What is a progressive cavity pump? Any idea! In this article, we will learn all about the basic details of the progressive cavity pump, its definition, parts, working principle, advantages, disadvantages, and applications. Let’s explore!

What is a Progressive Cavity Pump?

Progressive Cavity Pump Basics

Let’s start with the basics of a progressive cavity pump. When we need to steal or pump fuel in transporting media, the one device which comes to our mind is the pump. There are various types of pumps with different applications, and these pumps are used in various conditions. Today in this blog, we are going to study one type of pump which is enriched with an excellent application.

Today we will learn about a progressive cavity pump or a positive displacement pump (positive displacement in direction). It offers us positive displacement and is distinctively delineated for abrasion resistance in difficult pumping situations.

What is the Progressive Cavity Pump?

The progressive cavity pump is an exceedingly convertible pump and can be used in numerous pumping applications.

A progressive cavity pump can be defined as a positive displacement pump which works based on the progress of the rotor. It is often called as,

- PC pumps

- Eccentric screw pump

- Progg cavity pump

- Cavity pump, etc.

This progressive pump is specially used when we need positive displacement.

- The most commonly used or known pump is the centrifugal pump, but this pump is totally different in applications from the centrifugal pump. The centrifugal pump is used where we need to pump water with low viscosity and having constant discharge pressure.

- The Progressive cavity pump is also known as a positive displacement pump due to its movement in a positive direction, and it is also a bi-directional pump as it moves in either direction.

- Its stator and rotor assembly allows generating interim passages or chambers to draw fluid into the progressive cavity pump, and “progress” through the assembly deriving in the fluid is dismissed through the discharge hole.

- Also, it is a sort of economical choice while we are looking for these applications, but when one of these applications changes, we cannot go with a centrifugal pump. In this situation, we have a great and perfect choice which is the progressive cavity pump as it offers us a wide range of applications.

- A well-applied progressive cavity pump will offer us years of authentic service in pumping operation.

When to use Progressive Cavity Pump?

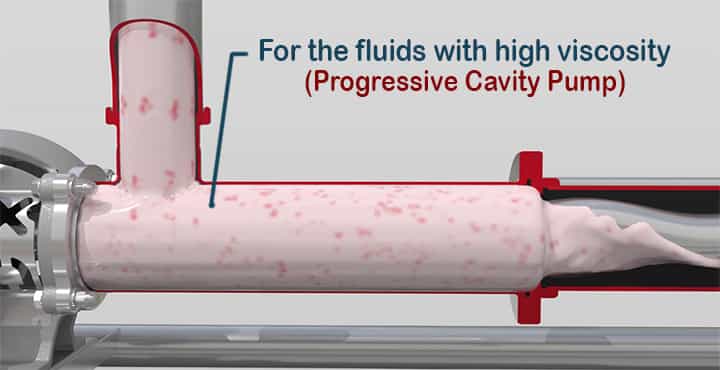

For the fluids with high viscosity

When pumping operations need to operate on high viscous fluid, we need to use a progressive cavity pump, and thus these operations are not matched for the centrifugal pump.

- In simpler words, when a fluid has a viscosity (thickness) higher than that of the water, we can use a progressive cavity pump. While operating on such fluids, Centrifugal pumps flatter technically and become very inefficient, and thus the flow of fluid goes down and at some point, it stops and combines, resulting in power consumption, it goes up.

- Economically, it’s not well-suited. On the other hand, while operating on viscous fluid, the progressive cavity pump becomes very efficient mechanically, and thus it lowers the power consumption and flow goes up.

- A progressive cavity pump is thus an ideal option for high viscous fluids. In insertion, a progressive cavity pump will always have continuity inflow, whatever will be the viscosity of the fluid, and it does not matter.

- In the case of variable fluid viscosity, a progressive cavity pump is the best option since it provides constant flow, regardless of the viscosity of the fluid.

When varying flow is required

The Progressive cavity pumps come in handy when we require an application of varied flow. In a progressive cavity pump, it is quite easy to regulate the flow of the liquid according to our application.

- The control of flow is achieved just by regulating the speed of the pump.

- It is used in boilers where we need fluid for feeding applications, where varying flow is desirable.

In separating fluid devices

The progressive cavity pump is the best option when we need to separate the fluid. Let’s understand this point with an example. Let’s assume we want to pump oil and water in the separating device. The separation process will become much easier when oil droplets are larger in size than water droplets.

- In general, pumps, what happens is that while separating the fluid, these pumps blend the oil and, hence, oil droplets become very small, and hence it impacts the separation process.

- On the other hand, operating on the progressive cavity pump this process becomes easier since the progressive pump does not try to blend or emulsify

the oil droplets.

the oil droplets.

Suctioning Conditions

When suction conditions of the pumping operation are not ideals, means for drawing the fluid into the assembly, we need different pressure and torque conditions even in the same operations, the progressive cavity pumps are known to be the best option among the other pumps.

- Progressive cavity pumps need very low drawing torque as compared to any other pump as it possesses low internal pump velocity.

- Progressive cavity pumps can also fill even if the suction pressure is very low.

- On the other hand, centrifugal pumps cannot work in low-pressure conditions.

For Dosing & Metering

This type of pump has low pulsation, hence, it can be easily used for dosing and metering applications.

When fluids have abrasive particles

The best application of the progressive cavity pump is when the fluid contains abrasive particles. Other types of pumps do not perform well when they have particles because of their metal body construction, and thus it does hold very well because of low tolerance.

- A normal pump will wear out when there are abrasives present in them.

- The same would happen with centrifugal pumps as they will also clog due to metal particles.

- The key for the smooth operation of a progressive cavity pump is the design motor or stator which ensures a lower internal velocity of liquid than that of the other pumps.

When Require a Precision Flow

We already know that a progressive cavity pump provides precise flow in each revolution in case a variable flow drive is used.

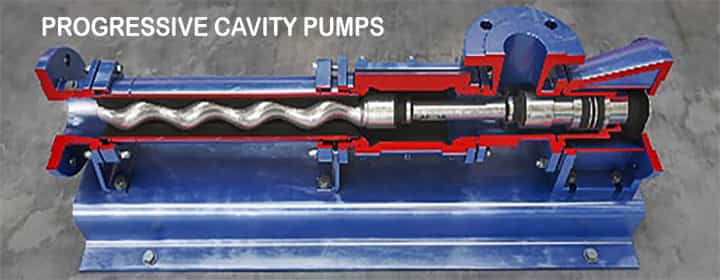

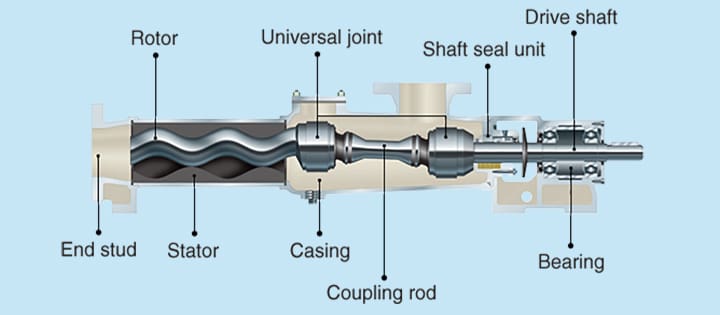

Parts of Progressive Cavity Pump

Let’s see what are the basic parts of a progressive cavity pump? The parts of this kind of pump shall be, as follows

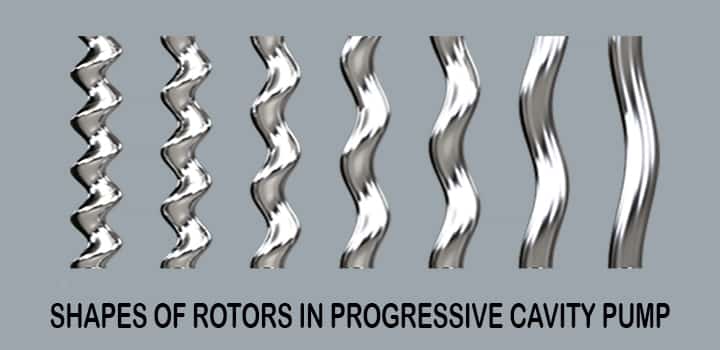

Rotor

- The typical design of the progressive cavity pump consists of a stator and rotor. The Design of the rotor comprises of or is made up of the shape of helix design.

- This rotor is typically made up of steel, which is covered with a smooth surface named chromium metal. This rotor is fixed inside a stator made up of an elastomer.

Stator

- The rotor is fixed inside a stator by linked arms and thus it allows them to roll inside the stator.

- This motion is possible because of the bearing which holds the rotor inside the stator.

Joints

In this type of pump, axial force, as well as torque, is created between the rotor and main drive.

Joint helps to support these forces.

Pump Body Parts & Flanges

- Pump body part means the part where the liquid is pumped in.

- In this part, the pump suction flange is mounted and the liquid is entered into the pump through this suction flange.

- On the discharge side, a discharge flange is mounted to discharge the liquid from the pump.

Other Parts

Apart from the above parts, there are many other parts in the progressive cavity pump. These are as follows,

- Packing & sealing

- Coupling

- Connecting rod

- Driver like motor

- Bearing

- Inspection ports, etc.

How Does Progressive Cavity Pump Work?

Let’s see the working principle of Progressive Cavity Pumps! As progressive cavity pumps consist of the two main important parts such as stator and rotor, as the rotor moves inside the stator, there are cavities left. Cavities are a place where fluids reside.

Step#1 Working Start from the Shape of Rotor

The function of the cavities is to maintain the shape of the rotor and when the rotor turns, and thus it pumps the fluid inside it. For smooth operation, it is important to manufacture the whole construction with high precision.

- This corkscrew look-alike construction is highly affected by the fact that which type of material is being transferred through it.

- Because of its intricate yet very precise design, it does have a very tight tolerance between the stator and the rotor body.

Step#2 Pump draws liquid or slurries

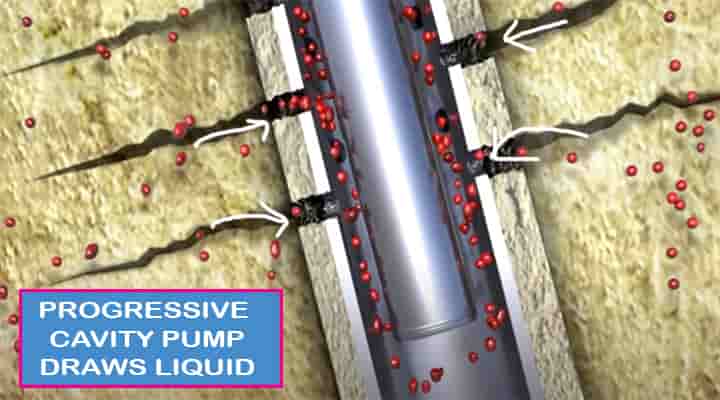

The progressive cavity pumps draw liquid or slurries inside the assembly through a suction inlet which then caters to the casing. Inside the casing, there is a construction assembly of a helical-shaped rotor and stator. In the below image, how progressive pump draws liquid shows undergroud.

In over ground installation, liquid or slurries are simply drawn to the pump through the suctin nozzle.

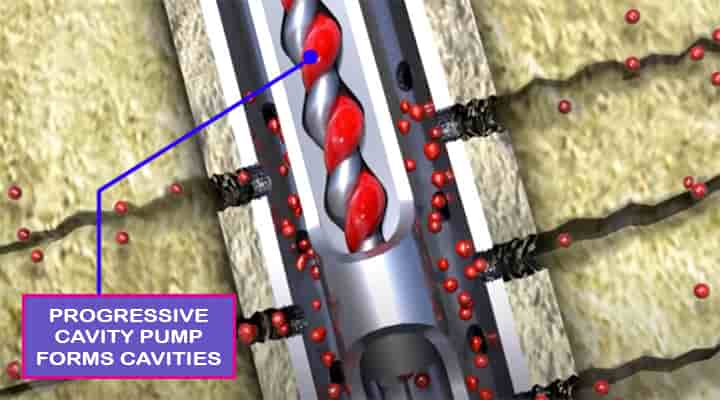

Step#4 Cavities formed

- The stator is sort of offset to the rotor assembly.

- And thus, when the rotor starts to rotate and after a point, it comes in contact with the stator, small cavities or holes start to form. This fluid goes through or “progressive” through these cavities or holes.

- In the below image, after liquid ingressed into the pump, how the cavities are fromed, is shown.

Step#4 Discharge

This operation continues till fluid is discharged out of the casing through a discharge port. The heat generated by stator and stator assembly can result in the failure of the pump, thus we cannot allow the progressive pump to run dry.

In general, the presence of abrasive particles will wear out the life of the pumps, but since the construction of the progressive cavity, the pump is made in a way that does not shorten the life of the pump. It offers reliable life even with the use of viscous fluid.

Due to its different shape, the fluid which passes through it contains metal particles that act as a lubricant and help strengthen the life of the pump.

What is the difference between a Centrifugal and Positive Displacement Pump?

We have already learned the basics of progressive cavity pumps and how it operates. This pump is basically a positive displacement type pump. Now let’s try to find out when to use the progressive pumps?

Although centrifugal pumps are widely used in several industries for its reliability, easy availability, reasonable cost, there are few reasons to select progressive cavity pumps over centrifugal pumps for a few applications. A difference between these two pumps is captured to illustrate the above.

| Description | Progressive Cavity Pumps | Centrifugal Pumps |

| Viscosity | Suitable for high viscous fluids. In case, viscosity is increased, the flow rate will also be increased. | Not suitable for high viscous fluids. In case, viscosity is increased. The flow rate will be reduced due to losses. |

| Working | It traps some amount of fluid and forces it to discharge and increases the pressure. | The liquid comes into contact with the impeller and due to its centrifugal force, as well as velocity head reduction, pressure is increased. |

| Pressure | Flow rate same with the change in pressure. | The flow rate is different with a change in pressure. |

| Efficiency | Efficiency is slightly varied with variations in pressure. | Efficiency is maximum at a specific pressure. Apart from that point, any variation in pressure, efficiency is decreased. |

| Suction capacity | Suction capacity is very high and it is about 9 mWC on average, as it creates a vacuum. | These types of pumps cannot create a vacuum. |

| Bi-directional flow | The flow can be a bi-directional pump in that a suction port can act as a discharge and at the same time, a discharge port can act as a suction port. | Here, it is not possible. |

| Abrasive particles | It is suitable for abrasive particles. | It is not suitable for abrasive particles. |

Difference between Progressive Cavity Pump vs Screw Pump

Let’s see the difference between progressive cavity pump and screw pump, as follows:

| Progressive cavity Pump | Screw Pump |

| Suitable for high viscous fluids. | Suitable for clean fluids. |

| Suction capacity up to 9 mWC | Suction capacity up to 7.5 mWC |

| Normally used up to 50bar | Normally used up to 120 bar |

| Suitable for abrasive materials | Not suitable |

Difference between Progressive Cavity Pump vs Gear Pump

Let’s see the difference between progressive cavity pump and gear pump, as follows:

| Progressive cavity Pump | Gear |

| Suitable for high viscous fluids. | Suitable for clean fluids. |

| Suction capacity up to 9 mWC | Suction capacity up to 7.5 mWC |

| Normally used up to 50bar | Normally used up to 15 bar |

| Suitable for abrasive materials | Not suitable |

Advantages of the Progressive Cavity Pumps

The ease in operation, as well as the well-mannered and clean process, is a notable property of the whole assembly. While looking at the whole operation process, let’s look at the Advantages of the Progressive Cavity Pump.

- Best for solid and hard fluids and can also grasp multiphase and fluids with abrasive particles in them. It allows users to depend upon or choose fluids from numerous options since there is no limitation of smooth liquid with any abrasive.

- Good for fluids with high viscosity since it ensures steady and smooth flow for every kind of fluid. For starting the whole operation, complete assembly requires a low-net suction net as its impressive design ensures low power consumption.

- For any other general pump, the progressive cavity pump offers high accuracy in operation, and it also ensures no vapor lock of the heating liquid. These pumps are available in a bi-direction option, and hence they can be handled in either direction.

- The main advantage of having a bi-directional pump is that a suction port can act as a discharge and at the same time, a discharge port can act as a suction port. While using the Progressive Discharge Pumps, we can perform the whole operation vertically, and I think it is the real beauty of its amazing and unique design.

- The whole conducted operation of the progressive cavity pump is quiet in manner and hence makes it much more desirable.

- Suction capacity is very high and it is about 9 mWC on average.

- Low pulsation.

- Smooth operation and long life.

- Low operational cost

- It can be vertical or horizontal based on the requirements.

- High operating range, approx -20◦C to +200◦C

- Nos. of stages are varying and depends on the project requirements.

Disadvantages of the Progressive Cavity Pumps

With some notable and impressive advantages, there are some disadvantages which are as follows:

- As we studied earlier, the stator and motor assembly have a tight fit between them, and that’s why it needs to lubricate the sliding surface. And thus, running the pump dry can be the main reason for the pump failure. (The progressive cavity pumps are considered self-priming, but the sliding contact between assemblies can be problematic in instances, and hence it requires regular lubrication).

- The cost of installation for these pumps is high since low-speed drives also come with a pair of variable frequency drives popularly known as VFD.

- The low speed of the progressive cavity pumps also resulted in low and reduced flow, and it is proved as a disadvantage in many applications.

- The Progressive Cavity pumps allow only pumping a limited distance. It makes it limited to numerous applications.

- For longer distance applications, one needs to consult with the manufacturer itself or need to customize the design for the desired application.

- Since it is specially designed for high viscous fluids, the fluids with lower viscosity tend to slip from the rotor and stator assembly. This makes the pump less efficient in operation.

Applications of the Progressive Cavity pumps

The Progressive Cavity Pump is used to pump or transfer fluids that are impossible to handle by other pumps. They are typically used to serve the following impetus.

- Pumping and dosing of high fluids.

- In the processing of wastewater applications, since the wastewater has dust particles which can be considered as abrasive particles and thus other pumps fail to handle such kind of fluids and hence in wastewater processing progressive cavity pumps are used.

- In industries where food processes and beverage processing operations are conducted. These pumps are extensively used at such places.

- In oil pumping and petrol production industries since these pumps can work with high viscous fluids.

- Pumping of lubrication oil.

- Paper processing.

- In paper production as well cement and grout pumping industries.

- Chemical industries.

- Cement industries.

Conclusion

In this blog, as we have studied the construction and working of the Progressive cavity pumps, we can come to the conclusion that this pump has intricate yet very unique and reliable construction, which makes it much more exclusive for numerous operations. It allows one to use high viscous fluids, which makes it desirable for fluids such as oil, petrol, diesel, etc.

Also, its ability to use fluids with abrasive particles makes the progressive cavity pumps useful for wastewater and slurry operations. Furthermore, progressive cavity pumps are considered self-priming at instances and operate at high pressure than many other positive displacement pumps.

It also does have a high suction lift. And thus, the progressive cavity pumps will easily operate under different conditions as well as difficult operations, and hence it makes them more prudent than centrifugal pumps or any other pumps. Refer our YouTube Videos .

.

I’m extremely impressed with your writing skills as well as with the layout on your weblog. Is this a paid theme or did you modify it yourself? Either way keep up the nice quality writing, it’s rare to see a nice blog like this one today.|

Hi Lavonne,

Its ACABADO theme, one time paid only and you can make unlimited website. Thanks