CNC Milling Machines are explained along with different parts, definition, working principles, diagrams, advantages, disadvantages. Let’s explore CNC Milling Machines!

CNC Milling Machines

Basics of CNC Milling Machine

Let’s learn the basics of CNC Milling machines! The new advancements in technology are making the manufacturing processes much easier. All the critical processes are now going in automated ways. Starting from the designing to the assembly the machines are being used because of the effectiveness and efficiencies. The most popular machines in the current era in the manufacturing world are the CNC milling machines.

- The computer numeric control (CNC) machine is widely used in the manufacturing, production sectors nowadays.

- The operations which were getting performed manually they are now automated with the help of CNC machines.

- Firstly, to know about the CNC milling machines, let’s know about the CNC and milling operations in brief.

What is CNC Milling Machine

CNC is a computer numerical control machine that is operated based on programmable codes. These programmable codes define various activities regarding the machines. Depending upon the codes mostly G-codes, the machine will move accordingly in precise movements. The CNC milling machines directly work as a computer-operated machine just like a robot.

- CNC with cartesian co-ordinates moves along the path according to the codes given in the program.

- Because of those coding, programmes, the CNC milling machine works as a most precision machine.

- There are different ways a CNC machine will perform the work either as additive or subtractive.

So, basically CNC will operate via programmable codes with high accuracy and precision.

What is Milling Process

The milling a machining process that uses rotary cutters to remove the materials. It advances into the work piece to remove the material. The removing of material is done in various axes, speeds and pressures. Milling operation is one of the most common operation or process used in the manufacturing sector.

There are lots of types of millings we will discuss them shortly. In the 1960s milling machines were changed to milling machine centres. Later they were equipped with automatic tool changers, tool magazines, CNC additions and other equipment’s.

The CNC milling process is suitable to materials like metal, plastic, glass and wood for production of custom parts and custom designed products. There are different types of milling processes done by the CNC milling. Let’s see the components of CNC Machine and how the CNC milling machine operation is completed and what steps are included.

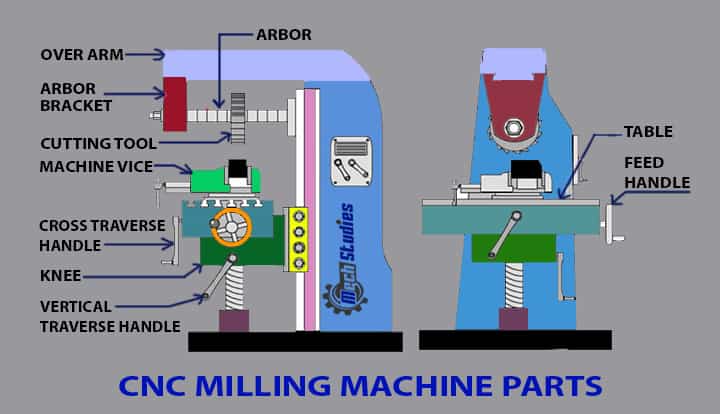

CNC Milling Machine Parts

There are various components of the general CNC milling machine. Let’s see them one by one.

01. Column

The column in case of the CNC Machine is to provide the support and structure to the other machine components. Column acts as a support structure for the milling machine.

02. Machine interface

We already know the CNC machines are computer numeric control machines. The operators are needed to load, initiate and execute the programs in the CNC milling machines. The machine interface enables the operator to do the same.

02. Knee

The knee is kind of adjustable component fixed to the column. Knee provides the required support to the saddle and the worktable on which the work holding device is mounted. The knee can be adjusted in Z-axis it can be lowered or raised according to the requirements.

03. Saddle

The saddle is mounted over the knee. Just like the knee supports the saddle the saddle supports the worktable. Also, the saddle can be moved parallel to the axis of spindle. It can help workpiece to adjusted horizontally.

04. Worktable

It is located at the top of saddle. It consists of work holding device on which the workpiece is mounted. Work holding devices like the chuck or vice is used. The worktable can be adjusted horizontally, vertically both or fixed at one direction according to the work requirements.

05. Spindle

The spindle is rotating device which holds the machine tool. The spindle is driven by the electric motor.

06. Arbor

It is a kind of shaft that is inserted into the spindle in horizontal milling machines. Multiple machines can be easily mounted on this shaft. They are available in various sizes, lengths, and diameters according to the specifications.

07. Ram

The Ram is generally found in the vertical milling machines. These are located on the top and affixed to the column. It can be adjusted for the different position of milling operations.

08. Machine tool

This is the major part which accommodates the milling operation. The tool is held by the spindle and it performs the material removing operations. There are various types of cutters are available like multi-point cutting tools, single point cutting tool. Depending upon the requirements needed in the workpiece the cutter is selected. Milling machine are also used for drilling, boring, reaming tools for other operations.

There are various types of milling machine are available. They are widely classified according to the number of needs and purposes. Let’s discuss the most common types of milling machine used nowadays.

Types of CNC milling machines

01. Vertical milling machines

The vertical milling machine is a 3-axis milling machine. It has a table acting as a work surface and spindle. In vertical milling machines, as the name suggests, the spindle axis has a vertical orientation. The cutters rotate on its axis held by the spindle. The vertical CNC milling machines are further classified into two groups,

- Turret mill – The turret mill has a fixed spindle and the table has a movement of perpendicular and parallel direction to the spindle axis. Some turret mills are equipped with the quill, it allows the milling cutter to be raised and lowered.

- Bed Mill – In the case of the bed mill the table moves only perpendicular to the spindle’s axis. Whereas the spindle moves parallel to its own axis.

Between these two the turret mills are used more and considered as versatile.

02. Horizontal milling machines

The difference between the vertical and horizontal milling machine is the orientation of spindle axis. In case of the horizontal milling machines, the spindle axis is horizontally oriented.

The horizontal milling machines are suited for the longer or heavy pieces of work. Lots of horizontal milling machines have the rotary table that allows the horizontal milling machine to mill at various angles. This feature is known as the universal table.

are suited for the longer or heavy pieces of work. Lots of horizontal milling machines have the rotary table that allows the horizontal milling machine to mill at various angles. This feature is known as the universal table.

03. Knee type

These machines have fixed spindle and vertically adjustable worktable. It rests on the saddle and is supported by the knee. The knee can be lowered or raised as we have seen earlier. Examples are knee type milling machines includes floor mounted, bench type plain horizontal milling machines.

04. Bed type

In case of the bed type milling machines the worktable is affixed directly to the machine bed. It prevents the workpiece from along Y-axis and Z-axis. The bed type milling machines examples are, simplex, duplex and triplex milling machines. According to their names, simplex has one spindle which moves to either X-axis or Y-axis, whereas the duplex and triplex employs two and three spindle respectively.

05. RAM type

These are affixed to the movable housing ram. It allows the machine column to move alongside XY axes. The examples of bed-type machines include universal horizontal and swivel cutter head milling machines.

06. Planer type

They are kind of same as the bed-type milling machines. They have their worktables fixed along Y-axis and Z-axis. The spindle can be moved along XYZ axes. But the planer type milling machines have the ability to support multiple machine tools.

CNC Milling Machines Working Steps

Just like any part manufacturing starts with the part design, CNC milling process begins with the 2D or 3D CAD part designs. The design completed in the CAD is converted to the CNC-compatible format with the help of CAM software.

Later the CNC program detects the program is stored on the storage of the CNC machines.

- Programs are checked by the programmers and the operators.

- Before running the CNC machine, the operator has to prepare the CNC milling machine.

- The operator fixes the workpiece to the machine work surface or you can say to the work table.

- CNC milling machines are horizontal milling machines and vertical milling machines.

- Depending on the work requirement the required machine with required cutters is selected.

- When the machine is fully prepared the operator loads up the program using the machine interface and executes the milling operation.

Once the program is loaded the CNC milling machine starts to operate the machine. The speed of the CNC milling machine is adjusted via the program itself it about 1000+ RPM and depending upon the process and cuts the work requires.

Generally, with the help of codes in the program the tool is taken near the workpiece. Now, the tool will be fed towards the workpiece with a given depth of cut.

If we compare to the manual milling machine process the CNC milling process feeds the movable workpieces with the rotation of the cutting tool rather than moving against it. So, the basic steps for the milling machine are as follows,

- Design of CAD model, Converting CAD to CNC program

- Preparing the CNC machine

- Loading the program

- Executing the milling operation

Generally, the milling operation is used as the secondary or finishing process. It can produce holes, slots etc. In the milling operation tool will cut the small chips first then the milling operation will go with precision and finishes the part with greater accuracy. The programs are made according to the requirements. So, now let’s check out the types of milling processes.

Types of CNC Milling Machines Operations

01. Plain milling

It is also known as the surface or slab milling. In this operation the cutting tool axis of rotation is parallel to the surface of the workpiece. The plain milling operation uses the plain milling cutters. Wider cutters for larger cutting surfaces and the narrow cutters are used for deeper cuts.

02. Face milling

In case of the face milling the cutting tool axis of rotation is perpendicular to the surface of the workpiece. This process uses the face milling cutters. Generally, the face milling is used to give the flat surfaces or contours for the finished pieces.

03. Angular milling

As the name suggests it is used to produce the angular features to the workpiece. In case of angular milling the axis of rotation of the tool is at some angle to the surface of the workpiece.

04. Form milling

The form milling is used for the milling operations of the irregular surfaces, contours. It uses the forming cutters or fly cutters.

CNC- G and M Codes

The CNC machines are programmable machines. The program is written in the G-codes. The G-codes are specified for each operation of the milling machines. A set of instruction in form of G-codes is used to guide the machines operations. Some examples of G-codes are below,

- G00 – Rapid traverse

- G01 – Linear interpolation

- G28 – Returns to machine axis reference point

- M03/M04 – Spindle start Clockwise/Anticlockwise

- M30 – Program end

Various other codes are also used according to the requirements. But these G codes and M codes are the basic codes used in the CNC milling machines programmes.

Advantages of CNC milling machines

CNC milling machines advantages are,

- CNC machines can work continuously. They can be used 24 hours a day only needed to switch off in case of maintenance.

- The program loaded in the CNC machines can be loaded thousands of times producing the exact same products.

- The software can be updated for up-to-date features.

- The operators require little training and skills compared to manual machine handling operators.

- Only one operator can handle a number of CNC machines, they just need to load the program and they can work themselves.

Disadvantages of CNC machines

CNC milling machines disadvantages are

- They are expensive than manual operated machines. Though the cost is coming down due to the availability of parts.

- The old skilled engineer’s experience is lost considering they are trained on the manual machines for years. But the CNC operator needs only months of training and can operate a number of machines.

- Less workers are required hence they are leading towards unemployment.

- Lack of detailed skills in the operators.

So, these are the advantages and disadvantages of the CNC machines. There are some problems of unemployment but the technology is going to be advanced only. We need to adjust and adapt according to the changing world.

CNC Milling Machines Application

Based on the advantages of the CNC milling machine, a wide variety of design is incurred for various materials. CNC milling machine is used to shape the following materials,

Precious Metals

- Platinum

- Silver

- Monel

- Inconel etc.

Metals

- Titanium

- Iron

- Aluminum

- Carbon steel

- Beryllium

- Copper

- Brass

- Nickel

- Stainless steel, etc.

Plastics

- PVC

- UPVC

- HDPE

- ABS

- Nylon

- Acetal

- Phenolic

- Teflon, etc.

Conclusion

Hence, we have got the basic details of CNC milling machines, along with it’s basic details, types, parts, applications.