Centrifugal clutches are explained along with the definition, parts, working process, advantages, disadvantages, etc. Let’s explore the centrifugal clutch!

What are Centrifugal Clutches?

Let’s try to understand what is centrifugal clutch along with basics, definition, etc.

Centrifugal Clutch Basics

The operation of the vehicles depends upon lots of parts. The clutches are one of the parts that are needed for the working of the vehicles. The engagements and disengagement of the output shaft with the engine depend on the clutches.

- Centrifugal clutches are one of the automatic clutches available that uses centrifugal force for the operation.

- It uses the centrifugal force to engage or disengage the transition shaft and engine drive shaft.

- One side of the clutch is connected to the engine crankshaft and another side is connected to the gearbox.

- It is a part of automobile transmission systems.

Centrifugal Clutches Concept

Generally, this clutch is placed between the transition shaft and engine flywheel.

- If you don’t know about the centrifugal force, Centrifugal force is the force in which clutch shoes push outwards.

- Utilizing the centrifugal clutch enables the selection of normal torque motors for running loads rather than the selection of high torque motors for starting loads.

- Apart from automobile vehicles, they are used in chainsaws, sawmills, conveyors, compressors, etc.

- There are lots of components contributing to the working of clutches.

History of Centrifugal Clucthes

Centrifugal clutches were used in locomotives applications before 1958.

- Armstrong Siddeley first featured the centrifugal clutch in cars in 1936.

- Along with Armstrong Thomas Fogarty is also credited for inventing centrifugal clutch in small motor applications.

By using centrifugal clutches, we can start the engine under no-load situations. Let’s know the components of clutches and their details.

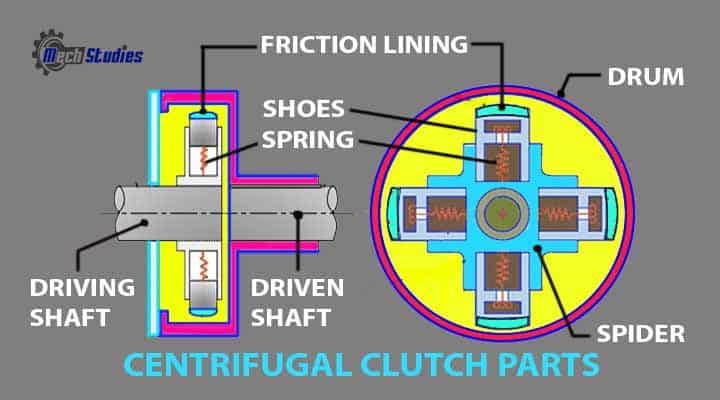

Parts of Centrifugal Clutches

The clutch has the following parts like,

- shoes,

- springs,

- spiders,

- friction lining,

- drum, etc.

Let’s try to understand each part,

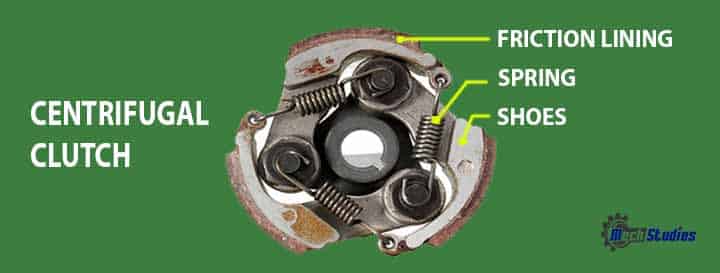

Clutch shoes

The clutch shoes slide in the guides, they act as a friction absorbers or consumers. The shoes are placed between the guides and the shoes slides between the guides.

- The shoes are provided with friction lining which is responsible for making contact at the time of engagement with the drum.

- The shoes can move radially outwards and are held in position with the help of springs.

- When the clutch shoes make contact with the drum the wear and tear of shoes are stopped by the friction linings.

Spring

The spring is attached to the shoes. As we have seen already the spring hold the shoe in position initially and shoes can move radially outwards.

- Shoes are connected or attached to the guide with the help of springs.

- The springs engage the shoe with the drum when the centrifugal force is high and disengages with the drum when the centrifugal force is less.

- Spring acts as an actuating element for the shoes.

Spider or guides

As the name suggests the guides are the one in which the shoe slides. It holds the shoe and the guide is controlled by the springs.

- They are mounted on the motor shaft or on the engine shaft known as the driver shaft.

- If we consider there are three guides then each guide will be separated by 90 degrees from the previous guide.

- The shoes slide between these guides and absorb the friction. Guides consist of springs and shoes.

Friction lining

We have seen it in the shoes section. The friction lining is provided on the clutch shoes. The friction lining with the curved shape help the shoe for connecting to inner part of drum.

Also, due to friction lining the shoes gets the grip on the inner side of the drums.

- The friction linings are important to avoid wear and tear of the shoes.

- They connect the shoe and the drum thus avoiding the direct between the shoe and the inner side of the drum.

Drum

All the above components are situated inside the drum. The drum is like housing for all of its components.

- The drum kind of acts like a protection to the parts like shoes, springs, guides, and friction linings.

- Drum connects the whole assembly to the driven shaft or transmission system.

- The torque coming from the shoes is transmitted through the drum.

Now we know all the components used in the centrifugal clutch system. Now let’s understand the working of the centrifugal clutches.

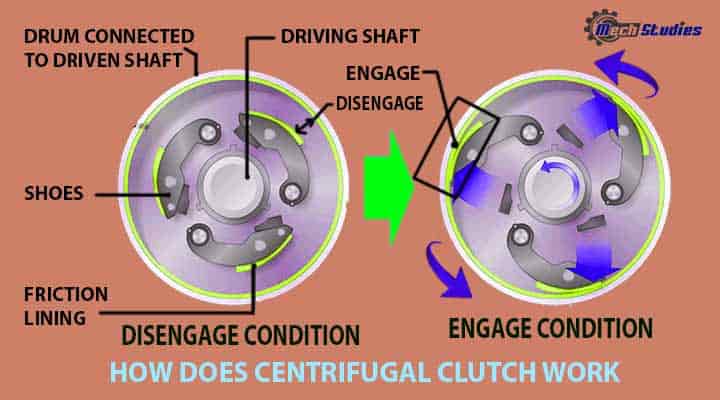

How Does a Centrifugal Clutch Work?

In case of the centrifugal clutches, there are two forces. One of them is a centrifugal force that pulls out the rotating body from its center. We all know about the friction force; this one is created due to the mating of two surfaces when they are moving in the opposite directions. Primarily, the working of the centrifugal clutch depends on the force coming from the driving member i.e. engine or motor.

Let’s understand how does centrifugal clutch work in a pointwise manner to understand it better.

- When the engine starts and rotates the centrifugal force is produced. The centrifugal force turns the driveshaft. This force also results in the activation of the transmission according to the engine RPM enhancements.

- When the input shaft rotates the power gets transmitted from the inputs haft. The increasing speed of the input shaft creates more centrifugal force and it is experienced by the clutch shoes.

- Now when the speed of the input shaft reaches up to a particular limit of speed centrifugal force exceeds the binding force created by the springs and thus shoes now start moving radially outwards as per the centrifugal forces.

- The spring force becomes less than the centrifugal force, now the shoes reach the inner side of the drum. The shoes have the friction lining, the friction lining gets pressurized at the inner side of the drum.

- Now as the shoe’s friction lining is connected to the inner side of the drum, the drum starts to rotate and the torque starts transmitting.

In racing karts, friction disks and clutch disks are used as motorcycle clutch. In these types, the same working mechanism is employed.

- When the speed starts to decrease and load increases and clutch gets disengaged to allow speed to rise again and it will re-engage the clutch.

- Now we know all the parts and the centrifugal clutch mechanisms it’s time to know the advantages and disadvantages of the centrifugal clutch.

- The working of the centrifugal clutch and semi-centrifugal clutch is the same.

The choice of clutches depends on various factors. Mostly, it depends on,

- vehicle type,

- the engine power and

- working environment of the vehicle.

According to these factors, clutch use is decided in the vehicles.

Advantages of Centrifugal Clutches

There are many advantages, as follows,

- The centrifugal clutches are automatic clutches, they automatically engage and disengages, so you don’t need any extra mechanical part or arrangement to control the clutch. It can automatically control the peak speed of an engine.

- If we compare other clutches with the centrifugal clutches the cost of the centrifugal clutches is relatively inexpensive. In the centrifugal clutch operations fewer parts are involved with no battery or extra component needed for centrifugal clutch to assists for its better working. This result lowered costs.

- In case of heavy loading or abnormal starting which can create sudden impact on the engine and it damages the engine. In this case using centrifugal clutch is much safer and better. Centrifugal clutch has the progressive engagement which helps to get the load progressively.

- Centrifugal clutches are specialized in shock less performance and smooth accelerations.

- The engaging speed can be controlled by the springs very precisely.

- Operation is simpler and requires less maintenance.

- The progressive speed control and engagement extends the life of centrifugal clutches.

Disadvantages of Centrifugal Clutches

There are few disadvantages of a centrifugal clutch, as follows

- The slippage in the centrifugal clutches cases the limitation in the transmission power aspects. If an engine is having low RPMs the centrifugal clutch will not be suitable for them because of overheating problems. The heat produced between the shoe and the drum causes the loss of power and can also damage the clutch.

- The different sizes of centrifugal clutches produce or create different peak speeds. Like, smaller-sized clutches provide faster speed.

- Due to overheating problems if the driving is rash it can cause permeant damages to the clutches.

- The centrifugal clutch activates when it reaches a particular speed. But if we want a attain a certain speed the clutch can not perform better. Even if the loading capacity goes beyond the capabilities of centrifugal clutch it can damage the engines. That’s the reason why the centrifugal engine is suitable for higher speed but can cause problems at the lower speed.

- The power is lost due to slippage.

- The oiling of the centrifugal clutch is necessary, to avoid overheating and keep the temperatures in check.

Applications of Centrifugal Clutches

The application of centrifugal clutches, as follows,

- Centrifugal clutch is primarily used in vehicles.

- It is also used in industrial equipment like machinery, mining, military, and manufacturing operations.

- Apart from automobile vehicles, they are used in chainsaws, sawmills, conveyors, compressors, etc.

- In the chemical industries, the centrifugal clutch is used in mixers.

- Lawnmowers, chain saw

machinery

machinery - Commercial two-wheelers like scooters and mopeds. Also used in go-karts.

- In the boats and paramotors for keeping the engine running during the stalling. Also, disengaging loads during starting or idling.

The centrifugal clutch construction is automatic mechanical. So, the adjustments are needed to be done for each specified application. Also, to get the optimum results with the centrifugal clutch it should be optimized with the particular engine.

Alternatives to the Centrifugal Clutches

There are some alternatives to centrifugal clutches, those are listed below.

Manual clutches

These are the clutches that needs to be operated manually by the driver. These are not automatically operated like centrifugal clutches.

Hydraulic clutches

As the name suggests these works on hydraulic principle. This clutch has oils to move the pistons back and forth and then engage the clutch.

Electrical clutches

These are operated on electric energy coming from the battery. When the battery passes the electrical current it creates magnetic field thus it attracts pressure plate and engages the clutch. If the disadvantages like slippage, peak speed, speed range are the concerns then the above alternates would be better than the centrifugal clutch.

The heating between the shoes and the drum is a lot more and causes the loss of power in case of centrifugal clutches. There is another type of centrifugal clutches named as semi-centrifugal clutches lets know the difference between the two clutches.

Difference between Centrifugal & Semi-Centrifugal Clutches

Talking about the semi-centrifugal clutches, these are not automatic clutches.

- Semi-centrifugal clutches are part of manual clutches that needs a clutch pedal to activate.

- Whereas the centrifugal clutches are automatic and do not need any pedal-operated force.

- The semi-centrifugal clutches operation is easy and there are less stiff clutch springs and operate only at low speeds.

- Whereas centrifugal clutches are suitable for higher speeds and they struggle at certain speeds.

- The semi-centrifugal clutches are used in high-powered engine and racing cars, where the efforts of drivers are needed to operate the clutches and control the vehicles.

Manufacturers of Centrifugal Clutches

There are a lot of centrifugal clutch manufacturers available in the market, as follows,

- BLM Automatic Clutch

- Hersey Clutch Co

- PETHE Industrial Marketing

- Clutch Engineering

- Lancereal and many more!

Conclusion

Hence, we have got a basic idea of centrifugal clutches along with parts, working principles. Any comment, please write in our comment box.