What do you think when we talk about if air bearings can uplift CNC Machine Efficiency? In an era where precision and efficiency dictate the pace of industrial growth, the integration of novel technologies into traditional systems has become imperative. Among these, the application of air bearings in CNC (Computer Numerical Control) machines emerges as a ground-breaking advancement. But what exactly does this mean for the world of manufacturing, and can air bearings genuinely improve CNC machine efficiency? Let’s glide into this fascinating exploration.

Air Bearings in CNC Machine Efficiency

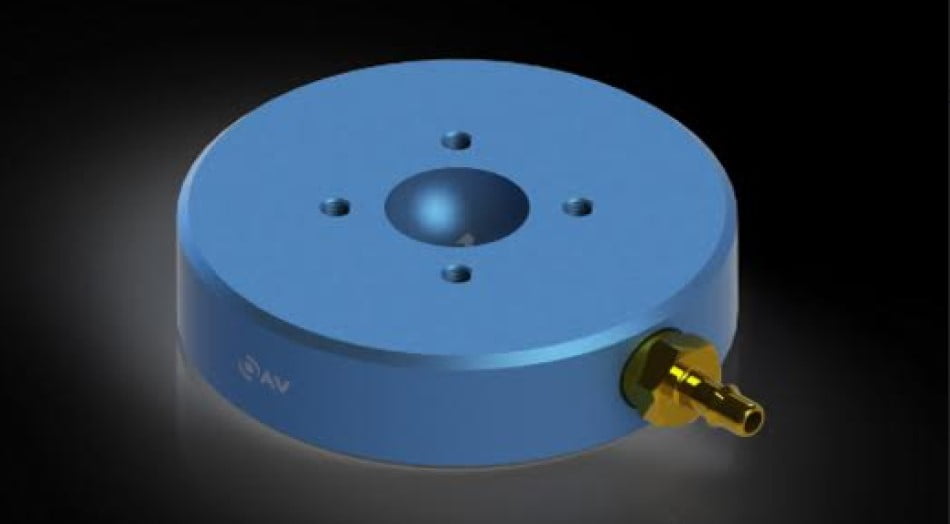

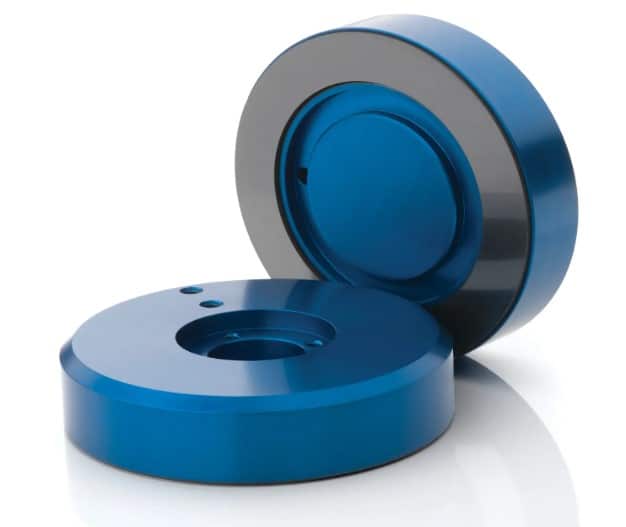

CNC, or Computer Numerical Control, is the automated control of machining tools (such as drills, lathes, mills, grinders, routers, and 3D printers) by means of a computer. Air bearings, on the other hand, are non-contact bearing systems that use a thin film of pressurized air to provide a virtually frictionless load-bearing interface between surfaces.

The Mechanics of Air Bearings in CNC Machines

Air bearings present a unique contribution to the world of CNC machines. Their application doesn’t merely reduce friction; it revolutionizes the entire mechanical structure.

Functionality and Integration

Air bearings operate by creating a thin film of air that separates the moving parts, virtually eliminating friction. The absence of physical contact ensures minimal wear and tear, which in turn prolongs the lifespan of CNC machines.

operate by creating a thin film of air that separates the moving parts, virtually eliminating friction. The absence of physical contact ensures minimal wear and tear, which in turn prolongs the lifespan of CNC machines.

Smooth Operation: By reducing vibration and noise, air bearings offer a smoother operation, allowing for more accurate machining.

Lower Maintenance: The non-contact nature of air bearings means fewer parts need replacement, thus lowering maintenance costs.

Advantages of Air Bearings in CNC Machines

Air bearings bring forth a multitude of benefits that enhance the efficiency of CNC machines. These advantages span across various aspects, from operational smoothness to economic considerations.

Enhancement in Precision

The application of air bearings in CNC machines leads to a substantial improvement in precision. The accuracy of CNC machining is often affected by factors such as friction and vibration, which air bearings effectively mitigate.

Improved Tolerance Levels: The reduction of friction allows for tighter tolerances, translating into higher quality products.

Reduction in Errors: By stabilizing the machine parts, air bearings minimize errors, resulting in more consistent output.

Economic Implications

Not only do air bearings increase the efficiency of CNC machines, but they also offer economic advantages.

Energy Efficiency: The reduced friction means less energy is needed for operation, cutting down energy costs.

Increased Productivity: With less downtime required for maintenance and repairs, air bearings enable a more continuous production cycle, increasing overall productivity.

Challenges in Implementing Air Bearings

While the advantages of air bearings are impressive, there are challenges and considerations to address when implementing this technology in CNC machines.

Technical Difficulties

Integrating air bearings into existing CNC machines can be complex and requires specialized knowledge.

Installation Challenges: Proper alignment and fitting are critical for optimal performance , necessitating experienced technicians.

, necessitating experienced technicians.

Potential for Air Contamination: The presence of contaminants in the air can affect the performance, requiring additional filtering systems.

Economic Considerations

The initial investment required for air bearings can be a barrier for some companies.

Higher Initial Costs: Though air bearings can reduce operating costs in the long run, the upfront investment may be substantial.

Cost of Training: Implementing air bearings requires staff training, adding to the initial expenses.

Future Outlook: The Sky’s the Limit

The integration of air bearings in CNC machines holds a promising future. Their benefits in efficiency, precision, and cost reduction are undeniable, and ongoing research continues to improve their capabilities.

Technological Advancements

The continuous development in air bearing technology promises even greater efficiency and performance in CNC machines.

Innovations in Design: Future designs are expected to reduce the complexity of integration and further enhance performance.

Environmental Sustainability: With lower energy consumption and less waste production, air bearings align with global sustainability goals.

and less waste production, air bearings align with global sustainability goals.

Market Growth and Acceptance

The market for air bearings in CNC machines is likely to expand as industries recognize their potential.

Increased Adoption: As the technology matures, more industries are expected to adopt air bearings, driving market growth.

Global Impact: The application of air bearings can have a worldwide impact on manufacturing , enhancing both productivity and sustainability.

, enhancing both productivity and sustainability.

Conclusion: Elevating Efficiency to New Heights

Air bearings have emerged as a transformative technology in the world of CNC machines. By reducing friction, enhancing precision, lowering maintenance costs, and contributing to environmental sustainability, they present a compelling case for implementation. Though challenges exist in terms of technical complexities and initial costs, the future of air bearings in CNC machines is bright, promising a new era of efficiency and innovation.