In this article, we will learn what is a crane machine or machinery, its definition, working, types, applications, advantages, disadvantages, applications. Let’s explore!

What is Crane Machine or Machinery? Definition

Crane Machine Definition

A crane machine or crane machinery is a mechanical lifting machine used to lift and carry lower materials. Crane is usually equipped with a winder, wire ropes, and sheaves that can be used to uplift the lower objects and heavyweights.

- A crane machine works through one or two machines to produce mechanical superiority, making a weight move far beyond human capabilities.

- There are different types of cranes, and each type is distinct depending on the kind of crane operation.

- For small span work, a smaller crane is used, and for higher and extensive span work, large cranes are used.

Why Does Crane Machine Require?

Crane machines are enormous machines commonly used at construction sites to move, lift or transfer a heavy-weight object or material from one place to another. Cranes are considered the essential mechanism on construction sites.

- The cranes that might look very simply designed, composed of ropes, chains, and wires, are easier to use and make the work easier for projection.

- Working on construction sites has always been considered precarious, but that’s where technological development plays its role in lessening the difficulty of the laborers.

- Cranes are essential for construction sites and are used in industries, mining processes, and even relief work like fire fighting. Hydraulic and Electrical cranes are mainly used in the construction and industrial sector, respectively.

Principle of Operation of Crane Machine

There are several types of cranes, and each crane type has its mechanism and working principles. We will discuss the working principle of each crane in the upcoming section ‘Types of cranes’. But some principles are common in most cases. Cranes use mechanical arms either driven by electrical power, hydraulics, or combustion engines. On most construction sites, a tower crane is used to transport heavy loads from one part to the other.

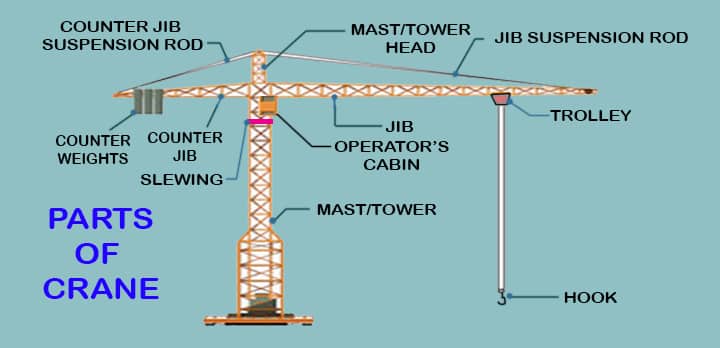

Parts of Crane Machine or Machinery

A crane machine consist of the following parts:

- Mast

- Jib

- Counter jib

- Counterweight

- Ballast

- Trolley and hook

- Slewing Ring

- Operator’s cabin

Mast

The mast is the part of the crane that provides the necessary height to the crane. It is a metallic lattice structure with a standard square section.

- Lattice structure consists of lattice modules that facilitate the transport of the crane.

- Lattice modules are designed on specific dimensions depending upon the load limit, and all of the modules are screwed together.

- Mast performs another function in the upper part which is to provide 360-degree horizontal movement.

- In other words, we can say that jab offers the base for the free movement of the crane.

Jib

The horizontal metal lattice framework with rectangular sections is termed the jib. The jib provides the crane the necessary radius or range and facilitates its transport like the mast jib.

Counter Jib

The counter jib is the part of the crane which performs the crucial of keeping the crane balanced.

- Counter mass is attached with the counter jib, and its length varies between 30 and 35 of the pen length.

- It provides a pathway to specialized personnel from mast to the counterweights.

Counterweights

Counterweights are the blocks of prefabricated blocks attached with the counter jib to maintain the balance of the crane. Stabilization of weight and inertia can be made possible only by this part of the crane, and it stabilizes the crane whether it’s working or in its state of rest.

Ballast

Ballast is the part of the tower crane formed by fabricated concrete and is present at the crane’s base. Maintaining the pressure of the crane’s weight and endurance of adverse environments is performed by the ballast.

Trolley and Hook

The trolley is the part of the crane that supports weights to be carried. The trolley consists of a cart that moves along the jib through some lanes, giving the crane the necessary movement.

- The hook is attached to the lifting cable that carries the weight of the object to be displaced.

- The lifting line is one of the most intricate parts of a crane, and it should be maintained correctly to maintain the crane’s performance.

- It should be an inextensible properly tensioned wire having weight attached to it.

- If any malfunctioning in the wire, the wire may not wind appropriately in the drum and might result in crushing.

Operation Chamber

The crane’s movement is controlled by the control center of the crane, which is the operation chamber. An operation chamber contains the operator’s chair, joystick, control system, monitoring devices, and communication system.

Slewing Ring

Jib, counter jib, cab, and tower top are collectively referred to as slewing units. Slewing ring drives or moves the slewing unit circularly or rotationally around the jib.

- Slewing ring is powered by slewing gear drive.

- Slewing ring is fixed to a ball track and consists of several hundred geared teeth.

- Slewing can produce enormous torque, yet a controlled movement must be ensured to keep the crane balanced.

Types of Crane Machines

There are several types of cranes, and all of them are classified depending upon the nature of the work they have to perform. We will discuss nine types of cranes with their complete details. The types of cranes are given as follows:

- Bulk Handling crane

- Stacker crane

- Tower crane

- Telescopic crane

- Vehicle-mounted crane

- Rough Terrain crane

- Crawler crane

- Floating crane

- Aerial crane

Bulk Handling Crane machine

As the name suggests that this type of crane deals with the transport of materials in bulk. These cranes can move materials like coal and other minerals more easily than any other crane.

- Bulk handling cranes are used at extraction as well as loading sites. Its carrier and hook are far bigger than any other cranes.

- Thermal power plants use this kind of cranes to move coal to the burning furnaces.

- Its hook and carrier design enable it to work properly.

- Its balance is exemplary and is focused on its four bases for bases.

- On harbors, these cranes empower easy unloading of the cargo ships.

Stacker Crane Machine

Stacker crane offers its services to the industries. It is an automated crane used in industries, more specifically, their depots or distribution centers.

These cranes use their carrying capacity to align and maintain the status of products before getting themselves dispatched.

- Stacker cranes use electric power to enforce mechanical structure to pick up loads carefully and stack them over each other to make room for the upcoming batch of productions.

- Another important character of the stacker that makes it unique and more effective is that it is lightweight, easily movable, and small. These qualities make it an inevitable carrier in the industrial world.

- Not only industries but also civil aviation takes complete advantage of the Stacker crane.

- It helps carry passenger luggage from the luggage section to aircraft and finds its application in unloading passenger’s luggage from aircraft.

Tower Crane Machine

One of the most common types of crane is the tower crane; it has been discussed in detail in the previous passage. Tower cranes are used in the construction of tall buildings.

- These types of cranes can be up to 265 feet with an arc radius of 230 feet. Its capacity of weight carriage is about 20 tons.

- Tower cranes are kinds of cranes mounted on concrete but are strictly tended on ground level from their base.

- It is anchored to the ground using anchor bolts, which hold the crane while lifting heavy loads.

Telescopic Crane Machine

Telescopic crane, a splendid machine with wonderful applications and specifications, finds its implementation in extraction and construction sites.

- Telescopic cranes use hydraulic power to take the central weight carrier to different lengths, increasing its work domain.

- It is a mobile crane and can move over various surfaces.

- Its supporting engine and suspension design make it an engineering wonder making its presence felt in almost all fields.

- Telescopic cranes work on hydraulic mechanisms supported by the internal combustion of their vehicles.

Vehicle Mounted Crane Machine

As the name suggests, these cranes are moveable types of cranes. Vehicle-mounted cranes are mobile and are temporarily structured.

- Vehicle-mounted cranes have a severe advantage that makes them a single step ahead of tower vehicles, which is their cost-effectiveness.

- These cranes do not require any extra equipment for their operation.

- It works very simply with the vehicle’s body acting as a base while the crane moves vertically upwards.

- Extension of outriggers horizontally from the trucks provides the necessary stabilization.

Rough Terrain Crane Machine

A rough terrain crane is another type of mobile crane. These types of cranes can easily encompass them over many complex kinds of surfaces. Rough terrain cranes are placed over a body with four compact rubber tires that allow climbing over uneven ground and necessary adhesion to the surface.

- Rough terrain cranes can get in the more compact places due to their compactness at work.

- Like vehicle-mounted cranes, these cranes also have outriggers to help themselves get stable.

- Another essential advantage of this crane is that it provides space for other site equipment acting as a pick reducing the work time, which helps in the immediate setting of the worksite.

Crawler Crane Machine

Crawler cranes are the crane types mounted on an undercarriage with a set of trucks or crawlers.

These trucks provide required stability and mobility, and Crawlers transform the toughest and complicated tasks into more accessible subjects to undertake.

- The crawler crane has a weight carrying capacity of about 50 to 300 tons.

- Another advantage of the crawler is its adaptable design with no outriggers.

- But crawlers are not fixed cranes and need to be assembled and disassembled when necessary.

Floating Crane Machine

Floating crane machines are also referred to as crane vessels or crane ships. These floating cranes can be implied at work sites such as oil rigs in the aquatic surroundings. It is a highly resistive crane mechanism reducing external force burden as experienced by its body. Its property of keeping itself intact places it high among the engineering world.

- This crane dates back to the middle ages, and with further technological advancement, it has helped ages in development.

- Projects on the sea and the highly precise nature of works are key traits of floating cranes, making them unique carrier equipment.

- It also uses the same mechanical and hydraulic mechanism supported by the body of the carrier.

- It can easily be moved to the site but requires highly professional personnel to make it effective and durable in aquatic surroundings.

Aerial Crane Machine

These crane machines are not typical but are different as they are helicopters used exclusively to lift hefty loads. These cranes are helpful in cases where conventional cranes do not work. Risk relief programs and disaster mitigation are the places where their cranes practically come into action.

- These are some types of cranes, and all types are not discussed here because there are several hundred types of cranes, and it is practically impossible to explain all of them in a single article.

- Different crane types are also used inside manufacturing plants to assemble equipment.

- Over-headed cranes that move along beams are used to lift loads in manufacturing plants. To load trucks and railway vehicles, a side lift is used.

Applications of Crane Machines

- Tower and other large-span cranes are used at construction sites to help shift the load, whether an object like a wall rendering machine or construction material like cement, sand, or reinforced steel.

- Vacuum lifters are used with our mini cranes to install glass facades on buildings, homes, or skyscrapers. Where requested, these cranes can install and repair the stuff like glass windows of a considerably high building.

- Lightweight mini-cranes can be placed on top of roofs and ceilings to carry materials from the ground. Low ground pressure exerted by the tracks and platforms to expand the load distribution through stabilizers makes it possible for a lightweight crane to lift a load.

- Mini cranes can be used to lift steel frames both inside and outside of small and large facilities. The operators particularly appreciate the pick and drop method of these cranes

- The flexibility, lightness, and adaptability of mini cranes allow performing any construction work. Airports, large construction sites, mines, railways, stadiums, and public work are examples of sites considered practical sites for cranes.

- A residential area also requires some particular types of cranes that can suit them. We know the residential area is a more sensitive place, and slight negligence can cause several losses. In these areas, small cranes can carry equipment and even install glass windows by attaching suction cups on mechanical arms.

- Large span cranes are used for the installation of prefabricated homes. These cranes can carry wooden logs to be placed rightfully to assemble houses.

- If we get ourselves into the world of wood supply, we will know that it will be very time-consuming to carry wooden logs by a human being. So cranes then take charge and can easily lift several logs simultaneously and load them onto the vehicles.

- Cranes can be used in industries for carrying several types of equipment. Material handling is an industrial application of cranes, and the pick and maintain the function of cranes enable them to help keep several industrial units.

- Some cranes are built to perform because they have to deal with far more sensitive and dangerous working locations such as the operational sites in nuclear power plants or thermal power plants.

- Transportation infrastructures can be repaired using small cranes that can access any narrow available space.

Every field and area could not be developed entirely if not exposed to any crane mechanism. In other words, we can say that it is almost impossible to perform any field task without using cranes.

Advantages of Crane Machines

- Large crane machines can carry a weight that has far more limits than a human can ever reach.

- Cranes can have the most stable mechanism to avoid spilling or wastage of any material being carried.

- Static cranes, when set up, can have a radius of about 50m.

- Some cranes can be fixed permanently to work on fixed ground level.

- Precision in load transportation is also a key advantage of cranes.

- Using cranes for any site ensures safety for nearby residents due to the extreme accuracy of crane transportation.

- The height of some cranes can be adjusted according to requirements.

- Rescue operations also require cranes to be operational due to their high approach and weight management.

- Cargo embarking and disembarking can only take place in the presence of cranes.

- Mobile cranes can transport as well as improvise to get the job done.

- Cranes can be used for multi-purposes, making them the essential machinery for human beings.

Disadvantages of Crane Machines

- Sometimes, cranes are costly and utilize a lot of time and money to be shifted from one place to another.

- The high cost of maintenance for depreciation and repairs makes companies be at various losses.

- Laborer management is another disadvantage of cranes.

- Cranes are challenging to set up and even more difficult to pack up.

- When used for mega processes or projects, large cranes can reduce the operating speed for that site, and all places that cannot afford a new one have to wait for the project to be completed.

- Large cranes affect the working process of any site, thus increasing the time for completion of the task.

- Mobile cranes are not allowed to travel along with regular traffic.

- The lowered boom of the cranes traveling on the road can reduce the sight of the driver resulting in an accident

- Movable cranes are not allowed to hire for a more extended period.

- Overloading can cause severe losses and accidents.

- Some cranes are far more expensive and technical to use; these cranes are operated by certified personnel who charge a lot, making the site work more challenging.

- Some cranes cannot rotate even when they have to.

- Poor management and inexperience usage of the cranes can lead to the destruction of residential and commercial sites.

- Cranes sometimes reduce the available space occupying a large area, thus reducing the open space for other machinery and equipment.

- Replacement of the cranes can cause severe issues for the owners. In the case of warranty, strict policies of vendors cause a lot of collateral loss to the client.

Conclusion

We have looked through every portion of cranes usage, its types, and even work mechanisms. What can we make of all of our research? Are crane machines useful or useless? Are cranes a relief or headache? Should we switch to cranes if there is site work? We can answer all these and other questions with only one statement: it is inevitable for every construction or working site involving heavy materials to have at least one crane on-site, but remember safety is utmost.

Moreover, if we look through the advantages and disadvantages of cranes, we have more potential benefits than disadvantages. Not only construction sites but also industries, power sector, rescue missions, and warfare, every field has been at an advantage after developing this particular technology. It was initially created for construction only, but its evolution over time made it an overall package. It has become one of the essential types of machinery or technology being used today.