Arc welding is explained along with its basic, definition, how does it works, various machines, different types, uses, advantages, disadvantages, etc. Let’s explore Arc Welding!

What is Arc welding?

Let’s try to understand the arc welding basics along with the definition.

Arc Welding basics

The world is full of improved applications to manufacture and control machines. One of the critical manufacturing processes is Welding. Irrespective of the different types of Welding, as a whole method it is a very significant part of manufacturing products. All the future developments are going to be based on the further gain of productivity in the process of Welding.

- Most probably arc welding is one of the really easy and convenient types of welding processes on the earth.

- Due to its easy process, one needs to gain every kind of information about it.

In this article, you are going to know about arc welding. This excerpt will contain all the basics information related to arc weldings.

Definition of Arc Welding

So, what is the definition of arc welding? Let’s see, Arc welding can be defined as a process of joining two or more materials using the electric Arc for heat.

- The two or more materials can be fused by using the heat produced by an electric arc.

- It is also known as stick welding or manual metal arc welding coined as MMAW.

- It is effortless and easy to understand the process.

- The electric Arc is used to generate heat to a certain amount where it can melt and join metals or materials.

- It is created by connecting a consumable and a non-consumable electrode through a power supply.

Power Supply & Operation

This electric Arc is used with a base material to melt the material at the point of connection. The power supply can come from,

- direct current or (DC) or

- alternating current or (AC)

Depending upon the requirement, the arc welding operation can be,

- manual,

- automated and

- semi-automated by nature.

This arc welding has enhanced the power of fabrication to produce various structures, tools, and vehicles. Since this process of arc welding involves power generated with the help of electricity to form the joints by melting the materials, why is it called electric arc welding?

Arc Welding History

Arc welding was developed in the 19th century, as it became crucial in the process of shipbuilding during the second World war. In the year 1800, Sir Humphrey Davy was known to invent the electric Arc. The electric Arc at this time was produced between two carbon electrodes powered by a separate battery. Since then, the arc welding method acquired an important as well as a popular place in the fabrication industry.

How Does Arc Welding Work?

Let’s check how to weld arc with the working principle as well as basic circuit.

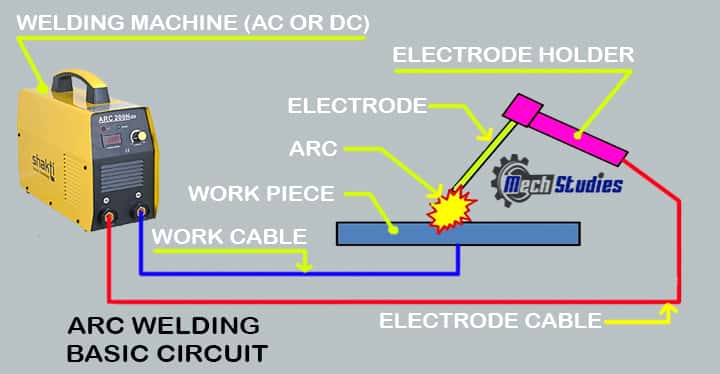

Arc Welding Basic Circuit

Before going to the main working principle, let’s try to understand the arc welding circuit basics. There are main few key things in the basic circuits,

- DC or AC power supply,

- Workpiece,

- Work cable (Work cable means the cable which is connected to workpiece).

- Electrode cable (Since this cable is connected to electrode, it is called electrode cable)

- Welding electrode

Let’s get in the basic circuits, it means,

- The power source (DC or AC) along with suitable control is connected to the workpiece by work cable.

- Another power source (DC or AC) with suitable control will be connected to the electrode holder by electrode cables.

- Due to these connections, the workpiece, as well as electrode, will come in electrical contact if the power source is ON.

- When electrical power is ON, the arc will be generated if the electrode touches the workpiece.

- High temperature produces which helps melts the electrode as well as the base metal.

- Electrode touches the joints, and molten metals or crater formed as well as solidifies.

- This solidification helps to join the metals by making fusion bonds.

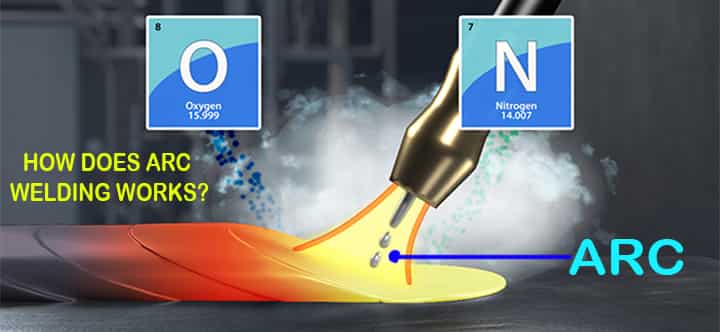

Arc Welding Working Principle

The working principle behind this fusing process to join metals known as arc welding is relatively more straightforward than other types of Welding.

- A certain amount of heat originates from the electric arc strike between the workpiece and the electrode.

- This results in a glowing electrical discharge producing ionized gases among the two electrodes.

- The intense heat of about 6500 degrees Fahrenheit is capable of softening the metal at the point of contact between two workpieces.

The Arc is directed manually or automatically to the line of the join. The electrode is responsible for conducting the current and softening the weld pool while supplying the filler material on the join at the same time.

- When the metals are heated to higher temperatures, the metal workpiece produces a chemical reaction with oxygen and nitrogen present in the air.

- The molten metal is quite dangerous; therefore, to minimize contact with molten metal, protective shielding gas or flux is used in the electric arc welding process.

- After cooling the molten metal is solidified to form the joint.

Equipment Used in Arc Welding Machine

Every process requires some equipment, similarly here is the list of some basic equipment needed to perform the electric arc welding process. There is some equipment used in the arc welding process, which is as follows:

- AC/DC machine

- Electrode holder

- Cables

- Connectors

- Earthing clamps

- Helmet

- Wire brush

- Hand gloves

- Safety goggles

- Sleeves

- Apron

- Chipping hammer

- Electrode

etc.

etc.

Arc Welding Rods

To enhance weld quality, the arc welding process utilises numerous rods of different strong points and weak points.

- The rod is used to conduct the current for the Welding to take place, and it is connected to the welding machine.

- The consumable electrodes general emails and become part of the weld pool.

- It occurs in some cases like SMAW.

- In others such as TAG the rods are non-consumable; therefore, don’t melt.

- There is a wide range of coatings that may vary according to usage.

The uncoated rods are less common and not preferable as it makes it difficult to control the Arc. The quoted rods reduce or eliminate the atmospheric oxidizing components. The coating on the electrode rod can be of three types:

- cellulose,

- minerals, and

- the combination of both.

Irrespective of the layer, the electrode rod can be chosen to create sturdy, clean joints.

Types of Arc Welding

The process of arc welding can be classified into two different segments. These two other segments are consumable and non-consumable electrode processes.

Non-consumable processes

The non-consumable method in arc welding contains welding processes like:

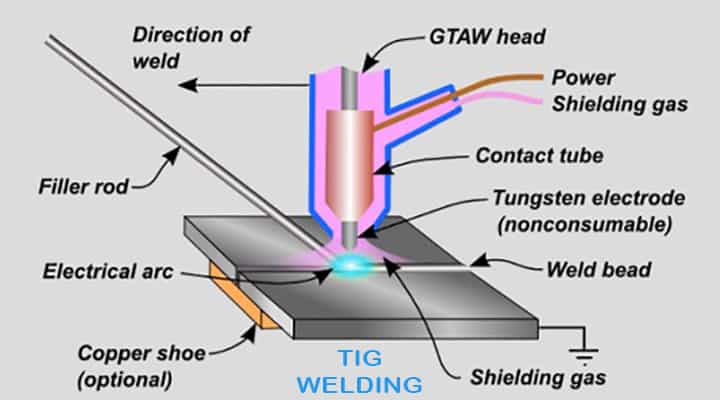

Tungsten inert Gas Welding (TIG)

Tungsten inert gas welding is a welding process that utilises a non-consumable tungsten electrode to produce an arc.

- It is also known as Gas Tungsten Arc Welding.

- The tungsten electrode used in the welding process is incorporated with inert gases like argon, helium etc.

- These inert gases perform the function of guarding the weld pool against atmospheric oxidation.

- It is widely used for thin welding sheets.

Plasma Arc welding (PAW)

Just like TIG, plasma arc welding is also a welding process which involves a non-consumable electrode with an anode to produce an electric Arc placed within the line of join.

- The electric Arc is then utilized to perform ionization in the torch while creating the plasma which will be deposited through a hole in the anode’s base plate.

- Therefore, the plasma is known to perform the function of separation from the shielding gases in this manner.

Consumable electrode processes

In this type of electric arc welding, a consumable electrode is used to produce the joint between two materials at a time as the electrode is consumable, therefore each time, you have to use a new one to create the electric Arc. Based on these features here are the welding processes that come under consumable electrode processes:

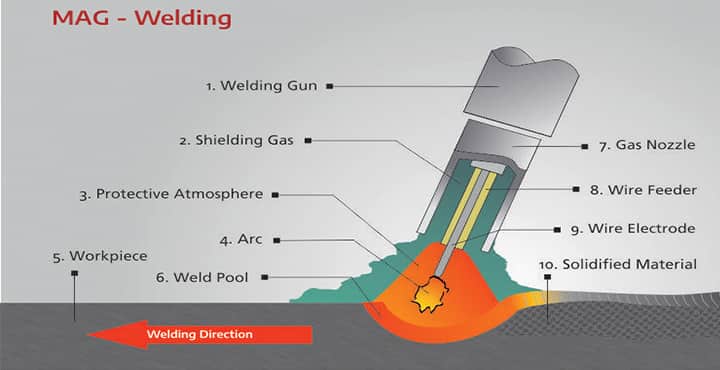

Metal Active Gas welding (MAG)

This is an arc welding process in which the electric Arc originates from a combination of a consumable wire electrode along with the workpiece material.

- Active gases like oxygen, argon and carbon dioxide are used as shielding gases in this process.

- This arc welding process is actively used in steel welding.

Metal inert Gas welding (MIG)

Metal inert gas welding is the arc welding process of joining two or more materials using an electric Arc formed between the combination of a consumable wire electrode and workpiece.

- Just like m a g this process also uses inert shielding gases.

- Argon and helium are two common inert gases that are typically used in this type of Welding.

- It is generally used to weld nonferrous metals like Aluminium.

Shielded Metal Arc welding (SMAW)

Shielded metal arc welding is a welding activity in which the Arc is placed between the electrode flux coated metal rod and workpiece to form a weld pool. Subsequently, when the flux coating of the road melts, then it will produce some gases and slag.

- The gas and slag protect the weld pool from atmospheric oxidation.

- It is a preferable welding process because it is suitable for Welding between ferrous and nonferrous materials with a particular material thickness.

- It is also known as manual metal arc welding, flux shielded arc welding, or stick welding.

Submerged Arc welding (SAW)

It is a frequently used arc welding method in which a consumable electrode with a heap of fusible flux is used to provide a current path between the workpiece and electrode.

- The consumable electrode should be continuously fed, and the fusible flux produces current conduction.

- It is an automatic welding method.

Flux-cored Arc welding (FCAW)

Flux-cored arc welding is alternatively known as SMAW.

- It is a welding process that utilizes a continuously fed consumable flux cored electrode with a constant power supply for providing a consistent Arc length.

- The production of Arc length can either be used as a shielding gas to guard atmospheric oxidation.

Arc stud welding (SW)

This welding process is extensively used to join a nut or fastener with the help of nubs that are responsible for melting the metal for the creation of a joint with another workpiece.

Electro slag welding (ESW)

ESW is a vertical welding process typically used to join thick plates in a single attempt. It is widely dependent upon the electric Arc to start before the addition of flux to extinguish the Arc.

- The consumable wire electrode when it is deposited into the molten pool.

- This molten pool creates slag on the surface of the pool, and the flux enters into a molten state.

- The resistance of molten slag is used to conduct the electric current, which is required to melt the wire and plate edges.

- Then the progression of the process is followed up by water-cooled copper shoes for the prevention from the molten slag to run off.

Application of Arc Welding

The electric arc welding process is commonly used across all the major sectors like,

- automotive,

- oil,

- gas,

- power,

- aerospace

- heavy equipment

- shipbuilding

- aerospace

- construction.

It is significantly used process

- To create,

- To manufacture,

- To repair,

- to modify various tools, machinery, structures, and parts.

Advantages of Arc Welding

When compared with other types of welding processes, arc welding turns out to produce many more advantages than others. Therefore, here is the list of benefits associated with arc welding as follows:

- High-speed processing power: Arc welding is the appropriate use of advanced technology. It is a welding technique that is super quick and performs tasks at a higher speed.

- Higher efficiency: The simplicity of the arc welding process makes it more efficient to use. Even it works on dirty metal.

- Portable in nature: It is readily available across the countries in the world. You can easily carry it with you anywhere. Just a current source is required.

- Produces a powerful joint: It is known for producing a robust joint between the two materials.

- Reliable to use: Arc welding is very reliable for us because of its efficient, affordable and portability factor.

- It is known for performing Welding smoothly even on thick material.

- Gas is not required: The welding process can be completed without carrying the extra load of gases to weld. It can be performed in any atmospheric region.

- Superior welding environment: Often other welding processes require extra effort, whereas arc welding is known to offer a nice atmospheric environment for the welding process.

- Cost-effective: The arc welding process is affordable because of less usage of pieces of equipment.

- Ordinary power source: You can easily use the standard electric power used to perform this type of Welding. The domestic current will be enough to do the process of joining two or more materials.

Disadvantages of Arc Welding

Everything has a negative aspect. Arc welding also has some of the disadvantages, which include:

- The presence of a high expert operator is mandatory to perform arc welding.

- As the electrode covering tends to melt and decrease; therefore, the deposit rate can be incomplete.

- For entire production to take place, one needs to change the electrode periodically as the length of the electrode is 35 mm.

- Reactive metals like titanium and Aluminium will not be preferable as these metals are not clean.

- The efficiency rate of arc welding is a bit low because much waste generation during the process is liable for increased project cost.

- Arc welding will not be used on thin metals of less thickness.

- There may be some welding defects if proper procedures as well as standards are not followed.

Code & Standards for Arc Welding’s

There are many standards available for this types of welding. These are as follows,

| AWS D8.14 | Automotive arc welding (aluminum) |

| AWS D8.8 | Automotive arc welding (steel) |

| AWS D16.1 | Robotic arc welding safety |

| AWS D16.2 | Robotic arc welding system installation |

| AWS D16.3 | Robotic arc welding risk assessment |

| AWS D16.4 | Robotic arc welder operator qualification |

| W48-14 | Filler metals and allied materials for metal arc welding |

| S 499-2C | Welding terms and symbols. European arc welding symbols in chart form in chart form |

| BS 2633 | Specification for Class I arc welding of ferritic steel pipework for carrying fluids |

| BS 2971 | Specification for class II arc welding of carbon steel pipework for carrying fluids |

| ISO 3580 | Covered electrodes for manual arc welding of creep-resisting steels – Code of symbols for identification |

| EN 1011-2 | Welding — Recommendations for welding of metallic materials — Part 2: Arc welding of ferritic steels |

| EN 1011-3 | Welding — Recommendations for welding of metallic materials — Part 3: Arc welding of stainless steels |

| EN 1011-4 | Welding — Recommendations for welding of metallic materials — Part 4: Arc welding of aluminium and aluminium alloys — Part 4: Arc welding of aluminium and aluminium alloys |

Conclusion

These were the information about arc welding. Due to its flexible nature, this welding method is extensively used in manufacturing industries to generate study joints across the world. It can be understood easily but requires skills to perform broadly in different industries. We have enlisted the basic concept behind arc welding, its types, and its usage in the industry. We hope that it might help you in the learning process.