In this article, we will learn what is V8 engine in cars along with parts, common problems, applications. Let’s explore the V8 engine!

What is V8 Engine in Cars?

V8 Engine Basics

The invention of engines provided us massive benefits, which makes humankind capable of doing numerous things. These chores are pretty essential and helped this invention attain one of the most important inventions. Some engines are classified based on cylinders.

- These engines are equipped with different cylinders that provide them power-packed operations.

- The requirement of engines is as per the automobile shape and size.

- The V8 engines are among the engines which are capable of delivering effective power to the same.

History of V8 Engine

The history of V8 Engines starts in 1904. Leon Levavasseur is the inventor of the V8 engine and he started this by building an Antoinette engine.

engine.

- The engine was used in speedboats in 1904.

- Later on, Renault & Buchet was started to use in commerical production by introducing in racing cars & aeroplanes.

Here, we will discuss the V8 engines and their work with all the components and their elaborative analysis. It will provide us important insights into the application of the V8 engine as well. With this information, we can easily help ourselves to equip with all the knowledge regarding the same.

Some numerous vehicles and machines require just one cylinder, but the automobiles like trucks and heavy cars specifically need those engines capable of providing massive horsepower.

Definition of V8 Engine Cars

Before understanding the concept of the V8 engine, it is pretty essential to understand the internal combustion engine with numerous cylinders.

- It is quite evident that all the cylinders inside an engine remain at the same size.

- The automakers just alter the number of the cylinder in different rows. Some use it in single rows, and some use it in two rows in a V-like shape.

- This set-up is quite common and used in most engines where there is a need to fit more cylinders in minimal space.

- When this set-up uses 8 cylinders, then it is known as the V8 engine.

After getting the idea of cylinders now, it’s time to understand the core definition of the V8 engine. The V8 engine is an eight-cylinder engine equipped with a water-cooled unit with cast cylinder blocks and heads.

equipped with a water-cooled unit with cast cylinder blocks and heads.

- It is equipped with two banks of steel cylinder liners specifically pressed down and set at an angle of 90degree to each other.

- In this, the crankshaft is being carried out with the main five bearings.

- The crankshaft is located at the center, and an inverted tooth chain drives explicitly.

- In these, the valves are being operated with the help of hydraulic tappets, pushrods, and rockers.

Parts of a V8 Engine

There are numerous components available in a V8 engine that should be given preference to understand the V8 engine working and the functionality.

Lubrication system

The lubrication system is among the effective Parts of a V8 Engine that play a pivotal role in the engine’s functioning. In this, the oil pump is responsible for drawing the oil from the oil pan.

- It forces the same through the filter into the crankshaft passage, which goes through the connecting rods and passes through rings and pistons.

- In this, the oil is pushed along the pushrods and lifters and keeps a check on rocker arms.

- It will flow down to effectively completing the cycle.

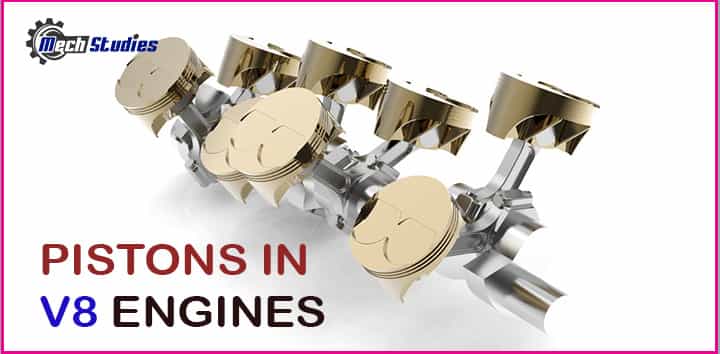

Piston

The piston is among the energy conversion parts of the engine that effectively converts the fuel’s potential energy into kinetic energy.

The kinetic energy helps in turning the crankshaft. The piston is effectively a hollow cylindrical-shaped part that moves up and down inside the engine’s cylinder. It is equipped with a groove around its perimeter on which the rings are placed for grip.

- The piston fits in the cylinder with clearance.

- The function of rings is to provide airtightness when it attaches to the cylinder.

- The piston motion has four strokes for completing its one cycle.

- The first stroke is known as intake stroke, and it helps fill the cylinder with air and fuel mixture.

- After the first stroke, just before the piston reaches the maximum height of the cylinder, there is the ignition with the help of the spark plug’s firing.

- This is the second stroke, and it advances with the third stroke, also known as the power stroke. This stroke is responsible for powering the engine. The fourth and the last stroke is only for sending out the burned gases through the exhaust system.

Aluminum is among the common metals used for manufacturing pistons due to its property of being a lightweight and excellent conductor of heat. Pitons are the component that is responsible for numerous functions.

- It transmits the driving force of combustion towards the crankshaft and causes the crankshaft to rotate.

- It also acts as a dynamic gas-tight plug that keeps the combustion of the cylinder.

- Apart from those, it also provides functions of bearings for the small end of the rod.

Wrist pin

The wrist pin is the component that helps in connecting the connecting rod and piston. Through the piston, the connecting rod comes up. The wrist pin is then inserted into the a-hole that effectively goes through the piston side at which it is connected to the rod.

Piston Head

The piston head is also known as the crown, and it is the top surface. It lies against the exerted explosive force due to ignition.

- It can be of different structures such as concave, convex, or flat.

- This also has various shapes that help in controlling the combustion process.

Timing belt or timing chain & Camshaft

The V8 engine has an effective component that is known as the timing belt.

- These are made of metal, quite flexible, and have the core function of rotating the camshaft.

- The crankshaft is driving it.

- It is also used to provide a time for opening and closing the valves in the V8 engine.

- In the V8 engine, the camshaft rotates for one rotation for every two rotations of the crankshaft.

The Cylinder Head

These are the matl part of the V8 engines that effectively covers the cylinders. These are attached to the top of the block and contain combustion chambers, valves, and water jackets.

- In this, the head gasket seals the opening within the head block.

- It also seals the cylinders.

Push Rods

This component of the V8 engine is attached to eh valve lifter to the rocker arm. The oil is pumped to lubricate the rocker arms and valves with the passage available in the center.

Flywheel

This component in the V8 engine is massively a large wheel that is attached to the crankshaft.

- It is used for providing the momentum for the crankshaft to turn without the effect of power.

- This is done by keeping some of the energy generated at the time of power stroke.

Subsequently, it uses a mere amount of energy that also helps in driving the connecting rods, pistons, and crankshaft. This operation provides smooth functioning of the V8 engine.

Vibration Damper

This component is also known as the harmonic balancer, which is connected for reducing the torsional vibration.

- In this, the operation starts when the cylinder fires and the power got transmitted by the crankshaft.

- In this, the front of the crankshaft takes the force of the power because of which it moves before the rear of the crankshaft.

- Twisting motion is attained due to this.

- The unwinding causes the torsional vibration, which has to be minimized. For that purpose, the vibration damper is used.

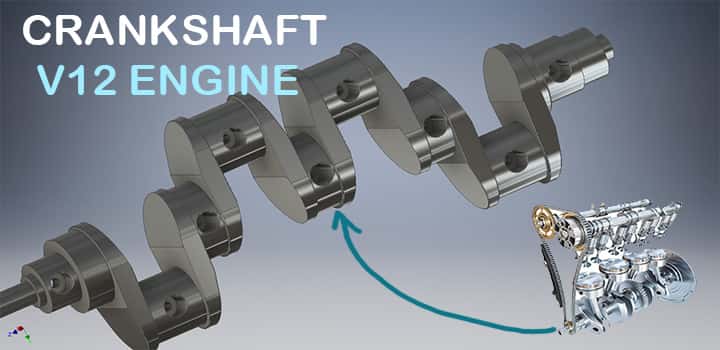

Crankshaft

The crankshaft is an important component for a V8 engine as it helps convert the pistons’ reciprocating motion into rotary motion. Ultimately it helps in providing the turning motion to the wheels.

- It just works like the bicycle pedals that convert the up and down motion to rotary motion.

- The crankshaft is specifically connected to the pistons by a connecting rod.

Main Bearings

The function of the main bearings is to help the crankshaft to be held in the specified place. The main bearings can be one or more than the number of cylinders. However, the number of the bearings is one less than the number of cylinders. The bearings help in supporting the crankshaft and also controls the forward and backward motion of the crankshaft.

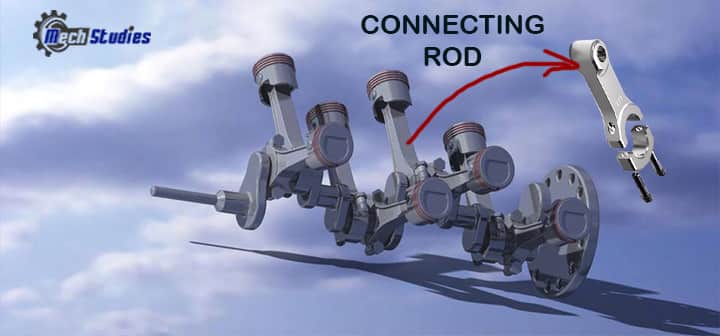

Connecting Rod and bearings

The linkage between the piston and crankshaft is attained with the help of connecting rod. In this, the top end has a hole in which the piston wrist pin is attached.

- The bottom end is attached to the crankshaft.

- These are made up of alloy steel and aluminum.

- The connecting rod bearings act as inserts attached to eh connecting rod’s bottom end and keep on riding on the journals, which are part of the crankshaft.

Oil Pump

The core function of the oil pump for a V8 engine is to forcefully pressurize the oil to the different parts of the engine.

- The common pumps used in these engines are rotary and gear.

- This part is equipped with driven spur gear and driving gear that is effectively attached to a shaft driven by the camshaft.

- These two gears are of the same size.

- The help of the camshaft drives the rotary pump.

Cylinder

Cylinders are the parts of a V8 engine with the shape of the round hole through the block, which is bored to receive the piston.

- Most automobile engines are air-cooled or water-cooled and having two-cycle or four cycles.

- These cylinders are arranged inline or V shape.

- These are core part that makes it quite efficient for the V8 engine.

Oil Seals

These are maybe the mere parts of the engine but holds massive functionality. Oils seals are generally metal composite and rubber items. They are commonly mounted at the end of the shafts.

- The core function of the oil seals is to act as a sealant for different liquids available in the engine, such as transmission fluid, oil, and power steering fluid.

- This helps them to be kept in a specific housing.

- However, the most probable components that are susceptible to leaking are the oil seals.

- The placement of oil seals is quite important, and it should be fitted with utmost care.

Oil Filler Cap

Oil filler caps are the plastic or metal cap specifically used to cover the opening into the valve cover. Numerous automobiles use this oil filler cap, and in some, the crankcase is vented through the oil filler cap.

Oil Filter

Oil filters are the essential parts used for straining abrasive materials and dirt out of the oil. These are not apt for removing those materials which are easily soluble with the oil. However, removing the solid materials doesn’t help in reducing the probability of acid formation.

- These grits are removed to reduce the wear on the engine parts.

- With the modification, the modern V8 engines are equipped with the full-flow type of oil filters.

- This is responsible for filtering all the oil before it passes to the engine bearings.

- However, when the oil filter gets clogged, the bypass valve helps continue oil towards the bearings.

Oil Pipes

There are numerous passages available in a V8 engine through which the oil is to be sent for the moving parts. These pathways are constructed for delivering ample pressure to fresh lubricating oil. If in case these pathways get clogged, then the different components will be locked together. If the flow of oil discontinues or stops, then it may cause problems for the engine.

- These are specifically drilled into the different connecting parts of the engine.

- These passages are for apt lubrication to the moving parts.

- The major components get lubricated and keep the engine away from defects that occur due to minimal lubrication.

Oil Pan

The oil pan is situated at the bottom of the crankcase, a container containing the blood for the engine.

- These are commonly manufactured of thin steel, and it effectively collects the oil when it flows down from the crankcase sides.

- The oil pan is shaped to have a deeper section in which the oil pump is situated.

- At the bottom of the pan, a drain plug is specifically used for draining the oil.

Serpentine Belts

This is one of the prominent parts of the V8 engine used for winding around all the pulleys driven by the crankshaft pulley. The modern design of the serpentine belts is apt for saving space. If it brakes, then the functionality of the drive comes to the stoppage.

How Does V8 Engines Work?

After the introduction here, we will discuss the core working of the V8 engine.

V8 Engines Working Principle

The operation of the V-8 engine has an effective procedure. The V-8 operated just like any standard gasoline-powered four-stroke engine. In this, the cylinder pulls the air and fuel and compresses the fuel and air in which a spark ignites the mixture and specifically creates massive power and forces that move the piston down, which ultimately results in the pushing out of exhaust gases as it travels to the backup.

Working Process of V8 Engines

In a V8 engine, the cycle takes place in 8 different cylinders at eight different times.

- In this, the cycle is dispersed out across the cylinder that ultimately provides smooth power delivery.

- The subsequent process in the operation of V8 engines includes the valvetrain.

- In this, the intake air comes from the top position of the engine and goes to the sides of the cylinder head.

- The cylinder is also an intake valve system that acts as a single exhaust valve for the engine.

- After this now comes the pushrods; this component works with the help of camshafts lobes.

- This activates the pushrods that help in the opening.

- In this, the camshaft, which is responsible for the operation of valves, is critically connected to the crankshaft.

- In this, for every two rotations of crankshaft, the camshaft rotates once.

- In this, the piston reaches the top position of the cylinder, which also counterbalances and provides a stagnant force.

Though the process sounds quite complicated, the entire process is quite simple and creates a flawless engine without any vibrations.

Pros of V8 Engines

The V8 id is among the common engines that provide effective performance. The configuration of these engines is based on performance. These are effective for most fo performance-oriented vehicles such as SUVs, racing cars, and trucks.

- The use of V8 engines massively gained popularity over the older engines.

- This is because of the compact and lightweight properties through which power it generates.

- The popularity of the V8 engine is because of its excellent torque and horsepower characteristics.

Structure of the V8 engine: The structure of the V8 engine makes the difference as it is an internal combustion engine equipped with a “V” configuration.

- In this, the pistons are aligned in as same as the structure of V.

- It acquires a 90-degree angle.

- The V8 engine effectively gains its whole power from the eight cylinders.

- Each bank is equipped with four cylinders.

- One of the most prominent benefits of the V8 engine is flexibility.

- It can be used as a compact or as large engine as per the application.

- It can be apt for sports coupe car.

When there is a need for a larger displacement form, it can be upgraded to provide maximum torque and be used for performance and load-carrying vehicles.

Smoother operation of the V8 engine: One of the most effective benefits of the V8 engine is its ability to provide a smooth finish in the running. This is because the V configuration allows the engine’s power strokes to take place closely and minimizes the vibration.

- V8 engines are capable of running smoother in comparison to other engine configurations.

- This is because the V8 engines producers power stroke at every 90 degrees.

- Due to this smoothness of the operation, there is less stress caused on the engine that helps in optimal performance and handling, making the driveability quite excellent.

Optimal balance of efficiency and performance: One of the major benefits of the V8 engine is its optimal torque generation and power output.

- When it comes to optimal power output, an eight-cylinder engine provides much more than any other 4 or 6 cylinder engine.

- Larger engine configurations are quite bulky and can provide the power output, but these are quite heavy, seriously dampers efficiency.

- V8 comes in between these, which makes it quite suitable for any kind of usage.

The V8 engine configuration provides effective return and can be suitable for those who want a relatively small and lightweight engine with an apt amount of balance in torque and power with optimal fuel economy.

Applications of the V8 Engines

The application of the V8 engine is quite vivid and can be used for different purposes. Here we are providing an all-around idea about the common applications of the same. Though the prominent usage of these engines is in the automobile sector, they can be used in different machines.

Automobiles: The prominent use of the V8 engine is in an automobile. It is being used in various kinds of trucks and cars. These are preferable for the most powerful vehicle segments in which luxury cars, muscle cars, pickup trucks, and SUVs come.

- Most car manufacturers equip their vehicles with a V8 engine as it is among the preferable engines.

- It is among those which is a specific sign of prestige and exclusivity.

- These V8s are made with series of modifications in which different components are modified.

- Some of the basic ones are offset crankpins which help in driving connecting rod pairs.

- It specifically helps in attaining a regular firing regime.

- The normal big-bore V8 engine, commonly used in most cars, is quite effective for those vehicles equipped with a front-wheel-drive system.

- The core applications are used in those automobiles: rear-wheel drive muscle cars, luxury cars

, light trucks, and sports cars.

, light trucks, and sports cars.

These engines are pretty good as they are equipped with narrower cylinder bank angles, cylinder bore spacings, and different ser of modifications that help reduce the space constraint of these automobiles.

In motorsports or racing cars: Though these engines are used in automobiles, the popularity of these engines comes through their usage in motorsports.

- In most automotive racing, these V8 engines are used with proper modifications.

- The most prominent and commonly known races in which these are used are Formula-1, NASCAR, etc.

- These engines are modified to result in uneven firing, which effectively helps in the engine tuning.

Economic trucks: V8 engines are also used in medium-weight trucks that makes them relatively simpler and maintenance-free.

- The larger V8s are effective for larger industrial types of equipment and long lorries.

- These are pretty useful for power-packed performance as well as practical functionality.

In aircraft engines: V8 engines were used commonly in aircraft, but modern light planes use modern ones equipped with flat-8 configurations.

- This is because it is easier to cool and lightweight.

- These are also used for those aircraft that use modular design components in world war II, where aircraft propulsion was an issue.

Conclusion

With all the information about the V8 engine, we will be equipped with almost all the information, but there are massive sets of data left that can help us understand the same in more preferred ways.

The elaborative details on the components of the engine help in understanding the core functioning. Apart from that, the core working of the V8 engine makes us aware of the complex processes inside the engine. We have also emphasized the benefits of V8 engines with their proper applications.

With the above set of information, we can quickly get a holistic idea about one of the most prominent kinds of powerful and lightweight V8 engines. This makes it quite apt for any kind of use which is among the most effective benefits of the V8 engine. Happy reading.

I am not sure where you’re getting your info, but great topic.