In this article, we will learn what are chillers in HVAC system, along with the definition, meaning, working, types, selection, applications, advantages, disadvantages, etc. Let’s explore!

What are Chillers in HVAC? Definition & Meaning

Chillers are widely used machines to remove heat from a liquid, and they are extensively used in industries. There are several chiller options available. The application, cooling temperature requirements, and cooling characteristics need to match the needs when choosing one. Significant parameters to ponder are the operating temperatures and pressures.

They vary in size; small chillers are available for smaller applications. While commercially or industrially, large chiller units are required, but the basic principle stays intact, and they provide cooling for HVAC systems as well as for the process industries.

Chillers are significant to use. Machines are never 100% efficient, and they produce a lot of heat as a by-product that needs to be removed. If not removed, it can cause many issues such as reduced production times, equipment shutdowns, and premature equipment malfunctioning. Hence, it is essential to incorporate cooling into air conditioning systems and industrial process to prevent such problems.

- Industrial chillers function through a refrigeration system that removes heat and transfers it to somewhere else.

- They are used to lower the temperature of machinery, industrial spaces, and process fluids.

- Hence, these industrial chillers play a vital role in temperature regulation in several industrial operations such as HVAC systems, injection molding, oilfield production, metal plating, and food processing.

- Similarly, chillers are also found in medium to large-sized buildings to produce chilled water for air conditioning.

- All types of chillers differ slightly; however, the essential components and working principles stay intact.

Principle of Chiller’s Operation

Chillers operate on some principles. They are:

01. Phase change in Chillers

The liquid coolant or refrigerant undergoes a phase change and transforms into a gas when heated. This phase change started in the evaporator. At normal pressure & temperature, refrigerant starts evaporating which means liquid refrigerant changes its phase into gas. This gaseous refrigerant or coolant will condense back into liquid when supercooled.

02. Heat flow in Chiller

Heat flow is an important aspect that takes place in chillers. Heat energy always flows from an area of high concentration of heat to an area of low concentration of heat.

03. Boiling point of Refrigerant

We know that boiling point and pressure have a relationship. If pressure is increased then the boiling point will increase and if pressure is decreased then the boiling point will be decreased.

Hence, the boiling point of the refrigerant reduces when pressure on the refrigerant decreases and the boiling point of the refrigerant increases if the pressure of the refrigerant increases. These are the basic working principles of chillers. The essential components of chillers and working are further discussed in-depth in terms of these principles.

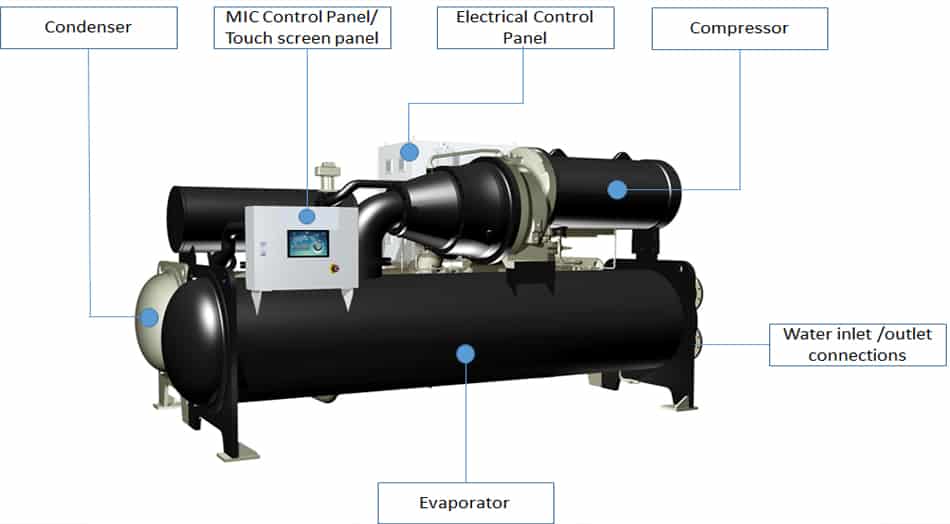

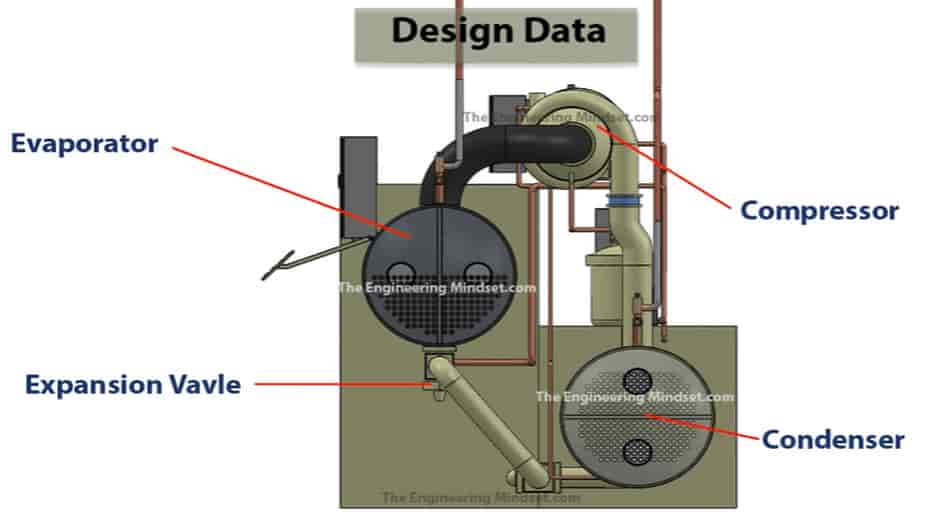

Parts of Chillers in HVAC system

The basic components of chillers found in all types are:

- Compressor

- Condenser

- Evaporator

- Expansion valve

- Power panel

- Control unit

- Water box

01. Compressor

There are numerous types of refrigerant compressors; the widely used ones include scroll, screw, centrifugal, and reciprocating types of compressors.

- Each of them has its own merits and demerits, but the compressor is the prime component of the chiller.

- It is located right between the condenser and evaporator of the chiller and is insulated.

- There is a motor attached either externally or internally to the compressor as a driving force.

02. Condenser

The condenser is located next to the compressor, right before the expansion valve. The evaporator picks up heat from the refrigerant, and this heat needs to be removed.

- For this purpose, the chillers have condensers installed in them.

- The function of the condenser is slightly different in water and air-cooled chillers.

- They are among the types of chillers discussed in detail in the “types” section of the blog.

03. Expansion valve

There is a valve present between evaporator and condenser, which is known as an expansion valve. The common types of expansion valves fitted in chillers include pilot-operated thermal expansion valves, electronic expansion valves, thermal expansion valves, and fixed orifice expansion valves.

- Despite the different types, the primary function is the same.

- Expansion valves function by increasing refrigerant volume and decreasing the pressure to easily pick the extra heat from the evaporators.

04. Evaporator

Between the expansion valve and compressor, there is an evaporator. The primary purpose of the evaporator is to collect the extra heat and move it into the refrigerant, which sends it further to the cooling tower.

- When heat is extracted from the refrigerant, water cools down.

- The chilled water is then utilized in producing cooling.

- It then returns to the evaporator so that the unwanted heat is removed again. In this way, the cycle continues.

05. Power Panel

The power panel is mounted on chillers in industries; it may be mounted directly to chillers or fixed to the room’s wall where the plant is located.

- The power panel constitutes many power cables, and its function is to control the flow of electrical power to the chillers.

- The primary components of the power panel are circuit breakers, starters, speed controllers, and power monitoring equipment.

06. Control unit

The control unit is located on the chiller. It monitors several aspects like the chiller’s performance and has adjustments for the proper functioning of the chiller.

- In case of emergencies, it can generate alarms and automatically turn off the system to prevent hazards.

- For remote control and monitoring, BMS connections are also available in the control unit.

07. Water box

Water boxes are present along with condensers and evaporators in water-cooled chillers. The number of entrances in the water box depends on the number of passes in the evaporator and condenser.

The primary function of water boxes is separating the entrance and exit paths and also aids in directing the flow. You can explore AHU video with Site Tour

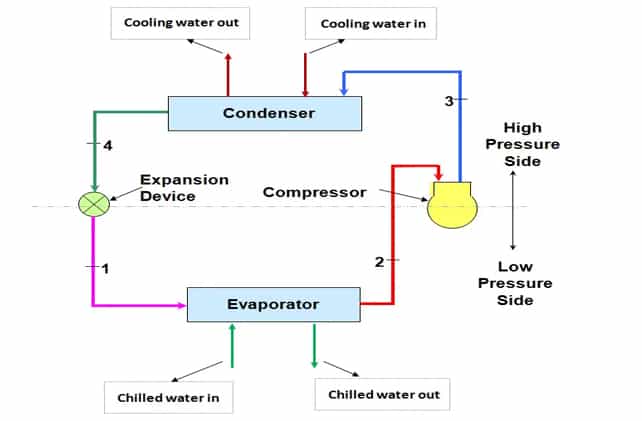

How Does Chiller Works?

After discussing the working principle and components, let’s get into the working process of chillers. A pumping system circulates cool water or glycol solution (for process chillers) from the chiller into the required areas. The cool fluid removes unwanted heat from the process when hot liquid returns—the heat transfers from the system to the chiller by water.

Different types of pumps are used in chilled water systems. Chiller is a part of a chilled water system. Below pumps are used for chilled water system.

- Chilled water pumps for circulation of water from chillers to the system or building or process which needs to be cooled.

- Condenser water pumps for circulation of condenser water between condenser and cooling towers.

- Dosing pumps are provided for the chemical dosing in chilled water pipes to reduce the formation of scale.

A chemical compound known as a refrigerant is present in chillers. There are several types of refrigerants depending upon the required temperatures. For examples,

- R134a

- R410a

- R1234yf etc.

However, the basic principle of compression and phase change of refrigerant from liquid to gas and back to liquid stays intact. This whole process of phase change, heating, and cooling is known as the refrigeration cycle.

The refrigeration cycle begins with a low-pressure liquid/gas mix that enters the evaporator. The heat from process water or water/glycol solution boils the refrigerant inside the evaporator. It results in a change from a low-pressure liquid into a low-pressure gas.

Now, the compressor compresses low-pressure gas into high-pressure gas. This high-pressure gas enters the condenser, where ambient air or condenser water removes the heat. In this way, the high-pressure gas converts to a high-pressure liquid.

The high-pressure liquid now enters the expansion valve. The valve controls the amount of refrigerant liquid entering the evaporator, allowing the refrigeration cycle to start again. The condensers are of two types; either water-cooled or air-cooled. In the latter, water from the cooling tower is used to cool and condense refrigerants. On the contrary, the air-cooled condenser uses ambient air to cool and re-condense the heated refrigerant gas into the liquid.

Types of Chillers

There are numerous types of chillers. Chillers are both commercially and industrially used for cooling. The types are:

01. Water-cooled Chillers

Water-cooled chillers are the most common type of chillers, and they utilize water from an external tower to cool the gaseous refrigerant in the chiller’s condenser. In this way, refrigerants can undergo a phase change, and the refrigeration cycle goes on.

- They are pretty efficient as compared to air-cooled chillers.

- Moreover, they are versatile because they are used for both small-scale and industrial purposes.

- They are compact, portable, and quieter.

02. Air-Cooled Chillers

Instead of water, air-cooled chillers use ambient air for the refrigeration cycle to go on smoothly. Air fans are attached to them, which makes the cooling process pretty speedy. On the contrary, they are preferred less because they produce a large amount of heat. However, they are used in colder areas where heat discharge can keep the place warm. This way, it is beneficial.

- Air-cooled chillers are cost-effective both in maintenance and installation, and it is available in portable solutions also.

- However, they use cooling fans that are pretty noisy, and Air-cooled chillers have a shorter life span than water-cooled chillers.

Classification of Industrial Chillers

Industrial chillers are further classified into the following types based on the transportation of refrigerant inside the system. The types are discussed below.

01. Vapor compression Chillers

Vapor compression chillers extract extra heat using a compressor to pump refrigerant.

- The primary components stay the same, but it does not have an absorbent medium as in vapor absorption chillers.

- These chillers use electricity, steam, or gas turbines to power a mechanical compressor, and the cooling is produced using a vapor-compression refrigeration cycle.

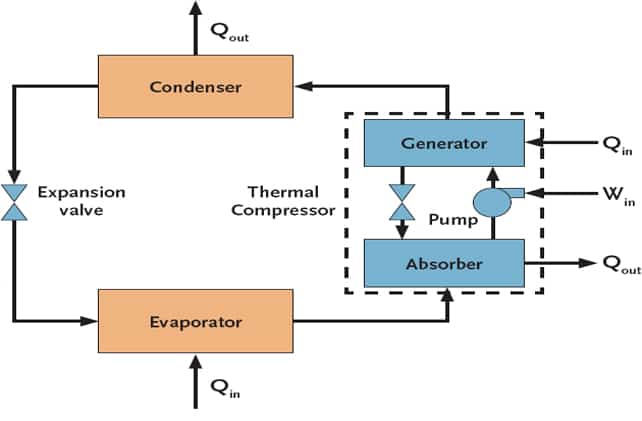

02. Vapor Absorption Chillers

Vapor absorption chillers transport the refrigerant around the system for cooling using a heat source heated using water or steam.

Let us see how a vapor absorption machine looks like at actual:

- The absorption medium is ammonia or lithium bromide, and the adsorption solution is regenerated through water or a stream.

- The components constitute an absorber, generator, and pump, and It doesn’t have a compressor as in a vapor compression chiller.

03. Screw Chillers

Screw chillers are vapor compression chillers, and it uses a screw compressor to move coolant through the system. They are most suitable for high-rise buildings and offer high energy efficiency. Other benefits include low maintenance costs, quiet working, and compact installation.

04. Centrifugal Chillers

Centrifugal chillers are vapor compression chillers best for medium to large-scale cooling operations. They comprise an evaporator, compressor, condenser, and expansion valve fitted with a rotating impeller which aids in compressing the refrigerant and then transporting it through the system.

05. Reciprocating chillers

Reciprocating chillers use reciprocating compressors. They are pretty efficient as they deliver small refrigerant quantities at high pressure.

06. Scroll chillers

Scroll chillers constitute two spiral plates, one fixed and the other rotating to compress the refrigerant—the momentarily separating scrolls with a solenoid valve and electric modulation controls capacity.

What are the Common Issues Arise in Chillers?

Machines work well, but sometimes issues arise. Chillers are also machines, and there are a few common issues that you may face. They include:

01. Corrosion

Metal tubes (copper or carbon steel) are used to construct chillers, and their primary function is transferring water between the chiller and climate-controlled space.

- Corrosion occurs because of oxygen, but we can overcome the risk through appropriate preventive measures.

- If the water treatment is inadequate, the system is vulnerable to sediments, minerals, and bacteria.

If sediment or bacteria builds up, the oxygenation level is disrupted, and metal corrodes. When two metals are used at some point in the system, there is more risk for corrosion.

It is due to differences in the electrochemical properties of both metals. Corrosion is terrible since it can cause leakage and damage the chiller and surrounding area, reducing the efficiency of chillers.

02. Maintenance problems

It is necessary to ensure that chillers are working correctly, for this maintenance is required. If not maintained adequately, it can lead to corrosion, clogging, loss of efficiency, and numerous other issues.

- The cooling towers need to be cleaned from time to time to prevent clogging in pipes due to the accumulation of particulates or sediments.

- Hence ensuring power maintenance is vital for the maximum efficiency of chillers.

03. Electrical issues

The electrical system inside chillers is complex and is vulnerable to malfunctioning. A high voltage surge can throw off balance and cause wear and tear in the whole electrical system.

- Similarly, overloading the chiller can cause overheating, which results in electrical issues.

- Apart from this, the wires and cables may become loose over time, resulting in electrical malfunctioning.

Selection of Chillers in HVAC System

Every environment is different, and every application requires a specific chiller for best results. Below is a quick guide that will help you in selecting the appropriate chiller for your application.

Step 1: Calculate the heat load based on all design parameters

The first step before selecting a chiller that best suits your needs is determining the heat load. It is better to understand the process first to calculate the accurate heat load in kW. It is important to ensure that the chiller you are choosing is appropriate for the intended application.

Step 2: Determining the Type of system, Cooling Medium, Temperature, and Flow Rate

After knowing the heat load, determine the coolant type, temperature, and flow rate. It is determined through the method of heat transfer from the process to the type of coolant used. For instance, water-cooled and air-cooled chillers have different characteristics.

Step 3: Environment Conditions

The third step involves knowing the environment. It may be outdoor or indoor. Therefore, the requirements for both environments slightly differ; hence you will need specific accessories for that. For instance, the outdoor environment needs accessories like air filters or sump heaters since chillers are vulnerable to a number of factors.

Step 4: Know the Performance Curves of Chiller

Use the chiller performance curves available with each model. Considering the application, an appropriate frame size is selected, and the capacity of the chillers and safety margins are taken into consideration.

Step 5: Know the Performance Curves of Pumps

Consult experts for pump performance curves. It is essential to ensure that the pump will provide enough pressure at the design flow rate that is best suitable for the application. For instance, some liquid-cooled systems have small coolant flow paths or longer distances resulting in higher than average pressure losses.

Step 6: Selection of Final Chiller

The final step involves considering power characteristics, control options, agency listing, color, footprint, size, etc.

- It will aid in choosing the correct chiller for your application.

- In the long term, choosing the correct one will provide premium performance and more excellent reliability.

Applications of Chillers in HVAC

Chillers are widely used on a small and large scale. The applications are given below:

- Restaurants use chillers to keep the area cool because many customers visit and eat food inside restaurants.

- They are globally used in shopping malls. Many people visit malls, so it’s essential to keep the temperature at normal levels to ensure a comfortable environment for customers.

- Mechanical industries manufacture gadgets and other electrical products on a large scale. Hence, large quantities of heat are produced. For the machines to work correctly, it is crucial to maintain an average temperature. Chillers are used for cooling here.

- Large buildings typically use water-cooled chillers with centrifugal or turbocor compressors within a central plant cooling system. They additionally use air-cooled chillers for producing cooling in computer or communication rooms.

- Medium-sized buildings with a cooling load of 200 – 400 tons of refrigeration or 700 – 1,400 kW use water or air-cooled chillers with screw or turbocor compressors.

- Small buildings with cooling loads under 200 tons or 700 kW use scroll compressors, Turbocor compressors, and air-cooled chillers.

- Absorption chillers are used when there is an abundance of high-quality waste heat or cheap heat. We mostly find them in hospitals and buildings with heated swimming pools. Moreover, commercial office-type buildings also use these types of chillers.

- Beverage industries involve pasteurizing, cooking, and mixing. These different processes need an environment within a specific temperature range, and Chillers can maintain that temperature range very efficiently and effectively.

- Plastic industries widely use chillers because there is a lot of machinery involved in manufacturing plastic. One of the critical steps is cooling the hot plastic, which is achievable using chillers. Hence, it keeps the equipment cool, and the industries work appropriately.

- Magnetic Resonance imaging is significant in the field of medicine. MRI scanners generate a large quantity of heat, and MediChillerslers are used to keep them cool and make them last longer.

Advantages of Chillers in HVAC

There are numerous advantages of using chillers in businesses. Some of them are listed below.

- Industrial machines overheat, and it may result in the collapse of machinery. It would be costly to replace them. Hence, chillers are used to protect machines or equipment.

- Chillers circulate water; therefore, they are cost-effective.

- They are more practical and efficient than water towers.

- They are installed with special units. Chillers produce heat exhaust during operation, but these special units recover the energy and utilize it as a cycle.

- They are budget-friendly and give higher cooling levels, making them ideal for industrial processes.

- They are not exposed to rain, snow, heat, ice, etc., making them less vulnerable to malfunctioning, ultimately resulting in longevity.

- Water-cooled chillers are widely used and preferred because of their quiet operation.

- Chillers, especially water-cooled chillers, are energy efficient.

- They are available in different sizes to tackle space constraints.

- The use of water makes them safe for people who are in constant contact with the system.

Disadvantages of Chillers in HVAC

Along with the advantages, every system or machine has disadvantages, and some of them are discussed below.

- It’s a hassle to install water-cooled chillers resulting in higher labor costs.

- Air-cooled chillers produce large quantities of heat at the site.

- Maintenance such as periodic inspections, water treatments to remove impurities, and regular cleaning of the chiller’s machinery is required. With more parts, the care becomes hectic, especially in water-cooled chillers.

- A mechanical room is needed to house a water-cooled chiller.

- In case of a water shortage, water-cooled chillers can’t be used.

- Chillers operate less efficiently if the surrounding environment is humid.

Conclusion

The article gives an insight into the working principles, types, categorization, application, merits, and demerits of Chillers in HVAC systems. Chillers are widely used on large and small scales to remove heat from liquids, and it comes in several types like water-cooled and air-cooled chillers.

Industrial chillers are categorized into different types: vapor compression, vapor absorption, screw, scroll, centrifugal, and reciprocating chillers. These cost-effective and budget-friendly machines are globally used, but they are vulnerable to malfunctioning due to corrosion, electrical issues, and negligence in maintenance. Therefore, it’s vital to ensure adequate care for proper working.