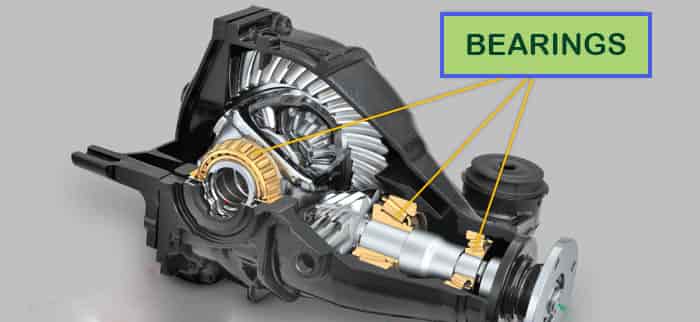

What are bearings? In this article, we are going to learn the basics of bearings like, definition, different parts, types, applications, maintenance tips, causes of failures, etc. Let’s explore!

What are Bearings?

Basics of Bearings

Since evolution, mankind has to rely on its power to pull or push large objects over the earth’s surface. Right from there, the concept of bearings emerges, which makes life easier.

- This concept entails that the force or power helps to lessen the friction between an object and the surface over which it is moved.

- This is as old as mankind itself.

Evaluations of Bearings

The solution to cater to friction first comes as early as 3500B.C in which Mesopwere using one of the first bearings known, which is called a wheel.

- At that time where the axle and wheel touched is equipped with a so-called bearing made up of wood or leather.

- These are lubricated with animal fat.

- There are numerous illustrations and ancient drawings that show different civilization uses this for moving massive rocks for the construction of palaces or their monuments with rollers.

- This is the first known bearing principle that is known to mankind.

- It effectively lessens friction, though it was sliding, not rolling friction.

In the present time, the roller and ball bearings are as same as their predecessors to some extent. With this, we can say that the concept remains the same altogether. Today we have numerous and unimaginable bearings applications, such as in bicycles or different machines where two surfaces are moving or turning against each other.

Apart from these, there are thousands of uses of bearings from a large turbine to a minute internal working of your wristwatch. Here, we will get a proper understanding of the artificial invention that is entirely credible. Without further adieu, let us delve into the core definition of the bearings and then to other parts.

Definition and Meaning of Bearings

Bearings Definition

When it comes to defining bearings, the functionalities are the best approach that helps in understanding the core meaning. One of the descriptions entails that,

”Bearing is a device used to guide and support an oscillating, rotating, pivot, sliding shaft, or any wheel.” – This is simply bearings definition.

The need forbearing in any of those is for the smooth and effective operation of the attached part.

What Does Bearing Mean?

Furthermore, we can further develop bearings definition and understood that the bearing can be effectively defined based on functionalities. The following are the three main functionalities of bearings through which we can understand effectively:

- To decrease friction

- For supporting a load

- For guiding moving parts such as pivots, shafts, and wheel

These are the three main functions of bearings. Let’s get into these functions in brief.

Function of Bearings

To decrease friction: On this basis, the bearing can be defined as that part that keeps the shaft moving smoothly and consistently while decreasing friction.

- For this usage, bearings is used in several industrial applications, automotive as well as fleet.

- This is one of the most prominent functions of the bearings.

For supporting a load: The bearing contains the property through which it cans effectively decrease the energy and effort needed to move or slide an object over the surface. This functionality of bearing is among the common ones yet of great importance.

For supporting a load: The bearings are the effective materials present in the shaft in which the shaft readily pushes the bearing in the same direction in which there is a moving load.

- The core factors on which the loads rely are dependent upon both direction and weight.

- In this case, if we will use the wrong kind of bearing, then we may not carry the needed load.

When it comes to supporting a load, then there are three kinds of loads that need bearings. Radial load is the load in which the load pushes down on the bearing.

- The direction of the load is at right angles to the shaft.

- Apart from this, the thrust load occurs when the direction of the load is parallel to the shaft.

- In this, the load pushes down on the bearing.

- In the angular load, the load pushes down sideways on the bearing.

- It is a combination of thrust and radial load.

Parts of Bearing with Definition

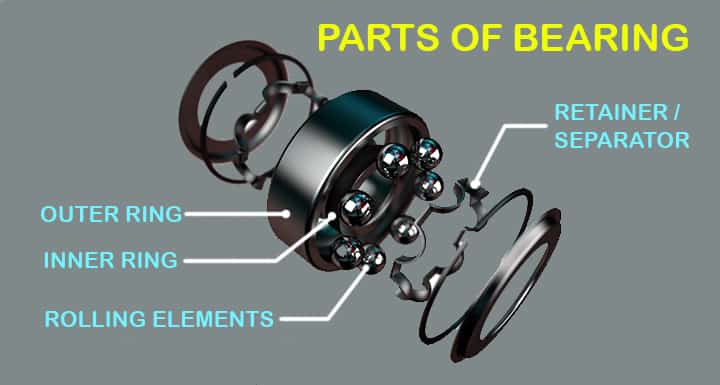

When it comes to the different components of bearings, four prominent parts ensure legless and smooth performance.

The following are those:

- The outer ring or outer race

- Inner ring or inner race

- Rolling elements

- Retainer or separator

The outer ring or outer race

This is the bearings exterior ring, and the core functionality of this component is to protect the internal parts of the bearing. For this, it has to be machined with accurate and smooth touch.

Inner race

The inner race is the component of the bearing that effectively situates directly on the shaft.

Outer race

This is the outer ring of the bearing that contains the rolling balls. These balls help the bearing to move smoothly. The practical shape of the rolling elements critically depends upon the load that is going to lie on the bearing. It also depends on the multiple applications.

Separator

The separator is a metal retainer that effectively holds the rollers and balls. The separator is positioned in between the outer, and inner races. The core function of the separator keeps the rolling elements in an even-spaced setting.

Types of Bearings with Definition & Core Applications

Just understanding the different kinds of the bearing will not get us to grab all the insights fully. To cater to this, we are here to provide some of the different kinds of bearings with their critical applications in daily life. When it comes to types of bearings, the following are the typical kinds of bearings:

Ball bearings

Ball bearings are the most common kind of bearing that has wide usage. It is capable of handling radial as well as thrust loads. Though it can only handle a sheer amount of weight. Furthermore, this ball bearing is classified into different kinds, such as,

- Angular contact ball bearings

- Deep groove ball bearing

- Self-aligning ball bearings

Angular Contact Ball Bearing

Angular contact ball bearings are capable of withstanding high radial-axis loads. Apart from this it also enables to reach high speeds.

- These are pretty inaccurate for manufacturing reasons as they can only withstand unidirectional loads.

- These are mounted explicitly in numerous groups that provide efficient results.

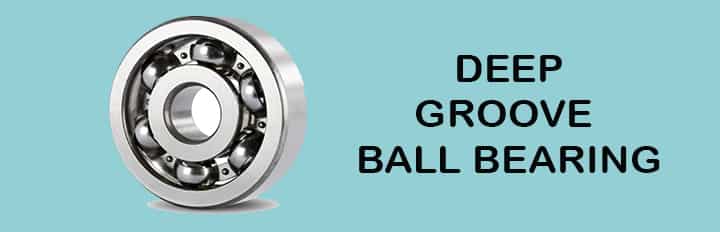

Deep Groove Ball Bearing

Deep groove ball bearing is among the most widely used roller bearing due to its optimal performance and versatility.

- They are equipped with deep raceway grooves in which the inner and outer tings are equipped with circular arcs.

- It is also equipped with lock rings that provide maximum efficiency.

Self-aligning Ball Bearings

Self-aligning ball bearings are equipped with an inner ring that also has two raceways.

We can quickly correct misalignment that is effectively caused by shaft machining or housing machining, or wrong installation.

Thrust Ball Bearings

Thrust ball bearings are the bearings that are designed to cater to a high axial load parallel to the shaft.

- This bearing needs higher oil lubrication.

- It is composed of two washers which are combined the rolling elements.

- In this, the ball thrust bearings can be operated at much higher speeds at lower loads.

Thrust bearings are effectively used in,

- automotive,

- marine, and

- aerospace applications

.

.

These are also used in,

- primary and tail rotor blade grips of RC helicopters,

- forward gears in modern car gearboxes,

- radio antenna masts, and many more.

The application of this type of bearings is basically in household items such as,

- Sewing Machines,

- Washing Machines,

- Tumble Driers,

- Bicycles,

- Skateboards,

- Hair Dryers,

- DVD Players, and

- Fishing Rods.

Apart from this, it can also be used in equipment and industries such as,

- Hard-Drives,

- Fans,

- Air-Conditioners,

- Photocopier,

- Fax Machines,

- High-speed Machine Tooling Equipment,

- Paper Making Machinery,

- Chain Saws,

- Assembly Lines,

- Escalators,

- Medical and Dental Equipment.

Last but not least, it can also be used in automotive such as,

- Electric Motors,

- Gear Boxes,

- Transmissions,

- Steering,

- Driveshaft,

- engines, and

- Driveline.

Roller bearings

This is also among the prominent kind of bearings that are used widely. The roller bearings have vivid types which are based on their structure and load capacity. The following are some of the types of roller bearings with their description and their core applications.

- Spherical roller bearings

- Tapered Roller Bearings

- Cylindrical Roller Bearings

- Needle Roller Bearings

- Thrust Ball Bearings

Spherical roller bearings

Spherical roller bearings are a rolling-element bearing that helps in the rotation of the machine with low friction.

- It also prevents angular misalignment.

- Despite the name of this bearing, these are not spherical.

- The rolling element is the spherical roller bearings are mainly in the shape of a cylinder, but the profile makes it seem like an inflated cylindrical shape.

The core applications of this kind of bearings are in,

- mining and construction equipment,

- pulp and paper processing equipment,

- marine propulsion,

- Gearboxes,

- wind turbines,

- continuous casting machines,

- material handling,

- pumps,

- mechanical fans, and

- blowers.

Tapered Roller Bearings

Tapered roller bearings are a roller bearing that allows the bearings to effectively control radial and thrust loads with its tapered angle projection.

With this, we can get an accurate rolling motion of the rollers towards the raceways. The core applications of this roller bearing are in,

- sports robot combat,

- axle systems,

- gearbox,

- engine motors and reducers,

- propeller shaft,

- Agriculture,

- construction and mining equipment,

- railroad axle-box,

- differential,

- wind turbines, etc.

Cylindrical Roller Bearings

Wherever there is a need to carry heavy loads, we use cylindrical roller bearings.

- The core rolling element is a cylinder that effectively means the load is distributed over a larger area.

- This enables the bearing to withstand a more significant amount of weight.

The core applications of this roller bearing are in,

- construction equipment,

- crushers,

- electric motors,

- blowers and fans,

- gears and drives,

- plastics machinery,

- Briquetting machines,

- rubber mixing equipment,

- rolling mills,

- rotary dryers,

- pulp and paper machinery,

- petroleum production,

- power generation,

- power transmission,

- cement processing,

- machine tools and traction motors,

- pumps.

Needle Roller Bearings

These are special roller bearings that effectively use thin, long cylindrical rollers that look like needles.

Needle bearings have rollers that are four times longer than their diameter. The prominent applications of needle roller bearings are in,

- automobile components such as two and four-stroke engines, planetary gear sets,

- rocker arm pivots,

- pumps,

- gearboxes,

- automotive power transmission systems, and

- air compressors.

Slewing Bearings

A slewing bearing is a rotational rolling element that is specifically able to cater to the heavy load.

- Though these are slow oscillating and can be used, there is minimal use of speed for the material movement.

- The manufacturing of slewing bearings is with gear teeth integral used to operate the platform in respect to the base.

The core application of slewing bearings is in different sectors such as construction, medical, and many more.

In the construction area, it is being used in,

- Cranes for Bulk handling,

- shocks vibration,

- handling container

- Rubber tyre – gantry crane & Reach Stackers,

- Concrete Pumps, and

- Mixers.

When it comes to usage in the medical field, this is used in,

- Radiotherapy applications,

- pharmaceutical industry for all production steps,

- mixing,

- filling,

- cleaning, etc.

Apart from that, it can also be used in,

- Forest Industries,

- Radar Military,

- Man lifts in Firetrucks, etc.

Plain Bearings

After understanding Slewing Bearings’ definition, let’s delve into plain bearings. This is one of the kinds of bearings that are pretty simple and is equipped with only a bearing surface with no rolling elements.

- These are capable of high load carrying capacity and also relatively inexpensive.

- The lower cost associated with this kind of bearing makes it quite effective.

The application of plain bearings is in,

- compressors operating in critical pipeline applications,

- ship propeller shafts,

- turbo pieces of machinery, etc.

Signs of Bearing Damage

Bearings are typically manufactured for last longing usage, though the life expectancy of these bearings can be deduced based on metal fatigue and the kind of load. We can also get an understanding of that through the general conditions.

- Bearings mainly get into premature failures which are free from metal fatigue.

- There are numerous causes of this, such as incorrect mounting, minimal lubrication, poor condition of shaft, and many more.

Premature failures can be avoided by getting an account of different signs of being damaged. This part of this article will provide an overview about the same with their causes and preventive measures:

- Brinelling

This is the damage, and mainly the indentations pressed into the bearing race; though they are not visible to the naked eye, these can cause serious, deeper dents that are the ultimate cause of bearing failure.

The cause of brinelling is excessive pressure against the unmounted race during installation. Apart from that, it can also be caused by hammering the bearing during the removal or installation of the race. It can also be caused by impact during operation.

The prevention of brinelling is by exerting pressure on the press-fit race. This is only applicable when the brinelling is caused by incorrect mounting. Eliminate the possibility of hammering his bearing while installation can save us from this damage.

- Fretting

Fretting is the damage in bearing that refers to small metal particles, decay or break off the bearing races. It occurs when there is extra contact between the inner race and the shaft or the outer race and the housing. In a way, we can be sure that fretting occurs when any surface gets over-stressed under excessive load.

The primary reason for fretting is the excessive friction that causes metal parts to break off the bearing race or ring. It is also caused by housing fits or poor shaft.

We can prevent fretting by keeping a check on shaft and housing fits before using them. With the help of special lubricants and micronized graphite, one can also reduce the rubbing pressure, thus diminishing the possibility of fretting.

- Peeling

Peeling refers to a light scraping of the surface from the bearings. However, the damage is minimal, so it does not affect the bearing performance at large, though it should be kept under a magnitude so that it does not get on to cause more significant damage.

The prominent cause of peeling is related explicitly to minimal lubrication. If we do not lubricate the bearing enough, then t may cause this problem. It is pretty essential to use high viscosity lubricant that keeps the peeling away from the bearings.

To cater to this damage, it is prescribed to check lubrication levels in the bearing so that there is an ample amount of lubricant present all along. While lubrication, it is recommended to force grease around the cage, races, and rollers.

- Contamination

Contamination of the bearing entails the pitting, soring, and scratches along the raceways. This defect also marks scratches and pitting on the ball and roller surfaces. In this defect, the small indentations are pretty more and scattered.

The leading cause of this is the defective seals or shields due to the accumulation of dirt, dust, or abrasive particles on the bearing surface.

- It can also be caused by improper cleaning of the shaft as well as housing.

- If one is using dirty tools or hands while mounting and assembles then also this defect is prone.

To prevent this, the prominent solution is to use everything clean while getting in contact with the bearing, whether it is the area or hands, or tools. While lubricating, it also essential to get an effective dirt-free area and container that keeps the dirt and dust away.

- Electric arcing

There are numerous machines in which the bearing has to withstand the electric charge. Electric current can easily damage a bearing. Even a tiny amount of voltage passing through a bearing can burn a pit onto the ring point of contact.

- The leading cause of electric arcing in the bearing is the current passing.

- This can occur when there is welding on a vehicle without adequate grounding and causes arcing and burning.

- This can cause a single burn spot which also has the audacity of bearing failure.

The preventive measures that can keep electric arcing at bay are proper grounding. The bearing for checking any stray current not to pass through the races of bearings is the core inspection of the bearing. The other causes of bearing failures are,

- Improper mounting

- Fatigue

- Excessive loads

- Failure due to lack of lubrication

Maintenance of Bearings

After selecting, assembling, mounting, adjusting, and lubricating bearings, now it comes to the proper maintenance of the bearings, the maintenance of the bearings keeps it away from major failures. When it comes to the right way of maintenance, there are somehow specified ways to help effectively. The maintenance procedure includes:

- Regular inspection of the bearing, shaft, and housing for damage

- Keeping a check on mounting and assembly

- Lubrication schedule at defined intervals

- Necessary adjustment

- Cleaning the bearing

Regular inspection is the process in which the inspection is scheduled on a defined basis. Most of the manufacturers provide a specified schedule of inspection.

- This includes checking for the supposed defect that can affect bearing, such as grooves, nicks, and polished surface on the housing, rust spots, and numerous others.

- A regular and straightforward inspection provides valuable insights that can prevent bearing damages.

Keeping a check on mounting and assembly refers to the critical inspection of the adjustments made during installation. This one should keep a comparison schedule as per their installation process and the one provided by the manufacturer.

- Apart from that, one of the basics is checking the lubrication.

- This keeps the excess heat, friction, and level of corrosion at bay, thus reducing the probability of bearing failure.

- Furthermore, it is also important not to exceed the lubrication levels and use the lube specified for the job.

Finally, while inspection t is quite essential to clean or replace the parts when necessary, it is also prescribed to replace the components as per the manufacturer’s recommendations. The above is a brief description of the proper maintenance of bearings to keep the damage or failures at bay. Though it can be more detailed, that can help us to understand more effectively.

Conclusion

With the overall understanding of the bearings, one can get hands-on knowledge about the same. This article is equipped with all the related information that is quite vital for the understanding of bearings. In this, we have discussed the core description with their components and different kinds.

The applications of the same are also discussed elaborately, which makes it quite effective. Apart from all of this, we have also made a good idea about the different kinds of problems occurring in bearings and their solution. These solutions will help us to overcome effectively. However, there are lots to discuss bearings that have their importance which can be discussed further. Any questions on bearings definition?

Hi, There’s no doubt that your blog may be having browser compatibility issues. Whenever I take a look at your site in Safari, it looks fine however when opening in I.E., it’s got some overlapping issues. I simply wanted to give you a quick heads up! Aside from that, great website!

Hello,

Thanks for the information about the issues, we will look into it.

I seriously love your website.. Excellent colors & theme. Did you build this web site yourself? Please reply back as I’m hoping to create my very own website and would love to know where you got this from or what the theme is called. Thank you!

Income school, ACABADO Theme