Globe valve is explained along with its basics, definition, parts, working principles, diagram, design, advantages, disadvantages, etc. Let’s explore Globe Valve!

What is Globe Valve?

Valve Basics

Before going to the globe valve, let’s try to understand the valve first. As we know, the fluid’s first and foremost property is to flow, and when it comes to regulating, controlling, or directing it, then one of the things that come into play is a valve. Valves can regulate or control a fluid’s flow. They perform those functions by,

- opening,

- closing, or

- partially clogging up the different passageways.

These are mainly the fittings, which have their own set of descriptions. The core word was derived from the Latin word ‘valva,’ which signifies the door’s moving part, and from vovere, which means to turn or roll.

Globe Valve Definition

Here, we are going to discuss the globe valve that is being widely used. A Globe valve holds a prominent place in obstructing or controlling the flow of a fluid.

In layman’s language, a globe valve is a valve that acts on the principle of linear motion, which is used to start, stop, and regulate fluid flow.

- The main part of the globe valve is the disk that can be entirely removed from the flow path or completely restricts.

- It has perpendicular movement to the seat while opening and closing the valve.

The globe valve optimal throttling ability that regulates the flow.

- It occurs due to the disk’s perpendicular movement in which an annular space comes into play between the seat ring and disk.

- The leakage in the globe valve is comparatively lesser than other valves due to the contact between the seat ring and disc at a right angle.

- It allows a tighter seal between the disk and seat.

Function of Globe Valve

- The main functions of these valves are to regulate or start or stop the flow of the fluid.

- These are specifically designed that take control of fluid flow, and the working is not limited to the shut-off capability.

- These attributes differentiate some of the widely used valves, such as gate valves and ball valves.

Why is it called a Globe Valve?

Somehow we wonder why it is called a globe valve?

- The older designs resemble something of a globular structure and can be divided into two main parts: in the shape of hemispheres.

- At this point, the hemispheres are separated by the equator, and here the flow changes the direction.

However, the main internal element in these valves that restricts the flow of fluid is not spherical. Those parts are more like,

- semi-spherical,

- flat, or

- plug shape.

Globe valves are comparatively more restrictive to the flow than other valves, which results in higher pressure drops.

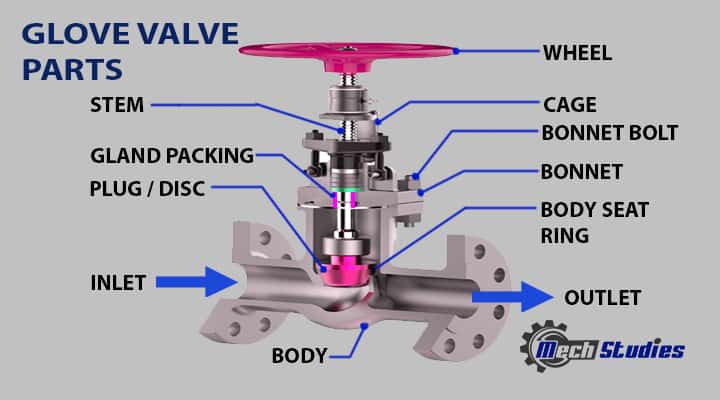

Parts of Globe Valve

There are different parts of the globe valve that help in its core work. Here we are providing a brief description of all of the parts.

Bonnet

The outer part of the valve is known as a bonnet, and it holds the other core parts of the globe valve.

Stem

This part acts as the connector for the disk and valve actuator, which transmits the force explicitly.

Cage

This part of the globe valve surrounds the stem in the valve.

Plug or Disk

The disk is the core part responsible for providing a barrier that blocks or restricts the fluid flow. It moves perpendicular to the seat. When the valve is closed, the disk remains against the seat, which results in plugging the fluid flow, and when it is opened, the disk remains at the top of the seat that helps in passing the liquid.

Globe valve disc is generally three categories,

The ball disk type is used to stop and start fluid flow. Normally, it is widely in low-pressure as well as low-temperature applications. The needle disk type is better than the ball disc type and used for controlling fluid flow. The composition disk type is best for shutoff operation.

- Compression Style Stop Valve Ideal for Stopping, Starting, and Regulating Fluid Flow in Pipelines

- Superior Quality forged Brass Body; Dezincification Resistant; Corrosion Resistant; Lead Free

- Features a Cast Iron Wheel Handle

- ConForms to NSF/ ANSI-61/ 372 Standards; Threaded Ends Comply with ANSI B1.20.1

- 125 PSI WOG

Seat Ring

This part of the valve is essential as it provides all between the bonnet and stem when the disk is rightly pressed. It is tightened with a screw to the valve.

Gland Packing

When the globe valve is in operation, there may be a chance of leakage of the fluid from the valve between stem & body. Here, gland packing is essential which prevents the leakage of the fluid from the stem.

Globe Valve Design

The design of the gloves holds significant importance. There are three major components of the globe valve:

- the disc and stem,

- valve body and seat, and

- the bonnet and packing.

Check a NICE ANIMATED video from saVRee!

The core operation involves the rotation of the threaded stem equipped with a valve actuator or handwheel. The fluid flow passes through the Z Shaped path that helps in meeting at the disc head. The whole process is different from other valves, such as gate valves, etc.

Some of the core functionalities of globe valves also depend upon the design of the sealing element. Numerous globe valves can be open with a low number of turns of the stem that produce a more regulated fluid flow.

However, the plug is also used performs sealing element function which is vital for pistons. Plug being an essential part of the globe valve helps in the globe valve’s effective working mechanism. The design of the globe valve keeps it differentiated from other types of valves.

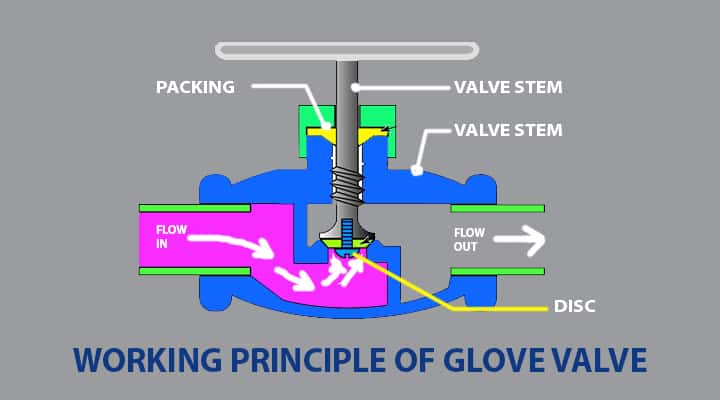

Working Principle of Globe Valve

The core working of globe valves is not that complicated, but there are some of the processes that hold massive importance. The whole valve is controlled by an automatic actuator that helps in regulating the flow of the fluid.

- This regulation of flow is achieved by the perpendicular movement of the disk to the seat.

- Globe valves are capable of controlling the flow automatically or manually.

- The gate valve is situated at a right angle, which restricts the leakage. When the valve is turned clockwise.

- The disk gets lower to the seat that helps in obstructing the fluid path.

- It is also capable of blocking and reducing it entirely.

- This depends on the disk’s position when the valve moves in the opposite direction or counterclockwise, then the disk rises, which in turn helps the liquid to flow without any barrier.

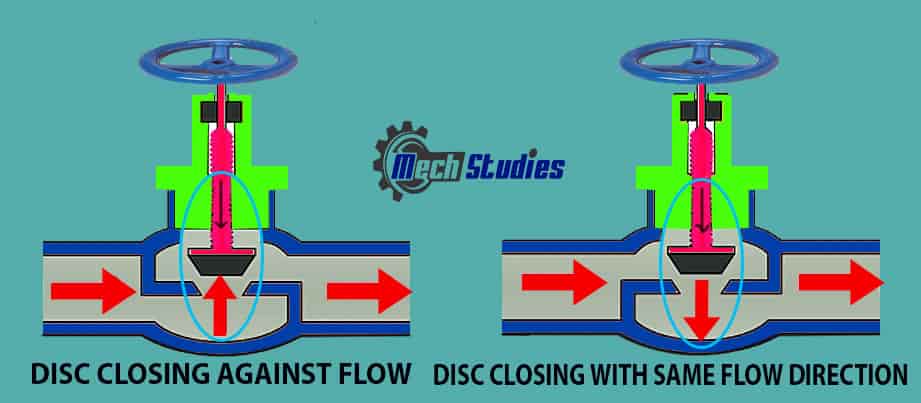

Globe Valve Diagram

Let’s try to look at a globe valve diagram to understand the basic function of the valve. Globe valve has a disc that works based on two scenarios,

- It can close against the flow.

- It can also close with the same flow direction.

Closing against the flow

- In this type of closing, the globe valve disc closes against the fluid flow.

- It is required when a quick start is required.

- Here, the direction of fluid flow is opposite to the disc movement direction.

- The valve is opened to flow the fluid.

Closing with the same flow direction

- In this type of closing, the globe valve disc closes in the same flow direction.

- It is required when a quick stop required.

- Here, the direction of fluid flow is the same as the disc movement direction.

- The valve is closed to restrict the flow of the fluid.

Types of Globe Valve

There are different kinds of globe valves available. Depending on the type of core attributes, the types of globe valve are defined below:

Based on the type of body

Depending on the type of body, globe valve can be classified into three major types:

- Z types Globe valve

- Y types Globe valve

- Angle Types Globe valve

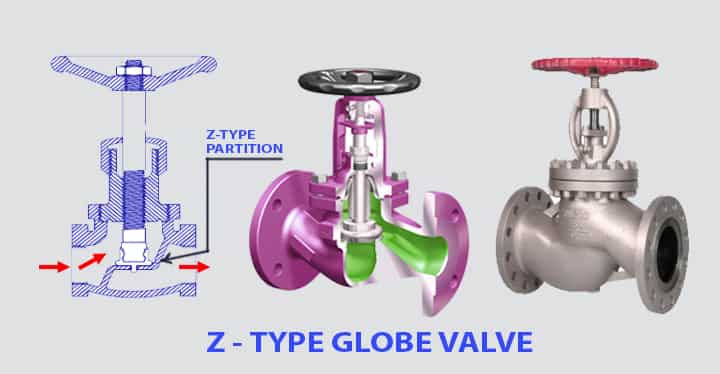

Z types Globe Valve

This is the most common and simple type of globe valve, which is equipped with a simplistic design.

- The seat is available inside, which is surrounded by a Z-shaped partition.

- A horizontal seating arrangement in this type of globe valve helps the disk and stem to travel at a perpendicular angle.

- This kind of mechanism results in an optimally high-pressure loss.

The whole construction of the valve is quite simple. This construction helps the valve seat to be accessible through the bonnet. The design of this valve makes the installation, manufacturing, and repair quite simplistic. This type of Globe valve is widely used in those places where pressure drop is not an issue, and throttling is the basic need.

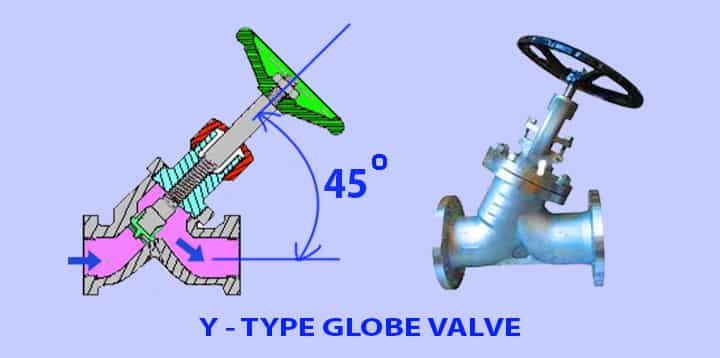

Y types Globe Valve

In those places where there is a problem of the high-pressure drop, the Y Type globe valve provides practical help compared to Z-types.

- The stem and seat are at a 45degree angle to the pipe axis.

- These are capable of delivering useful functionalities in critical services where pressure drop is a major concern.

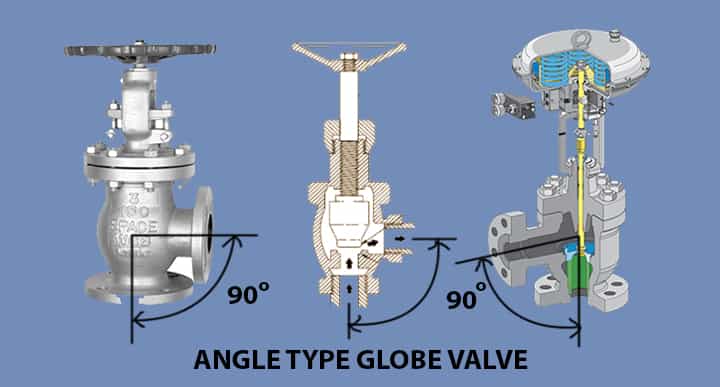

Angle types Globe Valve

These are the most efficient kinds of globe valves that effectively turn the fluid flow direction by 90 degrees.

- It doesn’t need an extra pipe weld or an elbow.

- These kinds of globe valves are useful for those places where there is a need to handle the slugging effect.

Based on body bonnet connection

Globe valves can also be classified based on body bonnet connection. Below is a brief description of some of them:

- Screwed bonnet

- Bolted bonnet

- Welded bonnet

- Pressure seal bonnet

Screwed bonnet

- The screwed bonnets are among the simplest types of globe valve that are available widely.

- These are the kind of valves that are used where inexpensive valves are needed.

Bolted-bonnet

- These are one of the ordinary yet most popular kinds of globe valves.

- The bolted bonnet globe valves’ design is equipped with gaskets that seal the joint between the bonnet and body.

Welded-Bonnet

- For the pipes or joints where the assembly is not required, welded bonnet design globe valves are used.

- These are lightweight as compared to other bolted bonnet design globe valves.

Pressure-Seal Bonnet

- These kinds of valves are widely used for those places that are responsible for high temperature and pressure.

- The pressure seal valves are capable of withstanding greater force due to the higher body cavity pressure.

Application of Globe Valve

Globe valves are widely used for different purposes. Some of the practical applications which are quite important are as follows:

- These are used in those systems where leak tightness and flow control are of foremost concern, such as high point vents and low point drains.

- It can also be used at those places where pressure drop is not an issue, such as lube oil reservoir, feed-water, or chemical containers.

- The abundant usage of globe valves is in power plants, process plants, wastewater plants.

- It is used for regulating and shut off processes.

- Globe valve is used in coolant loops, lubrication systems, steam lines, etc. where regulating the fluid flow is very important and cannot be attained without a valve.

- These valves are used in buildings where there is a need for the upstream fluid flow, such as water heaters and other equipment.

Advantages of Globe Valve

The advantages of a globe valve depend upon the excellent mechanism of the same. The mechanism of regulating the flow through the globe valve massive importance. Here we are providing some of the benefits of using globe valves:

- Globe valves are useful for those places where there is a frequent operation.

- It can withstand wear and tear for a long time.

- Better shut off capacity as compared to the gate valve.

- It is used for throttling fluid flow also in many cases.

- The globe valves are easy to repair as the complicated parts such as the seat and disk can be operated from the valve top.

- Globe valves can provide fast operation compared to other valves due to their shorter stroke length.

- The presence of an automatic actuator makes it quite efficient and simple.

- It can be easily installed in various layout limitations, as globe valve is available with –

- Tee type,

- Angular type,

- WYE type

Disadvantages of Globe Valve

Some disadvantages restrict the productivity of globe valves. Some of them are as follows:

- High head loss is the major disadvantage that comes with a globe valve. It generates due to the discontinuities and obstructions in the fluid flow path. At times this loss generates from different right-angle turns of the flowing fluid inside the valve body.

- There is a high-pressure line, and there are possibilities of impacts and pulsations that can harm the valve’s internal parts.

- Different kinds of globe valves are quite large. These require hefty power to open and also create noise while in operation.

- As compared to other types of valves, globe valves are quite heavier.

- Globe valves are costlier as compared to other valves.

- Power requirements for the operation of valves (opening/closing) are comparatively high.

- Globe valves can seize when not in use for long periods if fluid contains high minerals. In case of closing the valve, the head will jam into build-up and seize closed or almost closed and will detach from the stem upon opening. This is rather common on smaller diameter valves.

Key attributes to look for while choosing a valve

While choosing a valve, it is essential to consider some of the attributes that define the valve’s optimal functions.

Standard

The Standard of the valve defines the quality of the valve. This is among the prominent attributes that help in the selection of valves. There are mainly two standards on which these valves are defined:

- based on the valves market ASME(American) and

- EN(European).

There are some other standards also which depend on where they are manufactured. The standard requirements are specified according to these, and they are made as per fitment.

API 598 – Valve Inspection and Testing

API STD 624 – Type Testing of Rising Stem Valves Equipped with Graphite Packing for Fugitive Emissions

BS 5152 – Cast Iron globe and globe stop and check valves

BS 5352 – Cast and forged steel gate, globe, check and plug valves, screwed and socket welding ends

BS 1873 – Steel globe valves and stop and check valves, flanged and butt welding ends

API 623 – Steel Globe Valves-Flanged and Butt-welding Ends, Bolted Bonnets

MSS SP 80 – Bronze globe valves

MSS SP 61 – Pressure testing of steel valves

MSS SP 25 – Standard marking system for valves, fittings, flanges & unions

MSS SP 45 – Bypass and drain connections

Valve type

The valve type is defined based on the process and the function for which it is going to be used. There are different considerations while choosing the type of valve. This can depend on the need such as

- backflow,

- safety, or

- usage for steam or fluid.

Apart from this, it is also crucial to decide that you need a valve that has seals on both sides or not. When it comes to replacement projects, valve choice only depends on replacing the same type of valve. One can also get adequate information about different kinds of valves from the catalog of the desired manufacturer.

Size of Valve

The size of the valve should be according to the size of the pipe. Globe Valve is widely used for small sizes. Normally, about 10 inches or less, globe valves are used. It’s relatively easy to install. However, some of the factors should be considered while choosing the valve based on size.

- The maximum allowable pressure drop and max flow rate effectively influences the choice of the valves.

- Apart from these two factors, some exceptional attributes should be given preference while choosing the valve.

Pressure Class

While selecting valves or working concerning fluid flow needs, one of the major considerations is pressure. It is vital to give importance to the pressure class of the valve as it is based upon the piping system.

- Defining the right pressure class will make you aware of the pressure needed.

- It’s among the foremost approaches that should be adopted while choosing an efficient valve.

Material

The manufacturing of valves is a delicate process as it is equipped with different parts.

- It is essential to choose the valve’s material wisely as it will be the first layer of safety for critical parts.

- This attribute is the foremost one after the design of the valve.

In addition to these, while choosing the appropriate valve, don’t forget to consider the ambient conditions that play a significant role in the operation. The above fact shows that globe valves are optimally excellent equipment for automation. The construction of these valves depends upon the manufacturer’s discretion as they keep on using different methods.

- Mostly the valves are fitted into a direct-acting stem that comes into play through an actuator.

- A diaphragm or piston makes it quite convincing as the actuator depends on these.

The valve is one of the simplest devices or equipment manufactured as a fluid flow controller. Simply it blocks the path or pipe to manage the flow of fluid. You may found it everywhere at each of the places where the fluid flows in any form. Even it is present in the plumbing system of your house. The core function of the valve is to control the fluidity.

Suppose the valves were not made in this world; think about the consequences you would have gone through. Hefty water bills, no water transportation, and so many scenarios like this where we had to manage things independently. It would have resulted in an inconvenience for everyone. Therefore, the valve is significantly important for our existence.

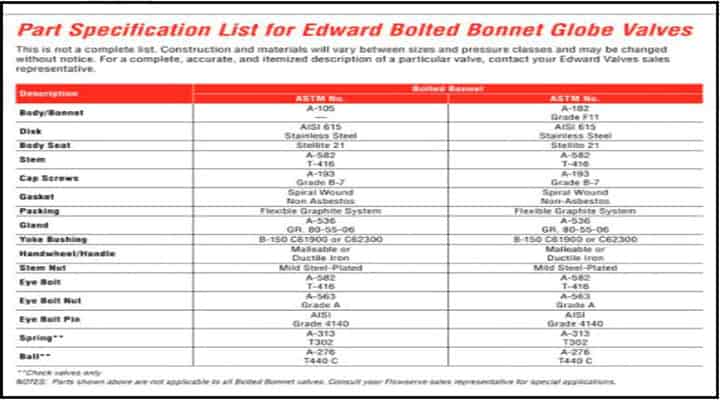

Part Specification List

A standard globe valve part specification list is showing here, for basic understanding,

Summary

This article is all about globe valves. If you want to gain efficient insights about one of the most critical regulatory tools in fluid mechanics, then this article will provide you all. Here you can gain access to the core definitions as well as all the subsidiary information.

The design and working of the globe valve will provide you rooted knowledge about the same. Apart from that, the types, advantages, and disadvantages are the most prominent aspects that help get all-around aspects of the globe valve. Additionally, this excerpt also holds the key areas that should be considered while choosing an efficient valve.