Hi Friends, do you have any idea about the different parts of a car engine, its diagram or have you seen a car engine, and what it looks like? If you have a car or not, it is mandatory to know all the parts of a car engine. The diagram of engine part is also mandatory to understand the proper position of the same in engine, how it looks, function etc. Let us learn in detail. In this article, we will learn all parts of a car engine along with the basic details, functions, etc. with a simple explanation & diagram.

Car Engine Parts & Diagram: Basic Overview

The car engine has various components and together all components it completes its process to drive the car. The engine block is the main base of a car’s engine which houses all parts like the piston, piston rod, piston ring, crankshaft, and many more.

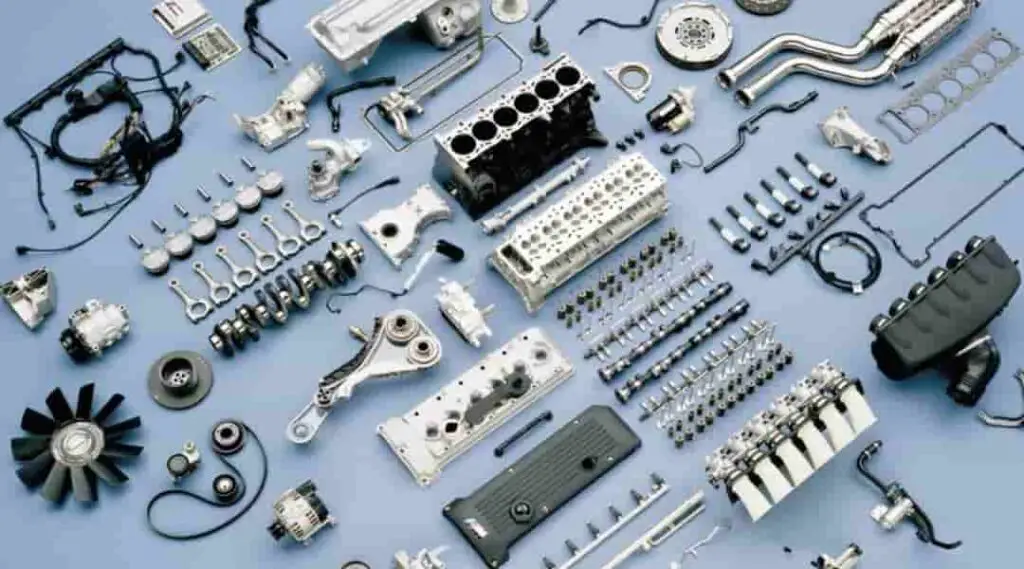

Normally a car engine has more than 150 parts for an internal combustion engine and a few of them which are of utmost importance have been captured here.

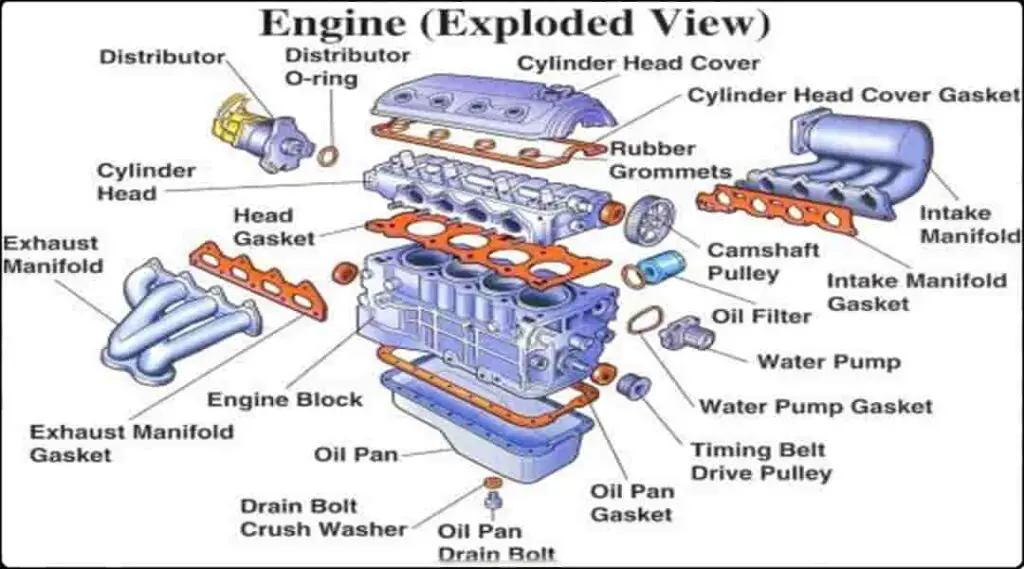

Car Engine Parts with Diagram

Let us see a simple car parts diagram including all the main parts which are essential to know. Refer to the below car parts diagram so that we can understand the exact location of each one and how it looks.

Car Engine Parts Name

| Engine Block | Jacket for water absorption |

| Piston | The radiator of the car |

| Piston Rod | Upper tank |

| Piston Ring | Lower tank |

| Crankcase or Oil Pan | Radiator cores |

| Rotor | Radiator Fin |

| Housing | Hoses of radiator |

| Inlet & Exhaust Port | Input radiator hoses |

| Spark Plug | Outlet radiator hose |

| Spark Plug Wire | Divider radiator hose |

| Output Shaft | Cap of a radiator |

| Cylinder Liner | The thermostat of a car |

| Cylinder Block | The output shaft of a car engine |

| Cylinder | Crank case of an engine |

| Crankshaft | Traction battery pack in a car engine |

| Ignition Switch | Water circulating pump |

| Ignition Coil | Air Box of a car engine |

| Deck | Engine power control unit |

| Oil Passage | Cooling water reservoirs |

| Camshaft | The thermometer of a car |

| Cams in a camshaft | Waste-gate Valve |

| Camshaft Bearings | Indicator in the dashboard |

| Bearing journals in the camshaft | Carburetor |

| Bearing Shells | Carburetor adjustment tool |

| Distributor | Engine Valve |

| Track Follower in a camshaft: | Check Valve |

| Lobes of camshafts | Bimetallic engine valves |

| Sprockets of the chain | Monometallic engine valves |

| Ends | Hollow Engine Valves |

| Woodruff key in camshaft | Induction Motor |

| Centrifugal Advancer | Intercooler |

| Vacuum Advancer | Car battery |

| Thrust Plate in camshaft | Car starter Switch |

| Engine cooling system | Engine mount guard |

Car Engine Parts Description, Function & Diagram or Photos

1. Engine Block

Within an internal combustion engine, an engine block contains the cylinders, as well as other components. Early automotive engines had nothing but a cylinder block attached to a separate crankcase. The crankcase and cylinder block are typically integrated into modern engine blocks. In addition to coolant passages and oil galleries, engine blocks often include other elements.

2. Piston

Power is produced by the combustion process of the piston, which is the heart of the engine. From the crankshaft, the flywheel, the power transfer and drive wheel, the piston that moves up and down generates energy. In addition to the flat and convex piston heads, there are several other shapes as well.

3. Piston Rod

As the main connecting rod between the crankshaft and piston, the piston rod plays a vital role in the engine’s operation. As the piston releases power, the piston rod converts that energy into rotational motion.

4. Piston Ring

Despite being invisible, piston rings play an important role. Piston rings prevent leakage during compression by sealing the piston with the cylinder block. Oil entering the combustion chamber and gases leaking during compression can cause problems for the overall engine. Additionally, the piston ring reduces oil build-up on the cylinder walls.

5. Crankcase or Oil Pan

Crankcases are essential to an engine’s performance. An engine’s crankcase or oil pan acts as a reservoir for engine oil, which lubricates all engine parts. A bolt and gasket prevent oil leakage from the crankcase, located beneath the cylinder block. The crankcase has an oil plug or drain plug.

6. Rotor

The three corners of the rotor seal the combustion chamber from the outside. Additionally, one side of the rotor has internal gear teeth. The gear teeth enable the rotor to revolve around a fixed shaft. There is an inlet or pocket on every face of the rotor, which is installed to allow a greater volume of gas to be injected, thus increasing the displacement rate. At the center of the housing, you will find gears that are attached to the shaft that move the rotor. As a result of those two shafts, the sides are kept in touch with each other so that three combustion pockets remain separate.

7. Housing

A rotor engine is incomplete without a housing, which is an important component. The rotor is designed in an epitrochoid shape, also known as an oval shape, such that the tips are always in contact with the chamber walls. The housing is cleverly outlined as the three tips or corners of the rotor continuously remain in contact with the housing. The intake and exhaust ports are one of the key components which are found within the housing. It is extremely important since each part of the housing completes one of the combustion processes, such as Intake, Compression, Combustion, and Exhaust.

8. Inlet & Exhaust Port

New blends enter the combustion chamber through the intake port, while exhaust gases leave the combustion chamber through the exhaust port. There are intake and exhaust ports in the housing; however, these ports do not contain any kind of valves. There is a direct connection between the exhaust port and the exhaust, while the intake port connects directly to the throttle.

9. Spark Plug

A spark plug sends an electrical current to the combustion chamber, which ignites the fuel-air mixture and causes the gas to expand abruptly. A spark plug completes the ignition system of a gasoline engine. As the receiver of electric current from the output coil, the spark plug is composed of a core or electrode rod and a ground located within the body. An electrode tip has a positive electric charge, while the ground has a negative charge, thus the gap on the spark plug. A spark occurs when electricity exits or jumps to the ground from an electrode if it has a high voltage. Fire is produced by spark plugs in this way.

10. Spark Plug Wire

Spark plug cables differ in shape and capability from common cables. Copper cables with thick insulators are usually made of large diameters. In this case, the spark plug wires will connect the super-high voltage produced by the output secondary coil to the spark plug. Therefore, it is necessary to use a cable with a high level of endurance.

11. Output Shaft

Eccentric cams are mounted on the output shaft; they are offset from the centerline of the shaft. The rotor does not spin in, so you need these eccentric cams for just the shaft rotation.

12. Cylinder Liner

Among the features of a wet liner cylinder block is that its walls may be removed, and they fit in the block using special gaskets. Wet liners are that type of liner that is in direct contact with the engine’s coolant. That is, the liner is entirely of one piece, rather than merely a sleeve.

13. Cylinder Block

Cylinder blocks are structures that contain the cylinder and related components, such as cylinder sleeves and coolant passages. During the early development of internal combustion engines, cylinders were often cast individually. Cylinder blocks were often made separately for each cylinder.

14. Cylinder

There are spaces around pistons where they travel. There are large holes forming a seal alongside the piston and are of precise shape. Considering the size and number of cylinders of an engine, we can determine its power and size.

15. Crankshaft

This component is found at the bottom of modern engine blocks, where the crankshaft is housed. There are other components, such as engine mounts, core plugs, coolant, and other mountings and ancillary components.

16. Ignition Switch

Through the ignition switch, the positive pole of the battery is connected to the primary winding of the ignition coil, while the negative pole is grounded. Using this switch key, the ignition system can be turned on and off.

17. Ignition Coil

It acts as a step-up transformer, or raises the battery voltage; this is the most important component. In addition to using two coils to operate, this coil works on the principle of electromagnetic induction. In a secondary coil that has more coils than a primary coil, the voltage can increase when magnetism from the primary coil is absorbed by the secondary coil.

18. Deck

There is a cylinder head on the top surface of the block.

19. Oil Passage

Combined with cylinder heads and crankshafts, these allow oil to be transported to them.

20. Camshaft

A camshaft can be characterized as a device that converts rotary motion into linear motion and vice versa. In order to achieve a specific displacement, the cam on the camshaft engages in a radial turning pattern, while the follower follows the axis of rotation vertically so that the displacement is achieved. According to the design of the engine, the camshaft’s position varies depending on how it’s mounted

21. Cams in a camshaft

Cams are devices that are designed to transfer the movements required to the followers through direct contact with the cam. There are multiple cams installed on each engine’s camshaft, each of which has its own motor, and in order to install the cam, the valves must be installed first.

22. Camshaft Bearings

A camshaft bearing can be considered one of the most important parts of a camshaft as they are responsible for holding the shafts in the correct position and are also responsible for reducing friction during camshaft operations. There is also an oil inlet on the camshaft which ensures that the oil in the camshaft is always changed in a continuous manner.

23. Bearing journals in the camshaft

There are two types of bearing journals, one that is present in close contact with the followers while the other is a part that rotates on the camshaft. It is a device that transforms the rotatory movements into linear movements by turning them into circular motions.

24. Track Follower in a camshaft:

As the name implies, a track follower is nothing more than a roller or a needle bearing that follows the cam love profile in order to operate, and it is also known as a cam follower. A cam follower can be configured in a number of different ways, but the most important feature is the way in which it is attached to the mating part, which is responsible for the rotation of the cam follower. A yoke cam follower features a hole in its center, whereas a stud cam follower uses a stud as its mounting point instead of a hole.

25. Lobes of camshafts

In order to make the piston move with the camshaft, the lobes rotate with the camshaft. Essentially, the purpose of the lobes of a camshaft is to open and close the valve which allows air to enter and leave the engine. Depending on the speed of the car’s engine, the operation of the lobes directly depends on how fast the engine is going.

26. Bearing Shells

In general, the bearing journals are scaled with a bearing shell that sits on the top of the journal. Bearing shells serve the purpose of smoothing the rotation of a camshaft and protecting the engine against being damaged or shattered in case of an engine failure, by preventing wear and tear of the bearing shell during rotation.

27. Distributor

Distributors are used in conventional ignition systems to determine timing and firing order. An assembly of shafts and cams is used in the distributor to disconnect the primary coil flow.

Meanwhile, you will find two major components of the fairing order at the close of the distributor: the distributor cap and rotor. Rotors are conductors that distribute coil output to spark plugs, while distributor caps channel and receive coil output to the rotor from the spark plug wire.

28. Sprockets of the chain

An engine’s timing belt is attached to a chain sprocket at the end of the camshaft for the purpose of retaining it. This sprocket is connected to a chain by means of a pawl. There is no need to touch these sprockets so that they will be able to turn at the same speed even if they are not in contact.

29. Ends

A belt is designed to be attached to the front end of the cam so that it can be connected to the crankshaft by the belt. In order to operate the engine, the rear end of the camshaft is connected to a special gear that turns the distributor. This part is in a position to match the ignition timing of the rest of the engine with the rest of the ignition system.

30. Woodruff key in camshaft

Among the most crucial components of a camshaft is the woodruff key, which is one of its most important parts. In addition to its other purposes, it also serves to ensure that the camshafts move at the desired timings, among its other functions.

31. Centrifugal Advancer

Similar to vacuum advancers, centrifugal advancers change the ignition timing of engines based on their RPM. To prevent knocking and self-ignition, ignition timing must be made earlier when the engine is working at high RPM. Centrifugal Advancers use two weight ballasts that stretch as a result of centrifugal force. To accelerate the platinum open angle, this ballast will be attached to the distributor shaft, giving rise to the centrifugal force in the ballast.

32. Vacuum Advancer

A vacuum advancer is used to advance the spark or change ignition timing. The aim is to adjust the condition of the engine with ignition, for example when the engine is carrying a heavy load. Even when the valve is fully open, this condition will cause slow piston movement.

As long as timming remains, it could only inhibit piston rate if the contra effect remains. Approximately 0 degrees of ignition timing will be reversed to maximize combustion expansion for piston compression. By sensing the vacuum in the intake manifold, the vacuum advancer reverses the ignition based on engine load. Suction power on the piston decreases when the conditions above are met, and the contact point shifts more slowly.

33. Thrust Plate in camshaft

It is necessary to have a thrust plate for the rear cam to provide support, and it is mounted up the front cover of the engine and it attaches to the cam between the rear gear and the cam itself.

34. Engine cooling system

The engine cooling system of a vehicle ensures not only that the engine stays cool, but that it’s also kept heated enough for efficient, clean operation. Heat is generated by the explosions that occur within the internal combustion chamber, the cooling system plays a crucial role in this. Temperature in the engine is regulated by the components of the cooling system.

35. Jacket for water absorption

As the name implies, a water shell serves the purpose of absorbing the heat that is generated by the engine evenly and more commonly as a water jacket. The term “water jacket” simply refers to the water channel that is present around the engine, and it is referred to as the water jacket.

36. The radiator of the car

Coolants are cooled by radiators, which are iron-shaped components that are used to cool coolants. Radiators work by moving the temperature from water to free air, and that is the basic principle behind how they work. In the process of cooling coolants, radiators are components that are iron shaped and are used to distribute heat to them in order to cool them. Here’s what the mechanism is, the hot coolant will be channelled to the core of the radiator and it will be cooled by the coolant.

Due to the fact that both steel and aluminum are conductors of heat, the heat will move from here to the core radiator as well as directly to the radiator fins. Heat will move into the airflow when there is air flowing through the fins as there is air flowing through them.

37. Upper tank

As the name suggests, it is the upper tank that is used to hold the hot water or coolant that comes from the engine.

38. Lower tank

This is the main purpose of the lower tank to store and transport the cooled coolant back to the engine after it has been cooled.

39. Radiator cores

It is rectangular channels that connect the upper tank and lower tank spaces using a flat channel. In order to determine the cooling power that a radiator is capable of, it is necessary to have the right number of cores.

40. Radiator Fin

There are several cores on the surface of the radiator which are connected by a thin zinc fin. A fin is used to take heat from a core and release it into the air passing through it while at the same time receiving heat from the core.

41. Hoses of radiator

A radiator hose is a hose that serves the purpose of supplying radiator coolant from the engine directly to the radiator and then back to the engine again. The purpose of this part may only be to channel the coolant, but the importance of this part cannot be overstated any longer.

42. Input radiator hoses

It is a radiator pipe whose purpose is to convey high-temperature coolant from an engine to the radiator.

43. Outlet radiator hose

It is a radiator outlet hose that is responsible for carrying low-temperature coolant to the water jacket on the engine, which is then supplied back to the radiator to maintain a constant temperature.

44. Divider radiator hose

This hose can then be used to handily divide fluid from one component to another by passing it through the divider hose.

45. Cap of a radiator

During the operation of the cooling system, the radiator cap serves as a cover for the upper tank radiator and keeps the air pressure within the system under control. The design of this lid is different from that of a bottle cap or other lid because inside this lid there is a pressure regulating mechanism in addition to a number of other components.

46. The thermostat of a car

As the thermostat works, it closes and opens the channels of the water jacket so that they can exit the radiator hose at the output channel. The thermostat is fully closed when the engine is at a low temperature. By doing so, the water jacket is able to keep the coolant circulating within a closed circuit. In order to increase the engine temperature faster, this circulation will be made possible by the coolant being used to circulate heat from the combustion chambers throughout all parts of the engine.

47. Output shaft of a car engine

The engine at the rear of the vehicle will actually have two output shafts, if it is rear-wheel drive. Engine accessories, such as power steering and charging, are driven by one on the front of the engine. From the rear of the transmission, you will see the second protrusion.

48. Crankcase of an engine

Engine crankcases house the crankshaft of reciprocating internal combustion engines. Engine blocks are integrated with crankcases in most modern engines.

49. Traction battery pack in a car engine

This particular part is generally present in modern electrical vehicles and is a very crucial part. A traction battery in an EV delivers electricity to the motor very quickly, providing rapid acceleration and high performance to the vehicle. The construction of EV traction battery packs is critical to understanding traction batteries & the challenges of extinguishing them should they ignite.

traction battery packs is critical to understanding traction batteries & the challenges of extinguishing them should they ignite.

50. Water circulating pump

A water pump is a device that has only one function, i.e., it circulates the coolant within the radiator so that it can reach the cooling channel, and that is it. In general, the water pump is located inside the water jacket, causing a flow of water to flow in the water jacket when the thermostat closes, thus helping to reduce engine heat when the thermostat closes.

51. Air Box of a car engine

The air box of a combustion engine is an empty chamber at its inlet. Each cylinder’s intake hose receives air from the outside and feeds it to the intake valve.

Air boxes allow one air filter to replace multiples, which reduces complexity. In response to engine emission concerns in the late 1970s, the air box was designed to collect pump gases from the crankcase and the tank air vent and re-feed them to the engine.

52. Engine power control unit

Inverters power the motor, boost converters boost voltage, and DCDC converters lower voltage in this highly efficient PCU. Power is supplied to the motor by the PCU during acceleration by converting battery power from DC to AC.

53. Cooling water reservoirs

A tube through the radiator cap will be used to channel the evaporated coolant into a tube in order to stabilize the air pressure in the radiator. As moisture condenses back into liquid form inside this tube, it will be able to form new condensations.

As long as the pressure within the cooling system is vacuumed, the transformed vapor can be re-channeled into the cooling system to be cooled. As a result, the coolant inside the system will not be reduced, which will prevent heat from accumulating.

54. Thermometer of a car

Coolant temperature is measured with the help of a thermometer. There will also be a display on the dashboard of the car which shows the results of the measurements taken. Modern cars are being replaced by engine coolant temperature sensors instead of this thermometer, which used to be present in cars of the past.

55. Waste-gate Valve

Turbocharger boost pressure does not exceed critical pressure by controlling the waste-gate valve. In order to improve fuel efficiency, turbochargers are often used with downsized engines.

56. Indicator in the dashboard

The thermometer still incorporates this sensor in order to determine the amount of coolant in the engine at any given time. By showing the coolant temperature in real-time on the dashboard display information panel, the driver will be able to get to know if the cooling system is malfunctioning, and thus, prevent the engine from overheating.

57. Carburetor

The purpose of a carburetor is to mix fuel with air when the air-fuel ratio for combustion is appropriate for internal combustion engines. If the carburetor is not functioning properly, the engine won’t work right, give the right horsepower, or run smoothly.

58. Carburetor adjustment tool

A carburetor adjustment tool is a type of special-looking screwdriver that is used on An engine’s carburetor adjustment tool controls how much air and fuel are mixed together in an engine carburetor using a special-looking screwdriver. An engine’s idle speed and smoothness can be adjusted by adjusting a screw that is present by using this particular type of screwdriver.

59. Engine Valve

In internal combustion engines, engine valves are mechanical components that allow or restrict the flow of fluid or gas into and out of the combustion chambers or cylinders during engine operation as a result of the engine operating.

60. Check Valve

A check valve may also be referred to as an engine valve, which is a type of check valve used for air injection as part of the emission control and exhaust gas recirculation systems in vehicles as a part of the emission control process

61. Bimetallic engine valves

This valve is made of two different materials called austenitic steel for the valve head and martensitic steel for the valve stem. The two materials are attached together using friction welding to create a valve that contains austenitic steel for the valve head and martensitic steel for the valve stem. In terms of their properties, each of these steels performs a different function with the austenitic steel providing high temperature resistance, corrosion resistance, and abrasion resistance on the valve stem and the martensitic steel for the valve head providing high tensile strength and resistance to wear.

62. Monometallic engine valves

An engine valve that is monometallic is, as its name suggests, made of a single material, which is used to fabricate both the stem of the valve as well as the head of the valve. It is important to note that these types of engine valves are both heat resistant and exhibit excellent anti-friction properties.

63. Hollow Engine Valves

It is important to note that hollow engine valves are unique bimetallic valves that contain a hollow cavity that is filled with sodium as part of its construction. It is believed that when the temperature of the valve head rises, the sodium liquefies and is circulated within the valve when the valve is being operated. Thus, the hotter the valve head becomes, the easier it is to dissipate the heat that has been generated. Since the martensitic material utilized in the stem is more effective at transferring heat through the valve stem than the austenitic material used in the head, the hollow design facilitates greater heat transfer through the stem than solid valves.

64. Induction Motor

In an asynchronous motor, the rotor is forced into rotation by the rotating magnetic field created by the stator, trying to catch up with it. Known for its high power output, this type of electric car motor is commonly used in vehicles.

65. Intercooler

As a result of the intercoolers, fuel consumption is reduced and engine power and efficiency are increased. By reducing the inlet gas’s temperature and densifying the air required, the intercooler optimizes combustion. Inlet gas temperature is lowered from 130°C to 60°C, turbo effects are removed, and around 20% more power is gained.

66. Car Engine battery

The size of a car battery should not be used to evaluate it. Despite being tiny, it is vital to the vehicle’s smooth operation. functions like starting your car, powering the infotainment system, turning on the lighting, etc. The battery in the automobile is charged by the running engine.

The battery gets very strained when you use your car frequently on short trips and stop and start continually. This is especially true in winter when your heater, headlights, heated windows and wipers may work the majority of the time. In order for all the electrical components in your vehicle to function properly, it is necessary to have a car battery to supply electricity to them. Your car will not start without battery power, as you are probably well aware.

A car battery charger is designed for the purpose of recharging the battery of your vehicle through the use of an electrical current. In order to recharge the battery, a charger should be placed in the wall outlet, which will draw out AC currents, which in turn will give the vehicle energy again in a few minutes once the charger is plugged into the wall outlet. There is no doubt that the charger is a lifesaver. You can use it easily, conveniently, and within your budget. There are simply too many benefits to using a battery charger.

67. Car Starter Switch

As the name suggests, a car starter which is also known as a self-starter, cranking motor, or starter motor is a device used in the internal-combustion engine to rotate or crank in order to initiate its operation under its own power by rotating. There are three types of starters: electric, pneumatic, and hydraulic. There are even cases when the starter of a large engine can be another internal combustion engine if the engine has a very large fuel tank.

68. Engine mount guard

The engine mount is made up of rubber materials that prevent the engine from rubbing against the frame of your vehicle due to metal-to-metal friction , several manufacturers have started producing liquid-filled mounts, which are similar to shock absorbers and are designed to increase both the dampening effect of the mounts and the vibration dampening.

Depending on the application and amount of energy they must absorb, engine mounts can take a variety of forms and designs. Because of this, most engine mounts are relatively small or just large enough for the damping and absorbing of the energy without taking up too much space and, as a result, the mounts are relatively small. In order to construct an engine mount, there are a few parts that need to be assembled.

Conclusion

Hi Friends, I hope we have elaborated the different parts of a car engine, along with diagram, functions. Still, if you feel you have doubt, please feel free to ask so that we can explain further in a better way! Stay blessed, happy reading!