Let’s explore different Types of Laser Cutting Machines! Material cutting is one of the most fundamental steps in the industry. There’s no denying the fact that throughout history, numerous methods have been used to cut materials to create the final project. However, as the technological world has progressed, advanced methods have taken over, such as laser-cutting machines.

Laser cutting is not that old phenomenon, and is considered very effective too. As the demand for manufactured goods is increasing unimaginably all around the globe, laser cutting stays one of the top-notch options. Here’s what you need to know about laser cutting technology and its types;

What are Laser Cutting Machines?

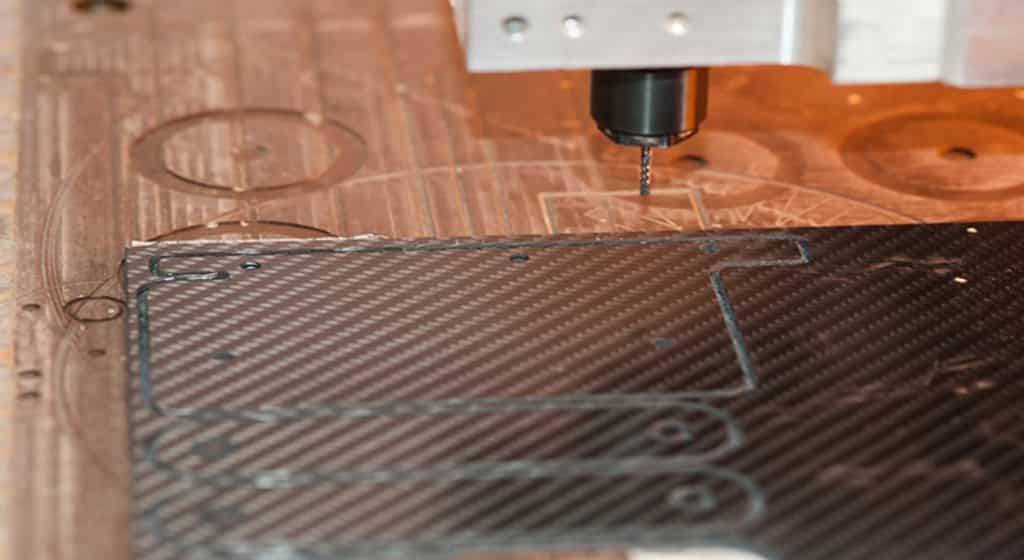

It is a non-contact process where a beam of laser is used to melt and cut down the material. The beam of light is responsible for creating tremendous heat and pressure which helps cut through some of the hardest materials as well. The best part about laser cutting is that it’s super precise and effective.

The focused laser beam is very thin and invisible. Laser is often used to cut through the material but it can also be used to create a pattern or any kind of design on the material too. Apart from making logos, and designs, there is also tube cutting laser machine which is best for cutting pipes and tubes.

which is best for cutting pipes and tubes.

Type of Laser Cutting Machines

Let’s explore various Types of Laser Cutting Machines along with its basic details!

along with its basic details!

Fiber Laser Cutting Machine

One of the most used machines is the fiber laser, which uses the seed laser and is also part of the solid-state laser group. Unique glass fibers are used to enhance the capability of the beam. The wavelength of the lasers is 1.064 micrometers which give it a relatively small focal diameter and this is why these machines are considered some of the most expensive in the market. The best part about these machines is that they are maintenance-free and can provide about 25,000 laser hours without causing any trouble.

Moreover, these machines are also known for producing much stronger and more stable beams. The lasers are usually in a continuous beam but if you want to change the option, you have a pulsed setting as well, depending on the use. Fiber lasers can work with metals as well as non-metals such as wood, plastic, and even glass. These lasers are considered some of the most versatile as they can work with numerous materials. If you are planning to work with thin materials, fiber lasers are the best option available.

CO2 Laser Cutting Machine

The infamous CO2 laser cutters produce light beams by using electricity through a mixture of gas in a filled tube, and the tube is filled with mirrors. Most of the mirrors are partially reflective, but there’s one mirror that is fully reflective as it allows light to pass through. When it comes to the gas mixture, it is usually a blend of carbon dioxide, nitrogen, helium , and hydrogen.

, and hydrogen.

The lasers from such cutters produce invisible light and can range up to multiple kilowatts of given full power. The wavelength of CO2 lasers is 10.6 micrometers and it is used commonly for materials such as wood and paper. Some industries use it to work with acrylic plastics as well as leather and fabrics. Food industries make use of CO2 lasers as well for processing food items such as chestnuts and cheese.

as well as leather and fabrics. Food industries make use of CO2 lasers as well for processing food items such as chestnuts and cheese.

These machines are best for non-metallic materials, only a few types of metals can be used, such as aluminum. If you are planning to boost the power of the CO2 beam, it is essential to increase the oxygen content. Yet, only experts can perform this action.

Crystal Laser Cutting Machine

Crystal laser machines have some of the highest cutting powers as these machines generate beams from Neodymium doped yttrium orthovanadate. As the wavelength of this laser is smaller when compared to CO2 lasers, it is capable of cutting through thicker materials and is often used in heavy industries. Smaller wavelength is responsible for better cutting capability along with enhanced focus. However, these machines are used for high-power functionality and this is the reason that their parts expire pretty soon, and these machines are super expensive as well.

Crystal lasers are used for a huge range of applications, especially military. These lasers are used for materials such as metals, ceramics , and plastic.

, and plastic.

Conclusion

Laser cutting machines are widely used in the manufacturing industry as they are tremendous for cutting large pieces of materials. This technology provides high-quality cuts with tremendous finishing and as it is a non-contact process, there’s nothing to worry about when it comes to surface blemishing. You can cut simple or complex parts using laser cutting machines and this is the reason many industries are becoming more inclined towards this use of this technology to upscale their business.