driven side and the driven side,

● Despite the fact that belt drives have the possibility of slippage, this only occurs when there is a less rotational speed than what has typically required

Which type of belt drive is the best?

There are several different types of belt drives, but V Blets are the best type of belts. As a result of using a trapezoidal cross-section V-belt, pulleys will have a wedge effect, causing more friction on the belts, and allowing the belts to transfer more power. There are many times when heavy loads require more than one belt to be joined together.

What is the belt drive used for?

Whenever the driving pulley pulls the belt, the belt is put under tension as a result. Furthermore, this belt tension, together with the static belt tension, is responsible for transferring mechanical force between the drive motor and the belt. There is little to no relative motion between the belt and the pulleys when belt tension is high and there is therefore no heat build up, slippage, or alignment problems as a result of high belt tension.

What are the 3 types of drive belts?

Below mentioned 3 types of drive belts:

1. Open belt drive mechanism

This is the simplest form of belt drive where a belt is wrapped around two or more pulleys to form the belt drive.

2. Stepped cone pulley mechanism

Driven by multiple diameter pulleys, stepped cone pulleys are called stepped cone belt drives because the pulley resembles a stepped cone.

3. Fast and loose cone pulley

In this mechanism, a fast pulley is mounted on the shaft of the driven device, and a loose pulley is mounted on the other shaft.

Where is the belt drive used?

Modern engines use belt drives to drive the engine control or ancillary components while transmitting the rotation of the crankshaft.

What are the advantages of belt drives?

● The belt drive’s smoother and quieter operation makes them superior to chain drives.

● Belt drives slippage and protects against overload.

● The cost of maintenance is comparatively low.

What are the other types of belt drives?

Below mentioned other types of belt drives:

1. Cross belt drive mechanism:

Drives like this are used when two pulleys are rotated contrary to each other, or when power transfer requires a greater wrap angle.

2. Jockey pulley drive mechanism:

In this kind of belt drive system, the smaller pulley determines the maximum force that can be transmitted.

3. Quarter-turn belt drive mechanism:

After making a quarter turn, a quarter-turn belt drive wraps around two perpendicular shafts. It is possible for quarter-turn belt drives to be used in situations where the rotation of the shaft is at the right angle.

What are the types of belts?

Below mentioned the various types of belts:

1. Flat belts type

Depending on the design of the belt, it may be a rectangular cross-section belt that rests on top of flat pulleys for operation and transmits power from one side only or from both sides.

2. Round belts type:

In a pulley, the U-shaped grooves or the V-shaped grooves are used to accommodate the round belts, which have a circular cross-section. As well as endless drive belts and endless round belts, they are also known as O-ring type belts or endless round belts.

3. Toothed belt type:

There is no friction involved in the transmission of power when using the toothed belt. While it is based on the teeth of a chain or a gear to transfer force, it is considerably quieter and requires less lubrication than chain or gear drives.

4. Link belt type:

A link belt is a type of belt that is made up of many individual links that are connected together. It is possible to attach and detach these links as needed to change the length of the belt as needed.

What are the parts of a belt called?

The components of a belt are as mentioned below:-

● The belt itself

● A belt tensioner

● Tensioning pulleys

● Deflection roller

What is a belt motor?

At a lower cost, direct drive motors can be substituted with belt drive motors in place of direct drive motors. In a belt drive system that utilizes pulleys that vary in size, speed and torque can be changed quickly and easily, removing the need for gearboxes and allowing shocks and vibrations to be absorbed more effectively.

What is the difference between the gear and the belt drive?

Compared to a belt drive, the gear drive requires a smaller amount of space, Lower friction, requires less maintenance & required regular fluids.

Compared to a gear drive, the belt drive requires a larger amount of space, Higher friction, High inspection is required and it requires a very less amount of fluid.

Conclusion

Those who want to get a holistic idea about power transmission through belt drives can get an effective idea with the help of this article. This article covers all the essential information about the bet drives. The belt drives are preferred in most of industries and mills which have effective material shifting or load carrying works. With this, it is quite easy to understand the holistic working as well as the advantages of this type of drive system. While using belt drives alignment carries a very important part. Though there is lots of information about these belt drives which we can cover in further articles.