In this article, we will learn how to calculate air change per hour or ACPH or ACH along with formula, calculation, and table. In air conditioning or ventilation system design, the calculation of ACPH is one of the vital criteria, hence, it is essential to have a basic knowledge of it. Here, we will mainly focus on what ACPH is, it’s formula, and how do we calculate with practical project examples! Let’s explore!

What is Air Change per Hour or ACPH or ACH?

Air change per hour or air change rate is a very common term in ventilation calculation as well as ventilation design. It is abbreviated, as,

| ACPH: Air Change Per Hour | ACH: Air Change Rate |

We need to do ventilation calculations for different areas in different industries and ACPH or ACH is one of the main factors for that calculation. We will learn the detailed calculation and how ACPH or ACH is considered in it.

Air Change per Hour Basic

In ventilation design, there may be a few things,

- The room may require fresh air,

- The room may have more CO2 gas, which needs to be replaced by fresh air,

- The room may have chemical or toxic gases

- The room may have fumes, which need to be removed,

- The room may require a temperature set like my room will be limited to a maximum of 3 or 5 or 6 or 8 deg. C temperature above the atmosphere, etc.

- There may be a chance of smoke inside the room which needs to be released to the atmosphere.

These all cases are associated with the ventilation system. How do we do this ventilation system? It is simple, we add air or remove air from the area by considering air changes per hour.

Air Change per Hour Definition

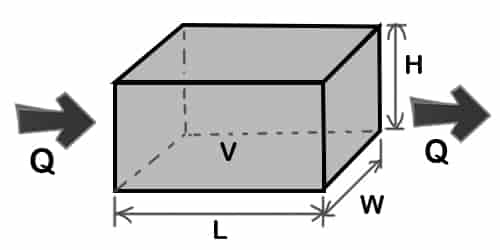

It is basically the ratio of the volume of air that is to be added or removed from an area to the volume of the area. If Q amount of air enters into the room of volume of V, then Air Changes per Hour = Air quantity / Volume = Q/V

- It is assumed that air into the area is uniform.

- Mixing of air is proper inside the area.

- Maintain uniform velocity.

- It can be stated as the number of times the air is entered into the area and exits from the area in one hour.

What Does Air Change per Hour or ACPH Mean? Meaning

Let’s try to understand the meaning of ACPH with a few examples,

What Does 1 ACPH or ACH Mean?

| 1 ACPH means, | 1-time air enters to a room and exits from the room in 1 hour, or Air fills into room 1 time in 1 hour, |

What Does 5 ACPH Mean?

| 5 ACPH means, | 5-time air enters to a room and exits from the room in 1 hour, or Air fills into the room 5 times in 1 hour, |

What is the Formula or Equation for Air Changes per Hour?

What is the Formula of Air Change per Hour in S.I. Unit?

Let us see, how do we calculate the air changes per hour? To calculate the ACPH in S.I unit, we have to do the following,

- Need to measure the supply or exhaust air quantity, by using any device, like a thermometer or velometer, or vane anemometer,

- Need to measure the room length, width & height,

- Calculate the volume of the room,

ACPH will be air quantity divided by room volume, That means,

Where,

- Q = Air quantity, in m3/hr (Cubic meter per hour or CMH)

- L = Length of room, in m

- W = Width of the room, in m

- H = Height of the room, in m

- V = Volume = L x W x H, in m3

Note, ACPH is defined in various standards and it is fixed for specific areas or specific applications. Suppose, if it is a battery room, the ACPH value is 6, and in a cable cellar, the APH value is 4. These values are predetermined and available in various standards like ASHRAE.

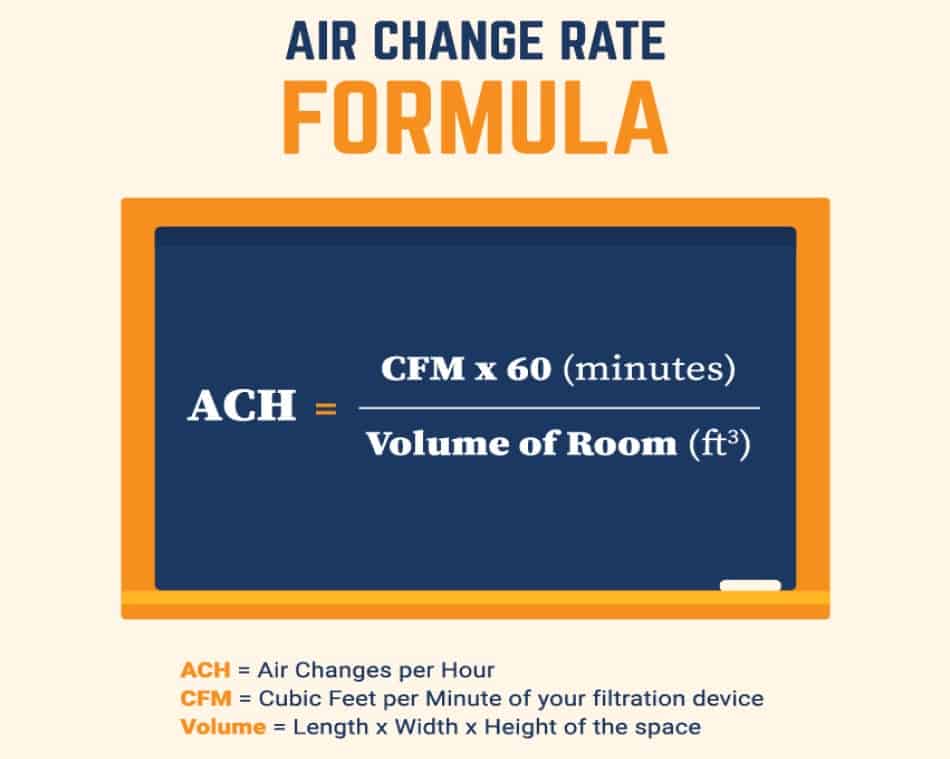

How Do You Calculate Air Change per Hour with Formula in F.P.S unit?

After deriving air changes per hour, let’s see how to calculate air changes per hour in F.P.S. To calculate the ACPH, we have to know the following,

- Need to get the air quantity

- Need to get the room size (length, width & height)

- Calculate the volume,

ACPH will be air quantity divided by room volume, Mow, consider,

- Q’ = Air quantity, in ft3/min (Cubic Feet per Minute or CFM)

- Q = Air quantity, in ft3/hr = 60 Q’

- L = Length of room, in ft

- W = Width of the room, in ft

- H = Height of the room, in ft

- V = Volume = L x W x H, in ft3

ACPH will be air quantity divided by room volume, That means,

Air Change Rate with Different Units

Air change rate is expressed in the below equation,

Q = V x ACPH

or ACPH = Q / V [When Q & V are in S.I Unit]

or, ACPH = Q x 60 / V [When Q & V are in F.P.S Unit]

Where,

- ACPH = air changes per hour

- Q = Air flow rate and units are mentioned below.

- V = volume of the space or room and units are mentioned below.

| SI Units | F.P.S Units |

| Q = Air quantity in m3/hr | Q = Air quantity in C.F.M (Cubic Feet per Minute) |

| V = volume of the in m3 | V = volume of the in ft3 |

ACPH Explanation

If 7200 m3/hr (Q) air is supplied to 120m3 (V) volume room,

- ACPH will be = Q / V

- ACPH = 7200/120

- ACPH = 6. So, the value of ACPH is 6.

If 800 CFM (Q) air is supplied to 4800 ft3 (V) volume room,

- ACPH will be = Q x 60 / V [For simple understanding, 1 CFM = 1 x 60 ft3 /hr]

- ACPH = 800 x 60/4800

- ACPH = 10, Hence, the value of ACPH is 10.

Standard Air Change per Hour or ACPH Table or Chart

ACH or ACPH is based on industry, national standards, international standards, client-specific requirements as well as location. However, based on our experience, a reference list is given,

| Name of Room/Areas | ACPH or ACH |

|---|---|

| General Areas | 0.5 – 1.0 |

| Corridors | 0.5 – 1.0 |

| Meeting rooms | 4 – 6 |

| Normal Stores | 6 – 10 |

| Chemical Stores | 10 – 15 |

| Educational Facilities | 4 – 6 |

| Gymnasium | 4 – 6 |

| Student Classrooms | 6 – 12 |

| Laboratory | 4 – 6 |

| Library | 4 – 10 |

| Office Buildings | 0.5-1.0 |

| Office Rooms | 0.5-1.0 |

| Municipality Buildings | 0.5-1.0 |

| Public Assembly Spaces | 0.5-1.0 |

| Halls for public gathering | 4 – 6 |

| Auditorium | 4 – 12 |

| Electrical Room | 0.5 |

| Pump Room | 6 -12 |

| DG Room | 6 – 12 |

| Fuel Oil Tank Room | 10 – 12 |

| Pantry | 6 – 8 |

| Kitchen | 10 – 15 |

| Toilet | 6 – 10 |

| Bathroom | 6 – 10 |

| Battery Room (Lead-acid) | 12 -15 |

| Battery Room (Ni-Cd) | 5 – 6 |

| Engine Hall | 4 – 6 |

| Locomotives Room | 5 – 12 |

| Laboratory Room | 6 – 12 |

| Residence | 0.5 – 1.0 |

| Interview rooms | 6 |

| Secondary enclosures (animal holding rooms) | 10 – 15 |

| Contaminant Laboratories | 6 – 15 |

| Clinics | 8 – 12 |

| Protective Isolation Units | 15 -16 |

| Infectious Disease and Virus Laboratories | 6 |

| Pools with no spectator areas | 4 – 6 |

| Spectator areas | 6 – 8 |

| Therapeutic pools | 4 – 6 |

| Engine Room | 20 – 30 |

| Gas-Phase Filtration | 6 |

| Dye House | 15 – 20 |

| Compressor Hall | 15 – 20 |

| Boiler Room | 20 – 30 |

| Heat Treating Room | 60 – 100 |

| Steel Furnace Building | 40 – 50 |

| Steam Turbine Room/Hall | 12 – 15 |

| Gas Turbine Room/Hall | 12 – 15 |

| Gas Turbine Enclosure | 50 – 70 |

| Transformer Room | 15 – 20 |

| Tear Gas and Pepper Spray Storage | 12 |

| Paper machine buildings | 10 – 25 |

| Burner Area (Close to 4 to 6 m around the steam generator) | 60 |

| Conveyor Areas | 2 – 5 |

| Underground Tunnels and Conveyors | 2 – 5 |

Air Changes per Hour ACH for Specific Companies/Applications

There are some different ACPH requirements for different companies or applications and the same is listed as below:

For Offshore Platform Applications

| Name of Room | Air Changes per Hour |

| Sewage Tank/Pump Room, Drain Tank/Pump Room, Material Handling Rooms, Workshops (Mechanical/Electrical), Reach Truck Storage for Converter Rooms, Battery Rooms, Emergency Stairs, Deck Stores etc. | 6.0 |

| AC/DC Room, Converter Room | 0.5 |

| DC Pull in Room | 0.5 |

| Toilets | 10.0 |

| Hazardous Store | 12.0 |

| Paint Store | 12.0 |

| Heli -Center, Primary Muster Area, ERT Room, First Aid Room, Control Room, Communication Room, Air locks, Elevator, Tunnel etc. | 1.0 |

| Chiller Room | 4.0 |

| Flushing mode | 0.5 – 1.0 |

| General Areas | 0.5 |

For ADNOC Project Applications (Onshore)

| Name of Areas | ACH |

| Switchgear Room | 1 |

| Air Lock | 1 |

| HVAC Room | 1 |

| Battery Room | 6 |

| Telecom Room | 1 |

| Starter Panel Room | 1 |

| Instrument Rack Room | 1 |

| Operator’s Room | 1 |

| Cable Cellar | 6 |

| Workshop | 1 |

For ADNOC Project Applications (Offshore)

| Name of Areas | ACPH |

| Battery Room | 12 |

| Warehouse, store | 2 |

| Laboratory | 6 |

| Toilet / shower room | 12 |

| Workshop | 2 |

| Janitor | 1 |

| Accommodation Rooms | 0.5 |

| Exercise room | 10 |

| Gym & Indoor sport room | 10 |

| Washing and Dressing room/ Locker room | 12 |

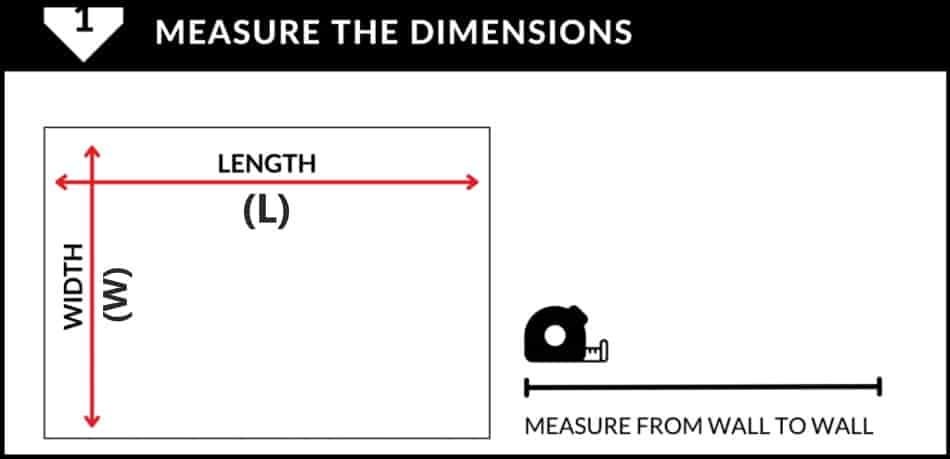

How to Calculate Air Changes per Hour? Steps

We have already learned the formulae of calculating air changes per hour, here, look at all the simple steps for the calculation in S.I units

Step #1 Measure Air Quantity

If the air quantity of a particular room is known the same data can be used to calculate ACPH. If it is not available, it is required to measure the air quantity. Say, Measured Air Quantity is, Q in m3/hr

Step #2 Measure Room Length

If the room length of a particular room is known the same data can be used to calculate air change rate. If it is not available, it is required to measure the length of the room. Say, Measured Room Length is, L in m

Step #3 Measure Room Width

If the room width of a particular room is known the same data can be used to calculate air changes per hour. If it is not available, it is required to measure the width of the room. Say, Measured Room Width is, W in m

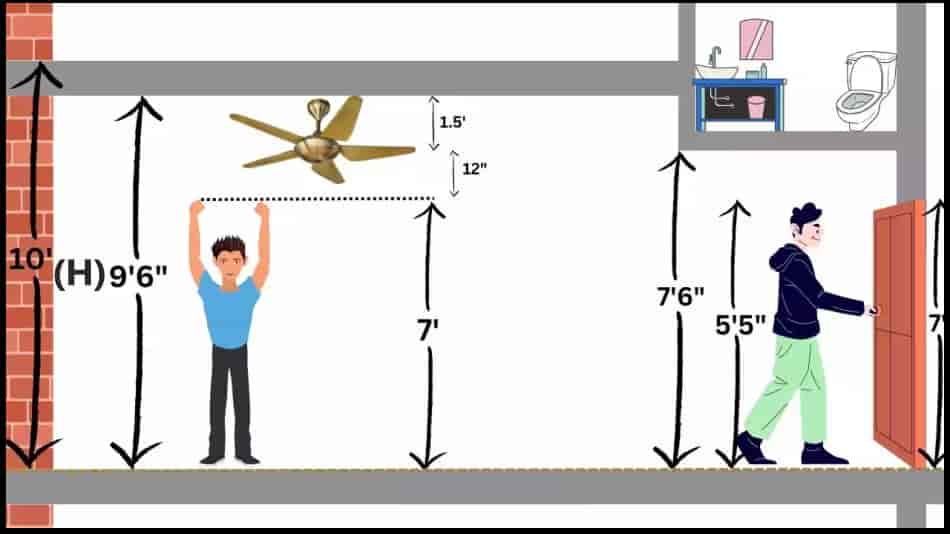

Step #4 Measure Room Height

If the room height of a particular room is known the same data can be used to calculate air changes per hour. If it is not available, it is required to measure the height of the room. Say, Measured Room Height is, H in m

Step #5 Volume Calculation

Now, in this step, room volume needs to be calculated. We have got the value of room length, width & height.

- Calculate the volume,

- V = length x width x height = L x W x H in m3/hr

Step #6 ACPH Calculation

We know air quantity (Q) and room volume V. So, from the definition of air changes per hour or ACPH, we can write:

- Air changes per hour (ACH or ACPH) = Q / V = Q / (L x W x H)

Example of ACPH or Air Change per Hour Calculation

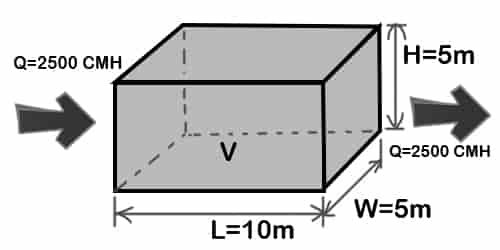

Let’s take a simple example. You are in a room and the room needs to be ventilated. The size of the room is 10m x 5m x 5m.

Measure air quantity = 2500 CMH, So, what is the air changes per hour?

Calculation

- Air quantity, Q = 2500 CMH

- Length, L = 10m

- Width, W = 5m

- Height, H = 5m

Hence, Volume V = 10 x 5 x 5 m3

V = 250 m3

As per formula,

ACPH = Q / V = 2500 / (10 x 5 x 5) = 10

Hence, with the simple mathematical calculation, the value of ACPH becomes 10.

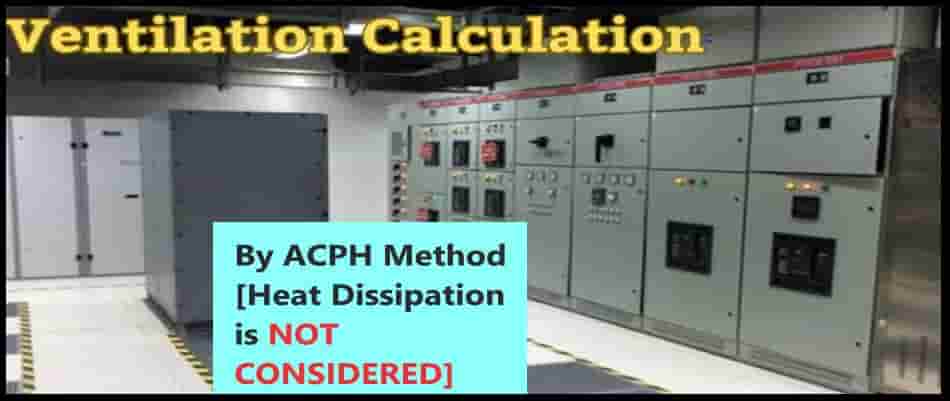

Is the ACPH only Method for Ventilation Calculation? Understand with Electrical Room

In the case of ventilation calculation, ACPH is not the only method by which the calculation or the equipment selection is done. For example, let us consider, an electrical room which has heat-generating equipment. To understand, first we will calculation air quantity based on ACPH,

- Electrical room length = 10m

- Electrical room width = 6m

- Electrical room height = 5m

- Equipment heat generation = 12.0 kW

So, volume = 10 x 6 x 5 = 300 m3

We know from the standard ACPH list,

- ACPH for electrical room = 6

- Or, Air quantity, Q1 =ACPH x 300 = 6 x 300 = 1800 m3/hr

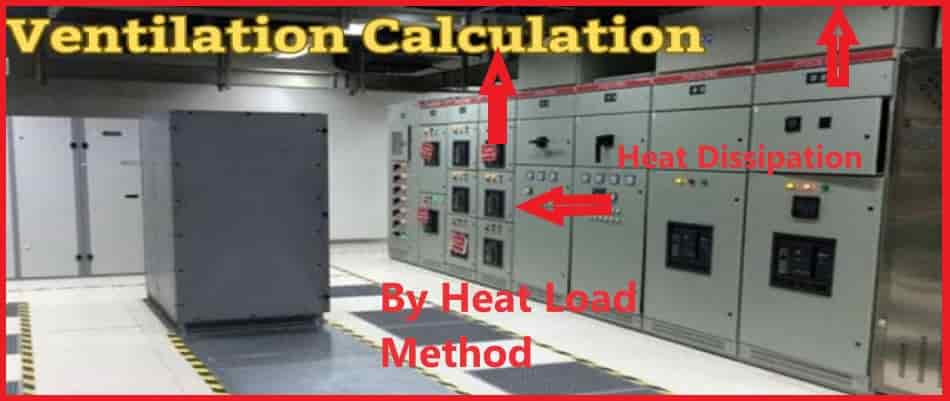

Now, if 1800 m3/hr is provided in the electrical room, the room will be ventilated, but what about the equipment heat, generated by electrical items? Will it be restricted to be heated? No, unless, a separate calculation method is to be adopted. This second method is called the heat load method. A standard formula for this method,

Heat, q

- q = m x Cp x Δt

- q = ρ x Q x Cp x Δt

- Q = q / (ρ x Cp x Δt)

Where,

- q = Heat Generated in kW = 12.0 kW

- Cp = Specific Heat = 1.005 kJ/kg-K or kJ/kg-Deg. C (Same)

- ρ = Density of air = 1.2 kg/m3

- ∆T = temperature difference between outside temperature and inside temperature= 5ºC [∆T depends on the project requirements, here it is 5ºC]

As per the equation,

- Q2= q / (Cp x ρ x ∆T) in m3/s

- or, Q2 = 12.0 / (1.005 x 1.2 x 5) in m3/s

- or, Q2 = 1.99 m3/s = 7177 m3/s = that is > Q1

Hence, Q2 is more than Q1.

Air quantity in the ACPH method is less than the heat load method, in this example. Hence, during ventilation calculation, both methods are to be considered, as in many cases, it varies, and we have to select whichever is higher.

ACPH or ACH Project Example for Pump Room

Let us take a project example,

Input Data

From the drawing, the following data, are as follows,

- Length of pump house, L = 60m

- Width of pump house, W = 12m

- Height of pump house, H = 10m

- ACPH = 10

- Heat Load data, q = 14.4 kW

- Temperature difference = 5ºC

Design Calculation

ACPH Method

Volume of pump house, V = L x W x H = 60 x 12 x 10 m3

Air quantity, Q = V x ACPH = 60 x 12 x 10 x 10 = 7200 m3/hr

Heat Load Method

Q2 = q / (Cp x ρ x ∆T)

or, Q2 = 14.4 /(1.005 x 1.2 x 5) m3/s

or, Q2 = 2.39 m3/s = 8604 m3/hr

Hence, 8604 m3/hr air quantity is selected.

Equipment Selection

The pump house needs to be positively ventilated, which means supply and exhaust to be provided and supply shall be more than exhaust.

As per drawing, 3 nos. of supply fans, each of 2868 m3/hr (8604/3) nos.

Exhaust fans, 3 nos. 2868 x 0.8 = 2295 m3/hr.

The numbers and capacity of supply fans and exhaust fans shall be based on the building layout, and space availability.

Why ACPH is an Important Factor?

ACPH is very important to design a ventilation system, and proper ACPH selection incurs a proper ventilation design. A proper ventilation system helps, as follows,

- It removes pollutants from the ventilated space.

- It supplies fresh air,

- Improves indoor air quality

(IAQ)

(IAQ) - It helps to maintain inside temperature, and humidity up to a certain level.

- It can help pressurize the space by supplying more air and exhausting less air.

- It gives a certain level of comfort to human beings.

- It restricts to increase the temperature up to a certain level which helps all equipment to maintain it’s limited temperature.

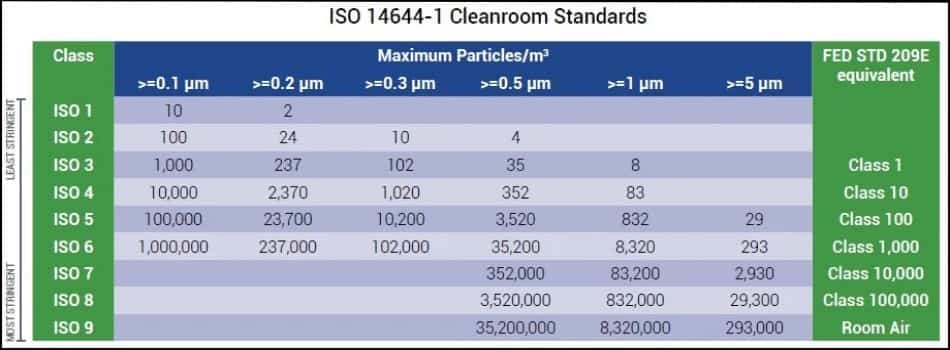

Air Change Per Hour for Pharma Industries/Clean Room

When the air in the room is replaced every 10 minutes or less, the air change per hour (ACPH) becomes 6, which is better. Although ACPH is not standardized, it has been documented that a higher ACH reduces the risk that disease will spread. Air Change per hour formula for Clean Room as follows:

ACPH = 60Q / Volume [in FPS unit]

Pharmaceutical clean rooms maintain HVAC clean room quality by changing the air. An hour’s worth of air changes can be measured by the number of times the air in any room is changed.

An HVAC system will deliver the same amount of air in one hour if the volume of the room and the volume of its delivery equal each other. With 60 air changes per hour, roams will have 60 times more air supply than the volume of the room. Air changes should be made at least 20 times per hour, and roars should be cleaner.

| Class of Clean Room | Air Change Per Hour Requirement |

| 100 | 240-480 |

| 1000 | 150-240 |

| 10000 | 60-90 |

| 100000 | 5-48 |

It depends on the type of room, the number of personnel in the area, and how frequently the room is accessed on the number of air changes per hour required. A better clean room class requires more air changes per hour than a lower class

It is necessary to change the air more frequently in areas where dust is generated, such as those used for granulation and tablet compression. The dust must be removed quickly in these areas, so air changes per hour are more frequent.

Air Changes Per Hour (ACPH) in Battery Room

Depending on the configuration of the battery room, the ventilation approach may be more suitable. A battery system could be installed in a dedicated enclosure, in a shared office space, or in a warehouse that is much larger than the battery room.

Dedicated Enclosure

The continuous ventilation at 1 CFM per square foot is a practical and simple solution for battery rooms with a dedicated enclosure that are not air conditioned. It is possible to mount the exhaust fan on the ceiling or on the wall.

For wall mounted exhaust fans, there must be enough clearance between the fan and ceiling for service and maintenance. A fan used for exhaust must discharge to the outdoors in accordance with Uniform Mechanical Code (UMC) & International Mechanical Code (IMC). Air flow can be monitored by installing a flow switch upstream or downstream of the fan.

Space Sharing

A localized ventilation system is ideal for battery systems installed in large spaces that are not air conditioned, such as warehouses. H2 gas can be removed from the building by installing the batteries under a hood with an exhaust system. Due to the fact that the ventilation rate calculation is based on the space under the hood, 1 CFM per sq ft is appropriate for this configuration.

As a result of this design, the ventilation system is relatively small and serves two purposes: removing heat generated by the batteries and removing H2 gas. This type of application can be handled with packaged hoods and exhaust systems. In order to meet UMC and IMC construction requirements, the hood design must meet these requirements. Accordingly, a flow switch should be installed upstream or downstream of the exhaust fan to comply with ventilation monitoring requirements.

Formula of Air Change per Hour in Battery Room

When using an HVAC system, air changes per hour refer to the amount of air that is supplied and removed from a space in one hour. It is calculated by dividing the volume of air per hour by the volume of the room or area. It is as the name suggests that air changes are replacements of old air with new air every hour. Clean rooms and battery rooms have different air changes per hour.

Battery room ventilation is calculated using EN specific standards for standby DC power systems and AC UPS systems. The following formula can be used to calculate the ventilation flow rate in a battery room.

Q = v* q*s*n * I-gas* Cn/100

- Q = Air flow of Ventilation

- v = Necessary Hydrogen Dilution Factor

- q = Release rate of Hydrogen

- s = Safety Factor

- n = Cell Numbers

- I-gas= Current Gas Production While Charging

- Cn = Battery Capacity Rate

According to the IEC, ventilation airflow is calculated by the following formula for battery locations or compartments:

Final Formula

Q = 0.055 * n * I-gas * Cn /100 m3/h

Natural Ventilation

Air inlets and outlets are required in battery rooms, with a minimum free area of opening calculated as:

Area = 28 * Q cm2.

It is assumed that the air velocity is greater than 0.1 m/s for this calculation. There should be at least 2.5 times Q m3 of free volume within large and well-ventilated rooms. In this calculation, air velocity is taken to be greater than 0.01 meters per second.

The inlet and outlet must be located at the best possible location to create the best conditions for air exchange. Openings on opposite walls should be separated by a minimum of 2 meters when openings are on the same wall. Exhausting the charging area or room’s air into air is recommended.

Pre-charging requires the removal of removable covers or seats. Battery containers, compartments, or covers must have adequate ventilation openings to prevent dangerous gas accumulations.

Forced Ventilation

Forced ventilation should be used if natural ventilation cannot achieve airflow Q to provide the required exchange of air for the mode of operation.

Air Changes per Hour for Battery Room

Presently in all industries, Ni-Cd. VRLA etc. types efficient batteries are used which generates a very less amount of H2 gas. In the earlier time, lead acetate type batteries are used which generates a large amount of H2 gas. As H2 gas is dangerous and it has a tendency to explode after a certain percentage of accumulation in case of getting any spark, it is required to remove from the battery room. Standard practice for battery room ACPH shall be as follows:

- ACPH for battery room consist of Lead acetate = 12 to 20

- ACPH for battery room consist of Ni-Cd = 6

- ACPH for battery room consist of VRLA = 6

- ACPH for battery room (as per ASHRAE) = 5 [for Efficient batteries]

Importance of Air Changes per Hour (ACPH)

- A suitable ventilation system should be in place.

- Getting rid of dust, smoke, and fumes from a space, a room, or a building.

- Gases such as carbon dioxide must be removed from the area.

- In order to maintain a clean room, undesirable particles must be removed.

- Keeping a clean room requires removing viable particles from non-viable particles

Standards for ACPH

Refer to ASHRAE 62.2-2016, “Ventilation and Acceptable Indoor Air Quality in Residential Buildings” for ventilation details.

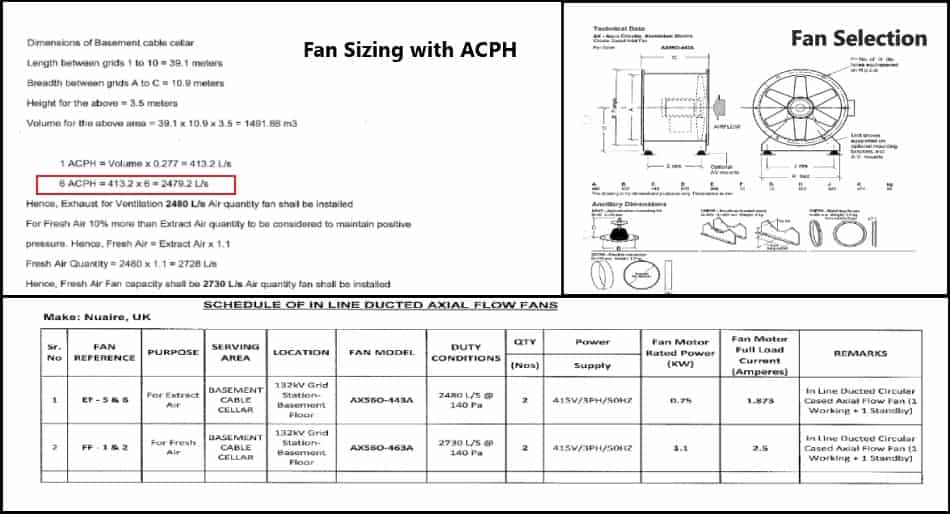

Practical Project Example Like on Job Training

To be updated shortly with below:

- Project Details

- Project Drawings (3D Models)

- Equipment Loads

- Design Calculations

- Equipment Selection

- Updated 3D Models

- Actual Site Execution

FAQs for Air Change per Hours

What is 10 air changes hourly?

10 ACPH means, 10-time air enters to a room and exits from the room in 1 hour, or

Air fills into the room 10 times in 1 hour,

How often does air change in a room?

Air changes per hour in a room depends on the applications. If its a case in our room where we stay, it can be 0.5 to 1 or sometimes, 2.

If it is a battery room, then it has to be increased and normally it is considered as 6-12 depends on the type of battery.

How many air changes per hour should a bathroom have?

For Bathrooms, air changes per hour is considered around 6.

How do you calculate air changes in a room per hour?

To calculate Air Changes Per Hour (ACPH), first it is required to measure the air quantity and room volume.

Then simply make ratio of air quantity and room volume.

ACPH = Q / V [When Q & V are in S.I Unit]

ACPH = Q x 60 / V [When Q & V are in F.P.S Unit]

What is a good air charge per hour?

According to the American Society of Heating, Refrigerating and Air Conditioning

Engineers, homes should have 0.35 air changes per hour but not less than 15 cubic feet

of air per minute CFM in ventilation and acceptable indoor air quality.

What is the formula for calculating CFM with air changes per hour?

A room’s volume is divided by the cubic foot capacity of the HVAC unit in order to come up with the formula that determines how many cubic feet of air can be provided per hour. Whenever we do an analysis of the volume of air per minute, we always get CFM, and that is what we always get.

What does one air charge per hour mean?

The number of times that the air in a room is replaced with completely new air in an hour is called air changes per hour. An air change rate of ‘7’ means that a room’s entire volume of air is replaced seven times each hour.

How do you calculate CFM of air charges?

ACH = CFM * 60 / (Area * Height)

CFM stands for cubic feet per minute, but that is the volume of air per minute. It is necessary to translate air changes per hour into hours before you can calculate air changes per hour. As a result, the equation above is multiplied by 60. A room’s volume is calculated by multiplying its length by its width by its height.

How much fresh air does a person need?

Living area air changes should not be less than 15 CFM or 7 liters per second per person along with additional 3 CFM per 100 square feet as per ASHRAE 62.2

For a building designed for 200 people and a floor area of 5,000 square feet, the required ventilation rate should be as follows:

Nos of people = 200

Fresh air for 200 people [@ 15 CFM per person] = 200×15 = 3000 CFM

Fresh air for 5000 square feet [@ 3 CFM per 100 square feet[ = 150 CFM

Total Fresh air requirement = 3000 + 150 = 3150 CFM

Fresh air rate = Total fresh air / area = 3150 / 5000 = 0.63 CFM per square foot.

What is the air charge per hour in HVAC?

Air changes per hour refer to the amount of air supplied and removed from an area at the end of an hour by a HVAC system. Volume of air per hour divided by the volume of the room or area is ACPH. By definition, air changes mean that the old air is replaced with fresh air within an hour.

What is the CFM Formula?

CFM = fpm * Area [fpm = feet per minute

Where, a foot per minute is represented by fpm. Substituting the area after the area is squared with the FPM value will yield cubic feet per minute.

CFM = CMH * 1.7 if we want to convert from CFM to CMH.

How many CFM do I need for a 12 by 12 room?

An average room or building requires one cubic foot of air per square foot of floor area.

Are 2 air changes per hour good?

An air change per hour will occur if the HVAC system supplies the same amount of air in one hour as the volume of the room. An air supply of 60 changes per hour will be 60 times greater than the volume of a room with 60 air changes per hour. A clean room should maintain at least 20 air changes per hour.

What is a good ACH?

Home energy efficiency scores should be below 1 ACH, and ultra-efficient homes should be in the range of 0.2 to 0.6 ACH. To find out what your builder’s typical ACH score is if you’re planning on buying a home and are looking for an airtight one, ask your builder.

Conclusion

So, finally, we have got the basic idea about air changes per hour or ACH or ACPH along with various examples, and diagrams. If you have any doubts, please contact us. Thank you for reading.