Boiler mountings and accessories are described along with basics, different types, their workings to clear the basic concept. Let’s explore!

Boiler Mountings and Accessories: What Does it Mean?

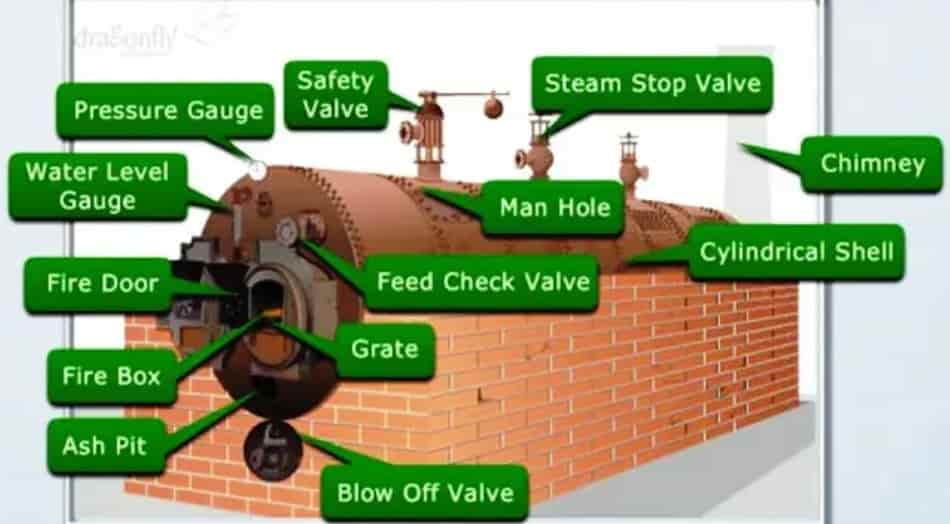

As the name suggests, boiler mountings and accessories are the associated components in the Boiler. Now, before going to mounting and accessories, let’s get a basic idea about the boiler.

- A steam boiler is a closed vessel that generates steam by applying heat energy to water.

- It is made up of steel in which combustion of fuel occurs to produce heat energy. Click here to know in detail about the boiler, its types, and applications.

Here we will explain some of the boiler mountings and accessories.

List of Boiler Mountings and Accessories & Types

List of Boiler Mountings & Types

These are the fittings and devices for the proper functioning and safety of the boiler. The boiler mountings are generally mounted over the boiler shell. They ensure the safe function of the steam boiler by controlling the fluid parameters inside the boiler shell. Without them, a boiler cannot function safely. There are mainly 7 mountings required to operate a boiler. We will discuss the function and working of each of them. They are named as;

- Water level indicator

- Pressure gauge

- Safety valve

- Steam stop valve

- Blow off valve

- Feed check valve

- Fusible plug

List of Boiler Accessories & Types

These are the devices that are used as an integral part of the boiler and help in running the boiler efficiently. Boiler Accessories are the auxiliary parts that control the fluid parameters outside the boiler shell. They improve the efficiency of the boilers. Different types of boiler accessories are used, some of them are;

- Air Preheater

- Superheater

- Economizer

- Feed pump

- Steam injector

- Steam trap

- Steam separator

Description of Boiler Mountings & Types

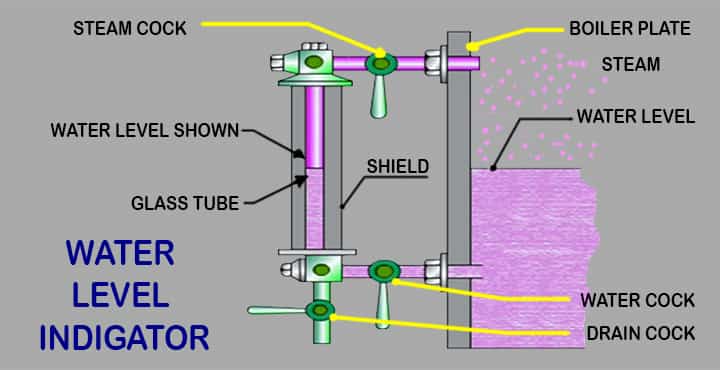

Boiler Mountings -1: Water Level Indicator

Function: As the name specifies, it is used to indicate the water level inside the boiler shell. Using this device, we can know the amount of water present in the shell of the boiler.

Construction: They are generally two in number and fitted in front of the boiler. The attendant of the boiler can easily see the water level. This indicator is a glass tube type device whose one end is connected to water space and the other to steam space through valves. It consists of a glass tube with markings and three corks as water cork, steam cork, and drain cork.

- The glass tube is protected by a cover.

- The water cork connects or disconnects the glass tube with water inside the boiler.

- The steam cork connects or disconnects the glass tube with steam.

- The drain cork is used to drain out extra water from the glass tube.

- This will help in ensuring the proper functioning of the water cork and steam cork.

Working: When the water cork and steam cork are opened, the water and steam will rush towards the glass tube. Through this, we can know about the level of water in the boiler. A ball type of safety device is used. Under normal operating conditions, the balls keep the ends open, therefore water or steam can reach the glass tube. If the glass tube is broken, the ball uses the pressure to close the ends. In this way, no water and steam can exit the boiler. For replacing the glass tube, the water and steam valves are closed first.

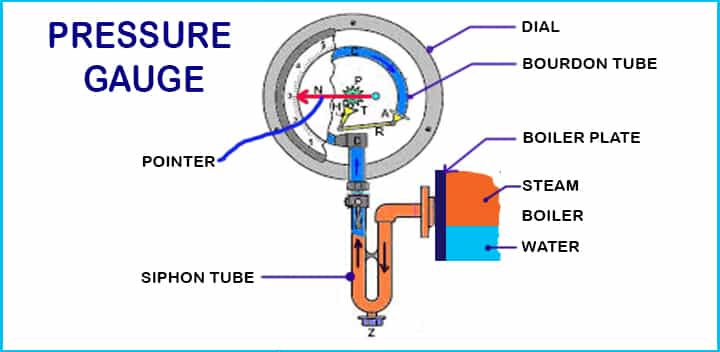

Boiler Mountings -2: Pressure Gauge

Function: The pressure gauge is used to measure the pressure of steam present inside the boiler. It is connected to the steam space of the boiler to give a pressure reading.

Construction: It is mounted on the front top of the boiler. The operator of the boiler can easily read it. A bourdon tube type pressure gauge is used. The gauge is graduated in units of Bar, one end of which is closed, and the other is connected to the steam space using siphon (U-tube). The siphon is filled with water, its purpose is to keep the gauge cool by preventing the entry of hot steam into the gauge.

Working: When we apply pressure to the oval bourdon tube, its cross-section tends to become circular. The free end of the bourdon tube tries to become straight. This causes the needle to move and pressure is indicated on the dial gauge.

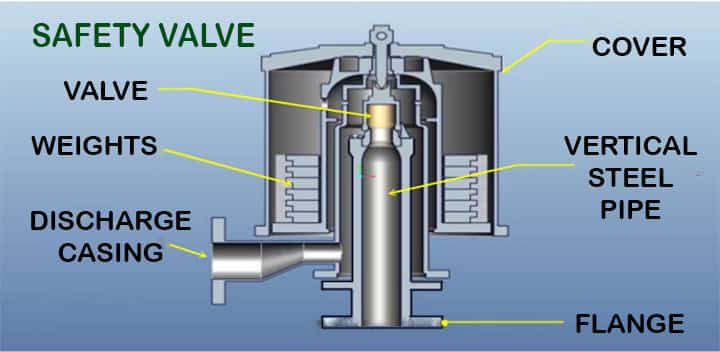

Boiler Mountings -3: Safety Valve

Function: The safety valve is used to prevent explosions due to excessive internal pressure. Generally, two safety valves are present on a boiler.

Working: A safety valve is a pressure relief valve. When the internal pressure inside the boiler exceeds its working pressure, it may cause damage to the boiler or may cause a severe accident. Therefore, the safety valve removes surplus steam from the atmosphere. In this way, the internal pressure inside the boiler shell is maintained at normal and the boiler operates safely.

Types of safety valves

Four types of safety valve that we can deal with are;

- Deadweight safety valve (i.e. Weight lies on top of pressure cooker)

- Lever-type safety valve

- Spring-loaded safety valve

- High steam and low water safety valve

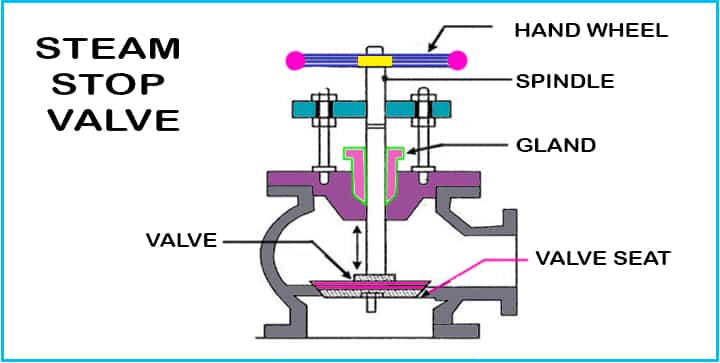

Boiler Mountings -4: Steam Stop Valve

Function: A Steam stop valve has the function to regulate the flow of steam from the boiler to the steam pipe. When required it can also shut off the steam supply completely. For power generation, the steam is taken out of the boiler through the steam stop valve.

Construction: It is fitted on the top part of the boiler with the help of a flange. It consists of a valve seat and nut. The valve seat is made of cast iron and the body of the valve is made from gunmetal. A junction valve is built up when the steam stop valve is placed over the boiler and connected to the steam pipeline.

Working: When the handwheel is rotated clockwise and anticlockwise, the valve will move up and down. By this required amount of steam can be taken out of the boiler for power generation or industrial process work.

Boiler Mountings -5: Blow Off Valve

Function: It is a simple hand-operated valve used to remove the muds and sediments at the bottom of the shell. It is also used to empty the boiler whenever required.

Construction: It is fitted at the bottom of the boiler shell. It consists of a gunmetal conical plug with a rectangular hole, spindle, and yoke. The plug spindle is rotated by means of a spanner. For fixing the spanner, two vertical slots are provided on the top of the yoke.

Working: When we open the blow-off valve, the water which is pressurized due to the presence of steam rushes out with high velocity. In this way, the water takes out the sediments and mud along with it. Therefore, mud or other settled impurities can be removed to keep the boiler clean.

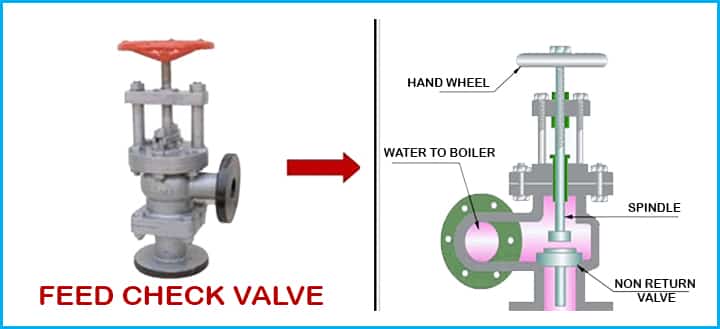

Boiler Mountings -6: Feed Check Valve

Function: It is a non-return valve used to feed the boiler with water. It is also called the check valve.

Construction: The feed check valve is fitted in the water space of the boiler just below the normal level of water. It consists of a non-return valve, spindle, gland, wheel, water inlet, and outlet pipe.

Working: It controls the flow of water from the feed pump to the boiler and prevents return flow from the boiler to the feed pump. The return flow occurs when the boiler pressure is more than the pressure of the feed pump.

Boiler Mountings -7: Fusible Plug

Function: The function of a fusible plug is to extinguish the fire in the furnace when the water level drops very low. By this, we can prevent explosions that may take place due to overheating of the furnace plate.

Construction: It is fitted to the crown plate of the furnace or over the combustion chamber. The fusible plug consists of two hollow guns and one conical plug. One hollow gun is fitted to the firebox crown plate of the furnace.

Working: Under normal conditions, the fusible plug is covered by water inside the shell. The water keeps the temperature of the fusible metal below its melting point. Whenever water level in the shell falls, the fusible plug gets uncovered from water and exposed to steam. Due to the heat of steam, the temperature exceeds its normal value. This results in the melting of fusible metal, therefore water from water space enters the combustion chamber to put off the fire. The boiler gets shut down so in this way an accident is prevented.

Description of Boiler Accessories & Types

Boiler Accessories-1: Air Preheater

Function: It is a device used to increase the temperature of the air which blows the hot gases in the steam boiler. It recovers heat from exhaust gases, otherwise, heat will be lost to the atmosphere.

Construction: Air preheater is installed between the chimney and economizer. It consists of a large number of tubes, arranged in the path of the flue gases. To increase surface area, baffles are provided in the air preheater. The soot hopper is used to collect soot during the cleaning operations.

Working: When air comes in contact with tubes at high temperatures, heat is transferred from tubes to air. The air temperature becomes increased, this hot air is then used to blow hot gases into the boiler. If we had used cold air, it would decrease the temperature of flue gases which would result in decreasing boiler efficiency.

Boiler Accessories-2: Superheater

Function: This device is a heat exchanger used to increase the temperature of the saturated steam without raising its pressure. A superheater is an important accessory used in the boiler.

is an important accessory used in the boiler.

Working: It is placed in the path of hot flue gases from the furnace. The heat given up by these gases is used in superheating the steam. Heat is exchanged between hot flue gases and generated steam. Some of the advantages of superheater are;

- Fuel consumption is reduced.

- Overall efficiency is improved.

- Losses due to condensation in steam pipes are minimized.

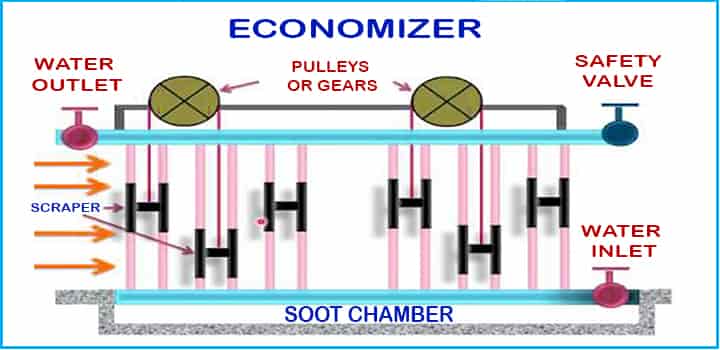

Boiler Accessories-3: Economizer

Function: It is used to heat the feedwater by utilizing the heat of exhaust flue gases before it leaves the chimney.

Construction: Economizer consists of large vertical steel or cast-iron pipes. Hot flue gases from the boiler pass over the vertical tubes.

Working: The feedwater is preheated before it enters into a boiler. Heat transfer takes place from flue gases to cold water rising in vertical tubes. Advantages of economizer are;

- Saving of fuel

- Long life of the boiler

- Increase in evaporative capacity of the boiler.

Boiler Accessories-4: Feed Pump

Function: This device is used to deliver water at a pressure higher than that in the boiler. Feedwater is pumped into the shell of the boiler.

Types of feed pump: There are two types of feed pumps.

- Reciprocating feed pump

- Rotary feed pump

Reciprocating feed pump: It is a positive displacement type pump. The duplex feed pump is the most popular type of reciprocating feed pump. It consists of a water pump and steam engine side by side.

Rotary feed pump: To deliver a large quantity of water into the boiler, rotary feed pumps are used. It is a high-speed centrifugal pump consisting of an impeller and casing.

Boiler Accessories-5: Steam Injector

Function: Whenever a failure occurs in the feed pump, the steam injector injects or pumps water to the boiler shell by use of steam.

Construction: It consists of a spindle, delivery cone, steam cone, combine cone, and a handle. The lower end of the spindle functions as a valve. The rotation of the handle causes the upward and downward motion of the steam cone.

Working: It has no moving parts and using the action of steam flowing through nozzles water is supplied into the boiler. This type of feed pump is common in locomotives.

Boiler Accessories-6: Steam Trap

Function: The function of the steam trap is to return the collected water in the steam pipe to the boiler due to partial condensation of steam. The steam is not allowed to escape and automatically returned to the boiler.

Construction: A steam trap is a disc or short solid pipe nipple having a small hole. It is installed at the lowest point of the boiler as steam condensate is collected at the lowest point.

Working: Steam is about 1200 times greater than hot liquid so the liquid is removed and steam is blocked. The majority of steam traps are operated either mechanically or thermostatically. They are open when condensate and inert gases need to be removed and remain closed when only steam is present.

Boiler Accessories-7: Steam Separator

Function: The steam separator as the name specifies has the job to separate water particles from steam. Saturated steam obtained from all types of boilers contains some water particles. It can affect the economy and efficiency of steam engines and steam turbines. Therefore, a steam separator is fitted before the steam engine or steam turbine with the purpose to make the steam dry and remove water from it.

Construction: It comes with inlet and outlet steam pipes; baffles and a water drain cork.

Working: The steam when entering the steam separator through the inlet pipe flows down. It strikes the baffles and gets deflected. As the water has a higher density compared to steam, it falls down to the bottom of the steam separator. In this way, water is separated from steam. This water is removed from the steam separator through a water drain cork.

Difference Between Boiler Mounting and Accessories

There are a few difference between boiler mountings and accessories, these are as follows,

| Sl. No. | Boiler Mountings | Boiler Accessories |

| 1 | Boiler mounting means these are mounted on the surface of the boilers | Boiler accessory means these are integral parts of boiler |

| 2 | These are essential parts and without these parts, bolier cannot work. | These are not essential parts and without these, the boiler can work. Mainly to increase the efficiency, boiler accessories are introduced. |

| 3 | These are mainly related to safety | These are mainly related to the efficiency |

| 4 | Helps to increase the longevity of the boiler | It helps to increase the efficiency, indirectly it also helps to increase the life |

| 5 | Need less space | Need comparatively more space with respect to boiler mountings |

| 6 | Boiler mounting controls the parameters of fluid inside the boiler | The boiler accessory controls the parameters of fluid outside the boiler |

| 7 | Examples: Water level indicator, pressure gauge | Examples: Economizer, air preheater |

Conclusion

This is a brief introduction to boiler mountings and accessories. If you find anything missing, feel free to write to us. We would love to receive your feedback and we are open to making any relevant changes to the content.