What is temperature? or How do you measure the temperature? Any idea! In this article, we will learn all about temperature and its measurements along with the definition, meaning, various scales, etc. Let’s explore!

What is Temperature? Definition & Meaning

Temperature Basics

Temperature measurement is significant in food, pharmaceutical, oil, gas, beverage, and power industries. It is critical and needs accuracy to ensure the proper functioning of plants.

Apart from this, temperature measurement is part of almost everything in our everyday lives. From data loggers to probe thermometers and monitoring weather, we cannot neglect its importance.

- It is needed in hospitals as well for calculating body temperatures.

- It is recorded on devices called thermometers.

Temperature Meaning

The term comes from the Greek words “thermos” (meaning hot) and “metron” (meaning measure). There are various types of thermometers constructed uniquely and are based on specific working principles.

Several different temperature measuring methods are devised for recording temperature on devices like thermometers or sensors.

Temperature Definition

Temperature is defined as the extent of hotness or coldness of a body expressed on a definite scale.

- It’s a scalar physical quantity that indicates heat flow from a hotter body to a colder body.

- Temperature is an intensive property (which means not dependent on the quantity of matter in consideration).

Scales of Temperature

If you want temperature measurements, you should know the different scales of temperature. The most popular temperature scales or temperature units are discussed below.

Fahrenheit

It is used in the United States and some other English-speaking countries. It was invented by an 18th-century German Physicist named Daniel Gabriel Fahrenheit in 1724.

- At that time, he selected the values of 30 for the freezing point of water and 90 for normal body temperature.

- They were changed to 32 and 96 later on.

- However, the latter value was revised to 98.6. The interval between two values is divided into 180 equal parts.

- Fahrenheit is represented as °F.

The conversion of temperature in Celsius or centigrade to Fahrenheit needs the following conversion formula:

°F = (9/5 × °C) + 32

Fahrenheit temperature unit was common in all English-speaking countries during the 1970s, but later on, many countries adopted the Celsius scale.

Celsius

Celsius scale, also called the centigrade scale, was invented in 1742 by Anders Celsius, a Swedish Astronomer. Celsius temperature unit is adopted for everyday use in almost all countries and is widely used in sciences also.

- It is a derived unit in the SI.

- The scale is divided into hundred equal parts. It is based on 0° and 100°, the freezing point and boiling point of water, respectively.

- In the beginning, Celsius used 0° to represent boiling point and 100° for representing the freezing point of water, but now it’s reversed.

- Celsius is represented as °C.

The conversion formula for converting temperature in Fahrenheit to Celsius is:

°C = 5/9 (°F − 32)

Kelvin

Kelvin is the base unit of thermodynamics in the International System of Units for the measurements of temperature.

- It is a standard scientific measurement scale.

- The representation for Kelvin is “K.”

- The final zero i-e zero points of the Kelvin scale is equal to −273.15° on the Celsius temperature scale and −459.67°on on the Fahrenheit temperature scale.

- Absolute zero is the theoretical temperature at which the molecules of a substance have the lowest energy; therefore, all the values on this scale are positive.

Kelvin and Celsius degrees have the same magnitudes because the difference between boiling and freezing points of water is 100 degrees on both scales. Kelvin scale is the international standard scale for the measurement of temperature. It was invented by Lord Kelvin.

Rankine

Rankine is represented as °R or °Ra. William Rankine invented it in 1859. The reference point is 0°R. The size of one Rankine degree is the same as Fahrenheit. The freezing point of water according to this scale is 491.67°R.

This temperature unit was used in some technology fields in the USA, but NIST doesn’t recommend it, so it is not widely used nowadays.

Reaumur

Reaumur is represented as °Ré or °Re. It was first introduced in 1730 by Réne de Réaumur.

- The scale is based on two points, 0°Re and 80°Re, representing freezing and boiling water points, respectively.

- It was used in Europe and Russia during a period, but it lost its importance in the last century.

Measurements of Temperature

There are four major types of temperature measuring devices. They use different temperature measuring methods based on their working principle. The devices are:

- Mechanical devices

- Thermojunctive devices

- Thermoresistive devices

- Radiative devices

We will learn all devices one by one to clear our basic concept on temperature measurements.

Mechanical Devices for Temperature Measurements

They include liquid-in-glass thermometers, bimetallic strips, pressure, sealed bellows, and bulb and capillary sensors.

Working principle

They are based on the principle of mechanical motion. Whenever heat is given to a substance, it expands. The value of temperature is then recorded from the scale on the instrument. Mechanical devices may consist of liquid, solid, or vapors as temperature-sensitive matter.

Liquid-in Glass Thermometers

Construction

It constitutes:

- A bulb acts as the container for the liquid in the thermometer.

- A glass tube with a small capillary connected to the bulb.

- A temperature scale for recording values.

- Point of reference or calibration point present right above the bulb. It represents the ice point.

- A temperature-sensitive liquid, either mercury or any other alcohol substance.

- An inert gas is filled above the mercury. It may be argon or nitrogen.

Working

- The working principle is heat causes expansion.

- An increase in temperature will cause the liquid to rise.

- The liquid, either mercury or any other alcohol substance, moves up the tube.

- Temperature is recorded through the scale present on the instrument.

Advantages

- It is cost-effective.

- It is handy to use.

- They do not need the power supply for charging like the electrical thermometers.

- Their repeatability is good, and the calibration stays unaffected.

Applications

- They are widely used in medicine, metrology, and industry.

- They have oceanographic applications too.

- They are employed in different configurations in the navy and marine corps.

- They are also used in households.

Limitations

- They are not effective in being used at very high and low temperatures.

- They don’t provide highly accurate results.

- They are delicate, so it needs a lot of care to handle them as they may break.

- The results provided are not digital (as in electrical thermometers); therefore, they are limited to households.

- The temperature measured must be recorded right away because it is affected by environmental conditions like temperature.

- Human eyes record readings, so it needs concentration and good eyesight.

- The temperature can only be recorded in Fahrenheit or Celsius. Conversion is needed if the temperature is required in other scales.

- Temperatures ranging between -200 and 600 degrees Celsius can be calculated using liquid-in-glass thermometers.

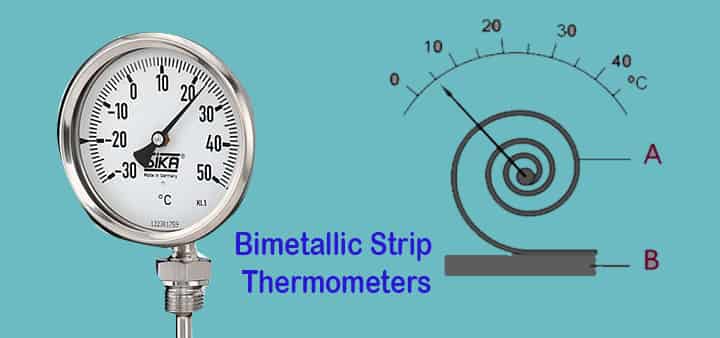

Bimetallic strip thermometers

Let’s see the construction, working, advantages, applications, limitations of Bimetalluic strip thermometers.

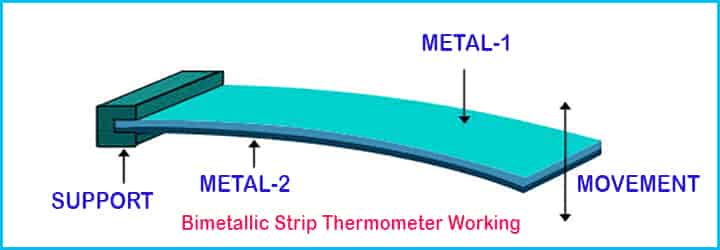

Construction

- It has two metallic strips. Both are made of different metals.

- The working of bimetallic strip thermometers is based upon thermal expansion properties and the coefficient of thermal expansion of metals.

- One metal has a smaller coefficient of thermal expansion than the other.

- Both the strips are fixed at one end and free at the other end.

- Different metals such as steel and invar, steel and copper, steel and brass, etc., are coupled together.

Working

Let’s see the basic working principle,

- It works by converting the temperature change into mechanical displacement.

- The working of bimetallic strip thermometers is based upon thermal expansion properties and the coefficient of thermal expansion of metals.

- When temperature increases, one strip will expand more than the other, causing the pair to bend towards the free end. The strip will bend towards the direction of the metal, having a smaller coefficient of temperature.

- When the temperature decreases, the strip bends in the direction of metal with a high-temperature coefficient.

- The bending motion is connected to a thermometer dial.

Advantages

- They don’t need a power supply.

- They are cheaper.

- They are simple and durable.

- They are based on robust design.

- It is utilized for a wide range of temperatures.

- They give a linear response to a change in temperature.

- Maintenance and installation are quick and easy.

- They don’t need a power source to operate.

Applications

- They are used as wood burner thermometers or oven thermometers.

- They are widely used in thermostats of air conditioners.

- They are used in industrial devices like heaters, hot wires, and refineries.

- They are used in control devices and oil burners also.

Limitations

- They are not suitable for very low and very high-temperature measurements. The temperature range is 40-80 °F.

- They are less accurate.

- Due to manual reading, they are best to be used at homes only.

- They require frequent calibration.

- If they are handled roughly, calibration gets disturbed.

Pressure Thermometers

Let’s see the construction, working, advantages, applications, limitations of pressure thermometers.

Construction

It consists of:

- A bulb (connected to measuring device by a capillary tube)

- A capillary tube

- Bourdon tube (made of a hardened chromium-molybdenum alloyed steel)

- Arrangement for measuring (calibrated scale with a pointer)

- Linking and gearing mechanism

Working

- Pressure thermometers work on the principle of thermal expansion.

- Temperature measurement takes place indirectly by measuring pressure.

- Instead of liquid or solid, it works by the expansion of a gas. However, some use liquid also instead of gas.

- The bulb is introduced into a medium whose temperature needs to be measured.

- Now, The pressure in the bulb increases or decreases due to the difference in medium and environment’s temperature.

- The pressure change is transmitted to the bourdon tube, which happens through the capillary tube.

- The pointer changes position on the calibration scale. This pressure change is used to indicate the temperature change.

Advantages

- They are simple to use, and the readings can be directly recorded.

- They are not costly.

- Capillary tubes up to 60m can be used.

- They operate successfully and have a high accuracy

- They are sensitive and don’t need much maintenance.

Applications

- They are used in industrial equipment, boilers, compressors, piping

, etc.

, etc. - They are also used in finding the outside temperature from inside of the building.

Limitations

- They have limited linearity, and there are more chances for errors.

- Sometimes the bulb is too large to fit in the space.

- The maximum temperature is way too limited as compared to electrical thermometers.

- Calibration drift and error caused due to filling the tube.

- The temperature range is limited. Usually -80 to 400 °C.

Thermo-Junction Devices or Thermocouples

Construction

- They are constructed by joining two different metals together that produce a voltage with a temperature change.

- Any two dissimilar metals can be used to construct thermocouples.

- While selecting two materials, an important factor is a thermoelectric difference between the two materials.

- The junction of two metals is termed a sensing junction.

Working

- When metals are connected, voltage is generated at the junction. This voltage is called thermos junction voltage. This effect is known as the “Peltier Effect.”

- When the temperature changes at the junction, the voltage also changes. It is measured by the input circuits of the electronic controller in thermocouples.

- The output voltage is proportional to the temperature difference between free terminals and junctions. It is called the “Thompson Effect.”

- The voltage is measured when the reference junction is kept at a known temperature. At this time, the temperature at the sensing junction is deduced.

- The generated voltage is proportional to the difference in temperatures. This combined effect is known as the “Seebeck Effect or Thermo-junction Effect.”

Advantages

- The readings are consistent.

- They are capable of measuring a wide range of temperatures.

- They have linearity.

- They have an accuracy of 0.05%.

- They are inexpensive and constructed easily.

- They function in a broad range of temperatures and can be inserted in difficult points.

Applications

- Kilns and autoclaves use thermocouples.

- They are used for controlling the temperatures of space crafts, airplanes, and satellites.

- Many thermocouples connected create a thermopile. It produces a large amount of voltage as compared to a single thermocouple.

- Thermopiles can be used for the detection of infrared radiations.

- Thermopiles can also generate power for space probes.

Limitations

- They have low sensitivity as compared to RTDs and thermistors.

- At room temperature, the output of thermocouples is as low as 0.001 volts.

- There are different types of thermocouples. Each of them has its formulas for the conversion of voltage into temperature. These equations are quite complex.

- They are subjected to corrosion due to contact of two dissimilar metals, which can affect calibration and accuracy.

- They require maintenance for good long-term performance.

Thermo-Resistance Temperature Measuring Devices

Thermo-resistive temperature measuring devices include RTDs (resistance temperature detectors) and thermistors.

Resistance Temperature Detectors

Let’s see the basics of resistance temperature detectors along with construction, working, application, advantages, limitations.

Construction

- It is made of a small or long diameter wire wound on an etched grid or a coil on a substrate, just like a strain gage.

- The most common type of metals used in RTDs is BALCO wire, copper, or platinum.

- The bridge circuit consists of three known resistances R1, R2, AND R3 (variable), an unknown variable resistor, a voltage source, and an ammeter in RTDs.

- There is another type of construction known as Wheatstone bridge circuit or two-wire RTD bridge circuit. It is a quarter bridge circuit.

Working

- It is based on the principle that electrical resistance changes linearly with a temperature change.

- They have a positive temperature coefficient.

- The element at base temperature has resistance directly proportional to the length of the element and inversely proportional to the cross-section area.

- An electrical circuit is present that calculates the change in RTD resistance, which is used to calculate the temperature change.

- Resistance of RTD rises with a temperature rise.

Advantages

- They have a linear resistance to temperature.

- They are stable.

- They can perform well over a wide range of temperatures.

- Their accuracy and stability are replacing thermocouples.

- They have high repeatability.

- They have high precision and are mostly used instead of thermocouples in a temperature range up to 600 °C.

Applications

- They are widely used for sensing liquid and air temperature in ducts and pipes.

- They are also used in power electronics, consumer electronics, medical electronics, food handling, processing, etc.

- RTD sensors can measure the engine temperature.

- They have applications in the military, aerospace, and computer also.

- They are present in appliances like coffee machines and cell phones.

Limitations

- They are vulnerable to self-heating.

- They are not very responsive.

- An external circuit power is required to operate.

- Lead wires connecting RTD to the controller can add up to the total resistance of connected RTD. It can cause errors and inaccuracy in temperature measurement.

- They can function at a temperature ranging from -200 to 600 °C. Above this range, It is not the best fit.

- Installation of RTDs is complex and requires experience.

- It is costly as compared to thermocouples.

- It’s difficult to insert thin film RTD elements in small diameter MI cables.

Thermistors

Thermistors are semiconductors that undergo a greater change in resistance over a small range of temperature. It has two types; Positive temperature coefficient (PTC) and Negative temperature coefficient (NTC). NTCs are more commonly used for the measurement of temperature. Temperature and resistance are proportional in PTC and inversely proportional in NTC.

Construction

- Thermal resistors or thermistors are similar to RTDs, but instead of metal, a semiconductor is used.

- They are made up of oxides like manganese oxide, nickel oxide, cobalt oxide, copper oxide, titanium oxide, lithium oxide, etc.

- These oxides are combined in specific proportions.

- They are compressed into required shapes. They are recrystallized by treating them with heat. They are formed into dense ceramic bodies with specific resistance temperature characteristics.

- They come in several sizes and shapes like bead type, disc type, and rod type.

- When greater power dissipation is required, the best options are rod type and disc type.

- Bead type is the smallest in configuration among all. It has a diameter of 0.15mm.

Working

- It is based on the principle of varying resistance due to temperature.

- An ohmmeter calculates the resistance. It is linked in series with the battery and the meter.

- The change in resistance is dependent upon the material used in the construction of the thermistor.

- Thermistors are known to be resistors that limit the amount of current in the circuit. But since it’s a thermal resistor, the change in resistance depends on the temperature change.

- Its temperature rises, the resistance of these resistors decreases in the circuit, which is dependent on the coefficient of temperature.

Advantages

- They are more sensitive than RTDs.

- They have high stability and are responsive.

- They are compact and cheap.

- Its main purpose is to maintain the amount of resistance in the circuit to minimize the effects of temperature.

- They can function over a small range of temperatures.

- They are smaller in size and fit in even the small areas.

- They are compatible with many devices because of the two-wired connection.

- They are easy to use and can be customized.

Limitations

- They cannot be used for high-temperature measurement. The maximum range is 100 or 200 °C sometimes.

- The excitation current is low to avoid self-heating.

- Shielded power lines are filters that will be needed due to high resistance.

- Resistance vs. temperature characteristics has non-linearity.

Applications

- In digital thermometers, they can be used as temperature sensors.

- They are used in automotive industries to check the temperature of coolant and oil in vehicles and trucks.

- It is used in household appliances.

- They are circuit protection devices.

- Thermistors are utilized in circuits of Wheatstone bridge, rechargeable batteries, and electrical devices, etc.

Radiative Temperature Measuring Devices

They include two types of devices; infrared pyrometers and optical pyrometers.

Infrared Pyrometers

If I ask you, what kind of instrument is widely used for temperature measurements of objects? Simple! Infrared pyrometers!

They are non-contact temperature sensors that are used to measure the temperature of objects.

Working principle

It is based on the principle that the amount of energy emitted by objects is the function of their temperature. It measures the temperature by determining the intensity of energy given off by the body.

Advantages

- They don’t make contact with the measuring body, unlike other devices.

- They are useful when the target is inaccessible or too hot that it can damage the instruments.

- They are a good option for surface measurements.

- They are compact and lightweight.

- There is no need to shut down systems for performing diagnoses.

- They are suitable for industry or regulatory requirements.

Applications

- They are suitable for measuring the high temperature inside combustion chambers of gas turbines.

- They are used in salt bath furnaces.

- A hot air balloon has an infrared pyrometer inserted at the top to avoid overheating of fabric.

- They are also present in steam boilers.

Limitations

- They are only used for solid objects, not gas or liquid.

- They are quite expensive.

- Accuracy also varies, depending on the model.

Optical Pyrometers

If I ask you, what kind of instrument is widely used for high temperature measurements? Simple! Optical pyrometers!

They are beneficial in measuring very high temperatures (even flames).

Working principle

They use infrared radiation-sensitive sensors like photoresistors or photodiodes to compare the unknown radiation with the radiation from an internal incandescent source.

Advantages

- They are sensitive to infrared radiation.

- It has higher accuracy.

- Quite useful in high temperatures

- They measure temperature without contact with the object.

- They are used for measuring the temperature of moving and distant bodies.

- It has good accuracy and is lightweight.

Applications

- They are utilized in the smelter industry and metallurgical furnace operations.

- The combustion temperature can be measured in a blast furnace by optical pyrometers.

- They are fitted in gas turbine engines to measure the temperature of turbine blades.

Limitations

- Smoke and dust can affect accuracy.

- It is costly.

- There are more chances of human errors.

- They are not fit for measuring the temperature of clean gases burning and do not radiate visible energy.

Conclusion

Hence, we have got a detailed understanding of what is temperature, its measurements, types, various measuring scales, etc. Any questions, please let us know!

Hello my family member! I wish to say that this post is awesome, great written and include approximately all vital infos. I¦d like to look extra posts like this .

Whats up very cool blog!! Man .. Excellent .. Wonderful .. I will bookmark your site and take the feeds also?KI’m satisfied to find so many helpful info right here within the submit, we’d like work out extra techniques in this regard, thank you for sharing. . . . . .