Let’s explore centrifugal fan or blower fan! Air circulation is among the core phenomena that keep massive importance. The flow of air or circulation is maintained with the help of different kinds of machines. These machines are critically known as fans, air conditioners, fans, blowers, etc. it is pretty vital to get an idea about this aspect as it remains at the peak of human needs. We will explore Centrifugal fan or blower here!

What is Centrifugal Fan or Blower? Definition

Centrifugal Fan or Blower Basics

Centrifugal Fans or blowers are also one of the main kinds of fans or blowers used for industrial purposes. These centrifugal fans are apt for use in different sectors where one needs high-pressure applications. It is being used in numerous industries and also in air pollution systems.

- With the help of a Centrifugal fan, one can increase the pressure through impellers of an incoming airstream.

- In this, the series of blades mounted help in accelerating the air radially. Gradually it alters the core direction of outward flowing air.

- Centrifugal fans are known explicitly as constant volume devices that provide continuous airflow compared to their peers, such as axial flow fans.

- For this reason, it is being used widely in industrial applications as it is quite efficient.

Here we are going to discuss the centrifugal fans and their core applications elaborately. Not only this, we will try to provide an in-depth analysis of the working components used and many more related attributes. We will start with the core definition of the centrifugal fan.

Definition of Centrifugal Fan or Blower

Centrifugal Fans are also known as blowers, are the most versatile and efficient equipment for air movement. The centrifugal fans are equipped with scroll housing that helps in accelerating the air and helps in changing the direction almost to the right angle before leaving the housing of the same.

Centrifugal fans or blowers are most reliable and can be used in vivid environments and for numerous applications. There are many sectors where the use of Centrifugal fans is prominent. We are providing an overview of the same while elaborating them further as the article advances.

Why Does Centrifugal Fan or Blower Need?

Centrifugal Fans or blowers are among the core components of numerous devices and equipment. The main applications are based upon the usage as it is being used widely for the following purposes:

- Dust and gas extractor fans

- Back-flushing filters

- Gas boosters

- Air filtration and pollution control devices

- Industrial conveyors

- Vehicle engines

- Industrial furnaces

- Air conditioning systems

- Air handling unit (AHU)

- Ventilation system

- High capacity dryers

- Fluid bed aerators

Apart from the industry-specific usage, the following are the most commonly used in day to day life:

- Hairdryers

- Domestic extractor fans for kitchens and bathrooms

- Computer cooling fans

- Vacuum cleaners

- Roof ventilators

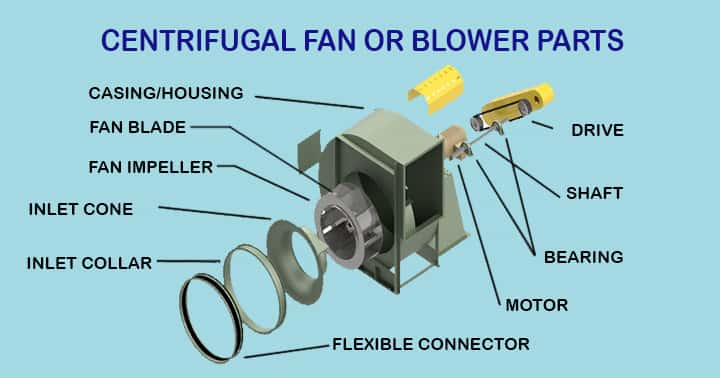

Parts of Centrifugal Fan or Blower

The core construction of the Centrifugal fan or blower is quite simple. Here we will discuss those components and the construction of Centrifugal fans. The following are the parts with which a centrifugal fan can be constructed.

- Fan housing

- Impellers

- Inlet and outlet ducts

- Driveshaft

- Drive mechanism

- Fan Dampers and Vanes

- Fan blades

- an discharge casing

Other subsidiary components include couplings, bearings, shaft seal plates, impeller locking equipment, etc. The most important is the centrifugal fan impeller which straight or curved metal blades can construct to the two sides of the rotor with the help of the welding process. In these, the casings of the blade are made up of sheet metal of varied thicknesses. In addition to that sealing, devices are used in between the shaft and the casing.

How Does Centrifugal Fan or Blower Work?

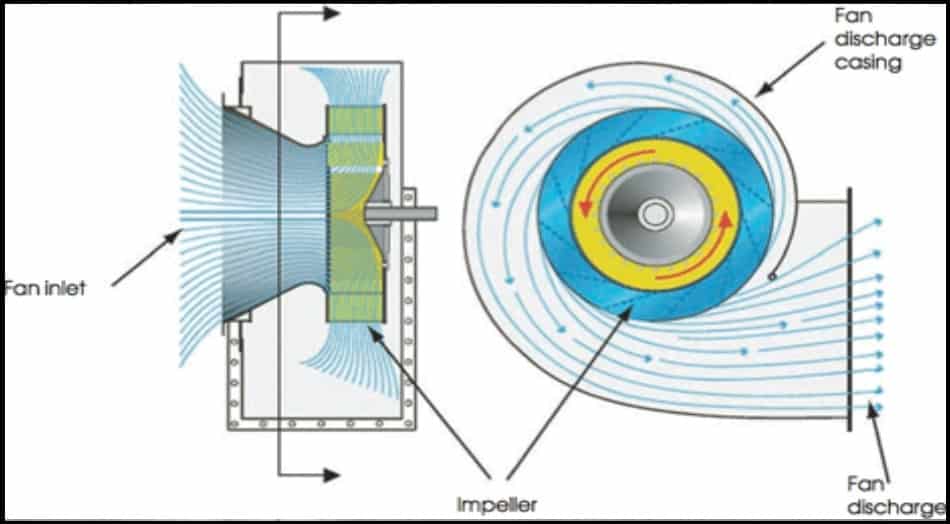

The working principle of centrifugal blowers is quite simplistic. They work with centrifugal force – the force created when an object moves around a rotation point. This effectively means that the impellers are equipped with rotors that help rotate and supply them with energy. In a centrifugal fan or blower, the curved blades rotate at a specified pace. This is covered within a shape that has a drum shape. These blades, which work continuously, are known as impellers.

In this, the air or gas enters the fan’s direction and the axis where the wheel is fixed. They are then provided with acceleration, and the fan and dust or gases are pushed out of the ducts. The gas or dirt exits by asking an angle at the entry point, which is the core route for exit.

How to Select Centrifugal Fan or Blower?

The selection of centrifugal fans effectively depends upon some of the parameters. These parameters should be considered at any cost as it helps in selecting an efficient one for the desired work.

Velocity

While choosing an appropriate centrifugal fan, the velocity at which the blades rotate provides the amount of airflow needed. It is required to get the desired flow that helps in proper ventilation. The airflow helps to remove the impurities through filters and ducts. If you have a massive or lengthy or complex duct system, it will surely need optimum power. In addition to the velocity, the impact of filters should also be considered as it directly affects the power and pressure needed.

Drive option

It is recommended to check the drive type as the direct drive is preferable for smaller centrifugal fans or blowers. It comes with a cost-effective approach, optimal efficiency, low maintenance, and par level reliability factor. If you opt for a belt-drive, it will provide maximum flexibility as it can be customized variable pitch motor pulley. These are typically apt for those places where we need larger centrifugal fans or blowers.

Environment or atmosphere

The place or environment where the centrifugal fans are going to be attached is among the main factors that should be considered while choosing the right one. It is recommended to keep a check on the motor installed as per the environment.

- If it is going to be installed in an outdoor environment, then TEFC electric motors can be installed on the drive units with a weather cover.

- For dust-prone areas, an Enclosed Fan Cooled (TEFC) motor can be used for prolonged life and optimal efficiency.

- For areas where corrosion is probable, one can use a centrifugal blower manufactured of stainless steel. It is recommended to opt for a stainless wash-duty motor to be installed with the fan.

- Sometimes, at places where the hazard is probable, we can use a non-sparking centrifugal blower or fan with an explosion-proof motor.

Specifications for Rotation and Direction of Discharge

While selecting a centrifugal fan, it is important to consider two factors that make it quite efficient. These two factors are considered because the inlet fans are the main parts that drive the air away.

Types of Centrifugal Fan or Blower

The centrifugal fans come in different varieties. These are constructed based on use as well as design. It can also be customized as per the applications. Some of the parameters that define the type of Centrifugal fans are discussed above. These parameters, such as the shape of the fan blade, size of the motor, materials used for construction as well as the direction of rotation, are the most comprehensive ones:

Based on overall construction

The overall construction of the centrifugal fans provides practical benefits. These are the characteristics that should be emphasized. The following are the main types of centrifugal fans:

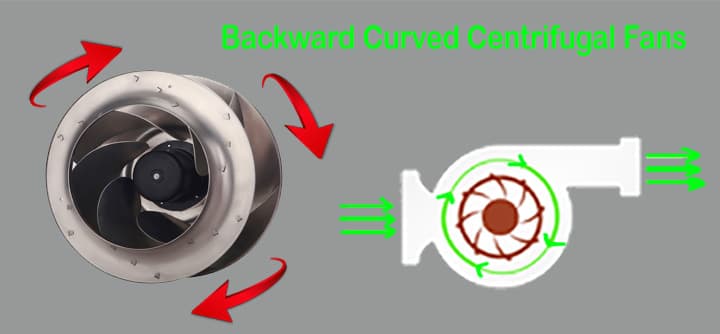

Backward Curved Centrifugal Fans

This is one of the types of centrifugal fans capable of providing par-level performance with minimum energy consumption. These properties make them valuable for different kinds of applications.

In this, the profile of the centrifugal fan helps provide support to cater to the high volume with optimal static efficiency and high pressure. These are most preferable for those places where there is a need for clean air.

- It can also be used in those industries where it is needed to pull air through a massive duct system. It also includes practical and customized design features.

- It is being widely used for air pollution control applications that make it quite secure and reliable. This mainly includes suit collectors, scrubbers, oxidizers, and many more.

- Some of the other applications of this centrifugal fan or blower are in Process Heating, Odor Control, and Diluted Air.

Backward Inclined Centrifugal Fans

The backward inclined centrifugal fans are optimally efficient ones equipped with flat, simple, and backward inclined blades. This kind of construction helps in minimizing the interference with the airflow. This is because the air moves through the fan effectively. With this, one can easily attain minimal sound and decrease energy costs compared to other types of centrifugal fans. In addition to that, the applications of these backward inclined centrifugal fans are pretty vivid.

- It can be used for all types of dust applications as it provides induced raft air by sucking dust-filled air via a dust collector.

- It can also be used for different kinds of Air pollution control methods.

- Apart from these, the other core applications of centrifugal fans and blowers are used for many industrial applications.

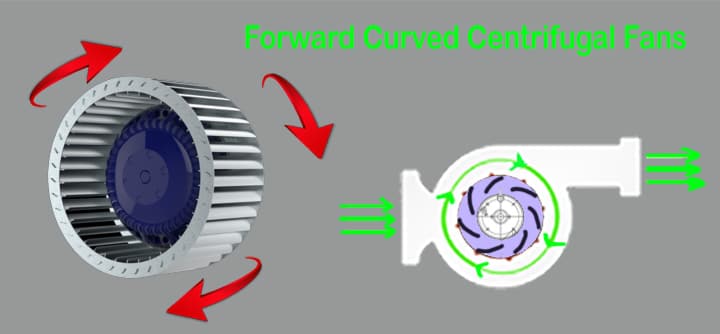

Forward Curved Centrifugal Fans

Forward curved centrifugal fans are specially designed ones that cater to high temperatures. It comes with a Radial paddle wheel fan that can easily take the maximum heat and helps in maintaining the airflow effectively.

There are numerous applications of this kind of centrifugal fan, especially for the high-temperature process heat.

- The high-temperature areas or applications need a fan that can withstand the high temperature without worry.

- The forward curve comes under that that can easily help circulate the heated air in the designated chamber.

- In this, one of the considerations that a designer should take is the proper design. A well-designed centrifugal fan can decrease the probability of failure to a massive extent.

Based on the shape of the blade

Blades of the fan remain at the topmost position when we talk about the construction of centrifugal fans or blowers. Their specific characteristics can obtain unique performance and efficiency. As we know, the prominent use of centrifugal fans is in industries, and for that, it needs to be maintained with all the characteristics such as static pressure, airflow volume, processing operational goal of the fan, and many more.

These variable properties should be considered. This is one of the significant characteristics is the shape of the blade. The following are the types of centrifugal fans that are constructed based on blades.

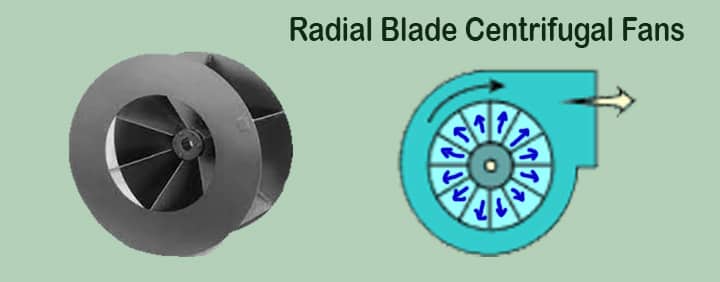

Radial Blade Fans

The radial blade fans are also known as paddlewheel fans. It is equipped with an impeller that has multiple flat blades that are equally spaced. In this, the wheel paddle is supposed to contain side rims also.

The radial blade fans are relatively heavier, narrower, and more profound than other kinds of centrifugal fans.

- These can produce high and medium pressure that can easily cater to massive volume or mass.

- These are critically used in those industries where material handling is needed.

Airfoil Blade Fans

The airfoil blade fans are equipped with hollow backward inclined blades. These are effectively apt for handling large amounts of clean air. It is effective for low to mid static pressure. This kind of centrifugal fan can provide par level efficiency and easily run at maximum speed than the other ones.

- These are also effective for large quantities of air.

- Those places where there is a need for extensive force, these kinds of blades are pretty effective.

- It can be used for different purposes such as HVAC systems, drying, filtration, air pollution control, and different industrial processes.

Radial Tip Centrifugal Fans

These are the kinds of Centrifugal fans that are based upon the blade shape. In this, the blade is backward curved and also equipped with cupping in the wheel rotation direction. The velocity produced by this centrifugal fan helps to move the volume of air. These are designed with ultimate precision as it is equipped with a compact design.

- It is ideal for applications where there is a need for a high-volume flow rate.

- It can also be used at those places where the requirement of pressure is also high.

- It also comes in among the mid-range centrifugal fans, which come with comparatively greater efficiency.

Inline Centrifugal Fans

These are the type of centrifugal fans which come with robust construction that is equipped with backward inclined type wheels which are enclosed in tube casing. It is preferred to use an axial tube casing for better performance.

These come under the medium-duty fans that provide airflow in a straight direction.

- However inline centrifugal fans are less effective and can only be used to apply ventilation or heating.

- The above are some types of centrifugal fans designed based on volume, pressure, airflow rate, efficiency, and size.

- These can be used in multiple kinds of applications in the industries.

Based on Inlet & Width

Based on nos. of inlet and width, centrifugal fan is categorized into two types.

- SISW

- DIDW

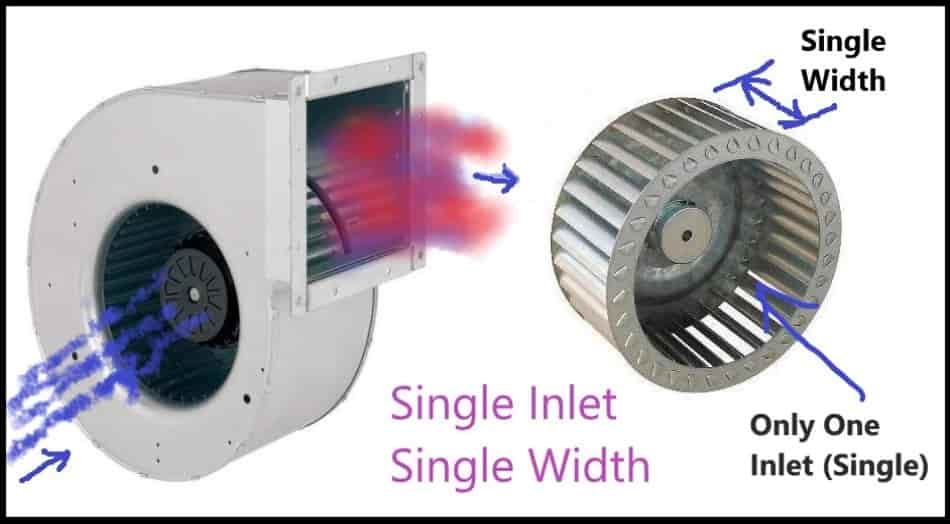

SISW (Single Inlet Single Width) Centrifugal Fan

As the name suggests, SISW centrifugal fans mean,

- It is single inlet that means only one inlet

- It consists single width, that means only one side on impeller is working

- Space requirement is less

- Comparatively low volume application with respect to DIDW fans

- Less power consumption with respect to DIDW

- Fan width is less

- Inlet can be ducted

- Thrust bearing is required to tackle the thrust created due to one side action

- Heat gain is comparatively less, as inlet can be ducted

- Efficiency is comparatively high around 5-15% with respect to DIDW fan

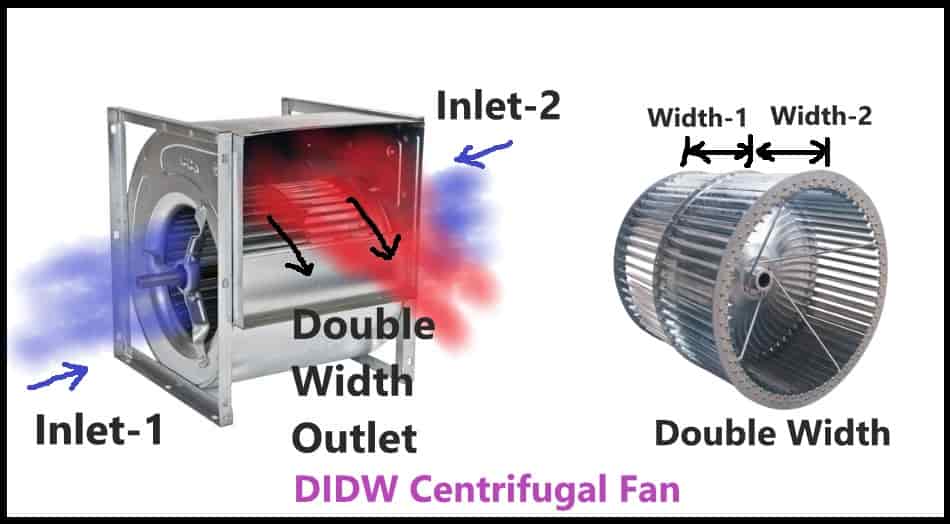

DIDW (Double Inlet Double Width) Centrifugal Fan

As the name suggests, DIDW centrifugal fans mean,

- It is double inlet that means two inlets. One inlet in each side.

- It consists double width, that means two sides on impeller are working. Air will enter from both the inlets and strike one each side of impeller.

- Space requirement is more.

- Comparatively high volume application with respect to SISW fans.

- More power consumption with respect to SISW. Normally, 15-18% power higher than SISW fans.

- Fan is balanced, hence, no thrust bearing is mandatory.

- As this fan inlet is open, it incurs heat gain.

- Efficiency is comparatively less.

What is the difference between SISW and DIDW Centrifugal Fan?

There are many differences between SISW Centrifugal fans and DIDW Centrifugal fans and these are tabulated as follows:

| Parameter | SISW Centrifugal Fan | DIDW Centrifugal Fan |

| Inlet | This type of fan has only one inlet | This type of fan has two inlets |

| Impeller | Only one side of impeller is working | Both side of impeller is working |

| Impeller construction | Single impeller, with one side working | It looks like two impellers are place back to back |

| Air/gas entry | Air or gas enters through one inlet & strike one side of impeller | Air or gas enters through both side of inlet & strike both side of impeller |

| Thrust bearing | Required | Not mandatory |

| Space | Low space required | Comparatively large |

| Power consumption | Less | High, with respect to SISW fans |

| Efficiency | High | Comparatively less, 5-15% less |

| Maintenance | Easy | Little difficult |

| Motor | Motor can be placed without any contact with process air or gas | Motor will be in contact with process air or gas |

Difference Between Centrifugal fan and Axial fan

After getting all the ideas about the Centrifugal fans, it is now the time to get equipped with all the information that differentiates it from one of the other fan types known as Axial Fans. Before getting to the differentiating factors, it is prescribed to get a brief introduction of Axial Fans. The common difference between an axial fan and centrifugal are tabulated, as follow:

| Parameters | Axial Fan | Centrifugal Fan |

| Driving Force | The main driving force to operate an axial fan is axial. | The main driving force to operate a centrifugal fan is centrifugal force. |

| Construction | The construction of axial fan is very basic & simple | The construction of centrifugal is complex with respect to the axial fans. |

| Size | It’s compact | It’s bulky |

| Blade mounting | In this, the fan blades are mounted on the rotor hub’s circumference. | The blade of centrifugal fans is specifically mounted on the rotor radially. |

| Airflow direction | The blades are capable of rotating and providing airflow in the parallel direction of the rotor axis. | These blades can provide airflow perpendicular to the rotor axis, which in turn helps in the circulation of air throughout. |

| Location of motor | The whole parts, such as the rotor, blade, and other parts, are enclosed in a casing that protects them from debris and dust. | The motor is placed outside the casing and a shaft is connected to the blade & motor. |

| Working | While in Axial Fans, the blades are mounted on the whole periphery of the rotor. These are rotated with the help of an electric motor. The air inflow happens from one end, and pressurized air outflow takes place with the apt force from the other end. This intake and outlet work in parallel to the central axis of the rotor. | In the centrifugal fans, the air gets succumbed inside the rotary hub when the blade rotates. It is equipped with an eccentric rotor due to which the air is first compressed and provides an exit with optimal force. This happens due to centrifugal action. |

| Airflow Capacity | For the axial fans, the airflow or delivery remains at 100 cubic feet per minute (170 cubic meter per hour) to 5,00,000 cubic feet per minute (8,50,000 cubic meter per hour). | The air delivery capacity of centrifugal fans remains at the lower end from 500 cubic feet per minute (850 cubic meter per hour) to 1,25,000 cubic feet per minute (2,12,500 cubic meter per hour) |

| Operating Speed | Normally axial fan has a comparatively high operating speed in comparison with a centrifugal fan. | Normally centrifugal fan has comparatively low operating speed in comparison with an axial fan. |

| Pressure | Normally axial fan creates low static pressure with respect to centrifugal fan | Centrifugal fan creates high static pressure with respect to axial fan |

| Power Consumption | Low comparative to Centrifugal fan | High comparative to an axial fan |

| Ductwork | Normally, not required, however, in case of ducted axial fans like inline fans, ductwork is required. | Normally ductwork is required at the outlet of the fan. |

| Vibration | Less | High. To mitigate it, a vibration isolator is required. |

| Weight | Light | Heavy. |

| Maintenance | Low | High |

| Applications | The core applications of axial flow fans are for heat exchange. It is widely being used in power generation plants. | Centrifugal fans are used for industrial ventilation, numerous HVAC operations, and package cooling towers. |

How to Size a Centrifugal Fan or Blower?

We have understood the basic details of centrifugal fan, now, how to select this fan? Let’s try to understand in brief. There are three main criteria of selection:

- Design calculation

- Required static pressure

- Density of air

Step#1 Design calculation

The first step is to calculate the air quantity based on the application as well as design criteria. For example, if it is to be selected for air conditioning system, we have to do heat load calculation for the areas to be air conditioned. This calculation will give air quantity.

In case, centrifugal fan to be used for the ventilation system, we have to do the calculation for ACPH, and heat load method & need to select whichever is higher. Say, the air quantity, Q = 2941 ft3/m [1920 l/s (litre per second) or 5000 m3/hr]

Step#2 Static Pressure Calculation

We have learned that centrifugal fan is able to create high static pressure in comparison with axial fans. Hence, if the static pressure that means the resistance to the air flow is high, centrifugal is envisaged. This resistance comes from the follows:

- Duct

- Flexible connections

- Dampers

- Bends

- Louvers,

- Grilles

- Diffusers

Say, static pressure measured as 500 Pa.

Step#3 Temperature & Pressure of air

If the temperature various, air density will change. Now, temperature and pressure vary with respect to the elevation level. So, it is clear that due to variation of temperature, air density also will vary. Hence, performance will also vary. Hence, during selection of centrifugal fans, air temperature & pressure or elevation level to be considered.

Step#4 Space Constraints

If the space is very less, wall mounted axial fans can be an alternative option instead of centrifugal fan. However, for large flow and high pressure requirements, centrifugal fan should be managed to install for optimum results.

Centrifugal Fan Selection Example

How to select a centrifugal fan or blower for 2941 ft3/m at 10 inch WG at 80°F and at 6000 feet elevation.

Let’s solve it with guidance,

Step#1: We got the air quantity Q = 2941 ft3/m

Step#2: We got the static pressure 10 inch WG. Now, at 80°F, we have to find the actual static pressure due including temperature correction factor. Check the temperature correction factor from the above table. Say at 80°F and at 6000 feet elevation, Factor = 1.28

So, the static pressure, SP = 10 inch x 1.28 = 12.8 inch WP.

Step#3: Now, we have to find out the centrifugal fan from the fan catalogue with respective to 2941 ft3/m & 12.8 inch WG

Applications of Centrifugal fan or Blower

The application of a centrifugal fan doesn’t restrict only to one sector. The most prominent use of centrifugal fans is for industrial processes. The following are some of the functions in the industrial sector:

- Air handling system: The most prominent and common use of centrifugal fans is in the operations and facilities of industries. It is used for maintaining the ambient air in the atmosphere. These are used for refreshing the air and are equipped with those components that make up air units. Most of the industries are using centrifugal fans as the main equipment for air handling.

- Dust loading and fume extraction: The industrial processes that have the core work of dust loadings, such as mining industries or metallurgical plants, need centrifugal fans for the proper airflow. It helps in maintaining the air quality as well as maintaining safety. These are used for moving the air and materials through a specified system that collects, captures, and conveys the particles to different parts of the system.

- Material handling system: This is one of the foremost areas where the centrifugal fan is used. In material handling

, the centrifugal fans can easily help process sawdust, grain, paper trim, wood chips, and numerous others—these range from larger to abrasive materials.

, the centrifugal fans can easily help process sawdust, grain, paper trim, wood chips, and numerous others—these range from larger to abrasive materials. - Saturating different mixtures: Centrifugal exhaust fans are the best alternatives that can be used for saturating the air. It means that at every point of the applications in industries where heavy-duty materials coating is required, the centrifugal exhaust fan keeps the dirt or any kind of other impurities away.

- Attaining optimal temperature: Numerous industries primarily relied on high-temperature generation. High temperature is the core of operations-oriented companies such as heat treatment plants, industrial furnaces, and many more. To circulate the heated air within the chamber, a centrifugal fan is used. These are specifically designed fans that can withstand high temperatures.

- Customized Centrifugal Fans: Different industries use centrifugal fans as per their need. They select the fan based on core needs. Some remote industries use these centrifugal fans according to their needs. The requirements and the budgets dependencies are core factors for these companies.

Things to Remember while Installing Centrifugal Fan or Blower

If you install a centrifugal fan in any area, then some of the parameters should be considered. These parameters define the efficiency and productivity of the centrifugal fans. They are as follows:

- Direction of rotation and angular reference should be determined based on inlet fans and drivers.

- Direction of discharge is also among the essential factors while installing a Centrifugal fan. The angle of discharge and the desired degrees at which it can provide effective airflow is needed. This can only be attained by proper planning and working out with the help of diagrams.

- Apart from the above two, checking the fans for ISO certification and the associated ratings are recommended. This will help you to get an effective and productive product for the desired need.

Conclusion

Centrifugal fans and blowers are among the most efficient equipment available for different kinds of industrial applications. These can be quite efficient and can help in almost all the purposes related to airflow or cleaning. There is a need for proper ventilation and chilling of the airflow, but it also becomes quite productive.

Here we have discussed all the things related to centrifugal fans; however, scopes of elaboration can provide us with adequate information. This excerpt holds all the important sections such as working, applications, parameters to check for while selecting a centrifugal fan, and many more. With this, one can easily get equipped with all the vivid data set regarding the centrifugal fans. We will try to provide some more in-depth information regarding the centrifugal fans in our upcoming articles. Any questions, please let us know!