In this article, we will learn what is an expansion valve in the AC system or refrigeration of the HVAC system along with function, types, working principle, etc. Let’s explore!

What is an Expansion Valve in AC & Refrigeration

Expansion Valve Basics

Let’s try to understand the basics of the expansion valve! Refrigeration and Air conditioning is a modern technology marvel, and we really take it for granted.

- We are surrounded by these devices and we really don’t know much of the details.

- Although compressor is known as the heart of AC & Refrigeration or HVAC systems while expansion valve, evaporator and condenser are also the equal importance to complete the system.

But many of us don’t know there is one part without which that exact condition of coldness and hotness we get would have been impossible. This device is called an expansion valve.

Expansion Valve Definition

It is this device that determines refrigerant flow rate which in turn gives desired temperature control.

- Its a component of the refrigeration cycle

- The basic part of AC & refrigeration system

- It makes the refrigerant flow in a steady condition

- It helps to expand the refrigerant and reduce the temperature to change the phase of the liquid gas mixture into gas.

Expansion Valve in AC & Refrigeration System

To understand the working of the expansion valve in the AC & refrigeration system, it becomes important to understand the temperature entropy diagram.

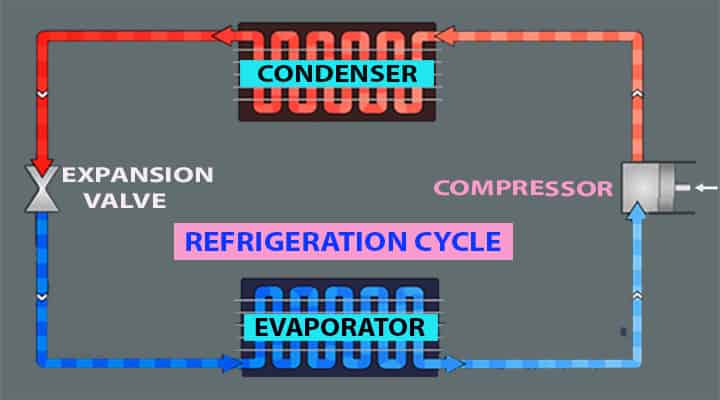

We have already learned the basic refrigeration cycle and understood that,

- Compressor, condenser, expansion device, and evaporator are four parts in a refrigeration cycle.

- The compressor compresses refrigerant, in this process refrigerant gets heat up due to increasing pressure and temperature.

- Due to this condition, it gets superheated.

- Now it is very much essential to cool so, it is circulated through the condenser.

- Condenser changes the medium of refrigerant by de-superheating and subcooled it based on the requirements.

- Then expansion device slowly reduces pressure and controls the mass flow rate of the system.

Lastly, the evaporator absorbs the outside heat of the cooling load brings down the temperature of the system to be cooled.

- 1-2 process in the above diagram shows compression process in the compressor

- 2-3’-3-4 process indicates the condensation process in condenser

- 4-5 process indicates the expansion process which is worked based on the capillary tube process.

- 5-6 process indicates evaporation process in which outside heat is getting absorbed by the evaporator.

- 6-1 process indicates the superheating before entering the compressor.

For us process 4-5 is important. The Vapour compression cycle is divided into two areas.

- From points 1 to 3 it is known as the high-pressure side while 3 to 6 is known as the low-pressure side.

- The expansion valve operates exactly between the two.

Its main job is to control flow rate and also reduce pressure. As we can see temperature drops from 4 to 5 can be seen from the above diagram, the temperature drop is accompanied by pressure drop.

It is a device that meters the flow of liquid refrigerant coming from the condenser and passes it to the evaporator.

What is the Function of Expansion Valve?

The main function of expansion valves in AC and Refrigeration shall be as follows,

- It has to reduce pressure of liquid refrigerant is coming from condenser.

- It has to maintain that pressure difference between high pressure and low pressure sides in vapour compression refrigeration system.

- Its capacity is determined by amount of mass flow rate it controls and maintains it throughout its operation cycle.

- It has to vary refrigerant flow, either increase or decrease as per fluctuation in loads.

Types of Expansion Valves

- Hand operated valve

- Low side float valve

- High side float valve

- Automatic expansion valve

- Thermostatic expansion valve

- Electronic expansion valve

- Capillary tube

Let’s go through the working of these expansion devices.

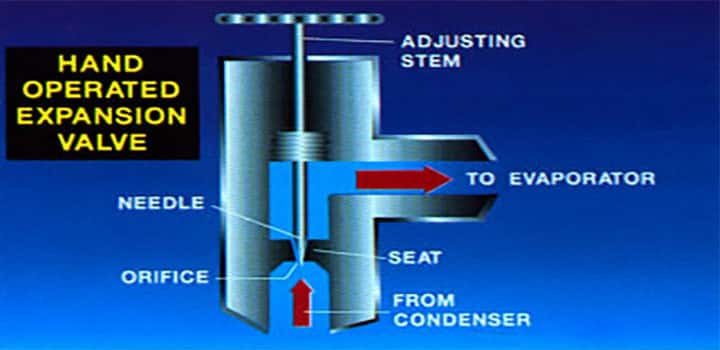

Hand Operated Expansion Valve

What is Hand Operated Expansion Valve?

As the name suggests this valve is operated manually by hand and hence mostly it is not used nowadays.

These valves are used where a constant refrigerant supply is to be kept for a long time. It is done manually as per the need and demand of the system.

Construction & Working Principle of Hand Operated Expansion Valve

It is very simple in construction, basically like our tap. It has a handle at the top to give feed which is connected to the center adjusting stem which has a needle at the bottom.

- When it is rotated it moves down and blocks the orifice from which refrigerant from the condenser is coming.

- This process leads to a reduction in the flow rate of refrigerants.

- When it rotated upwards, the stem moves up and the orifice is not blockaded giving more opening space to the orifice, and hence refrigerant flow increases.

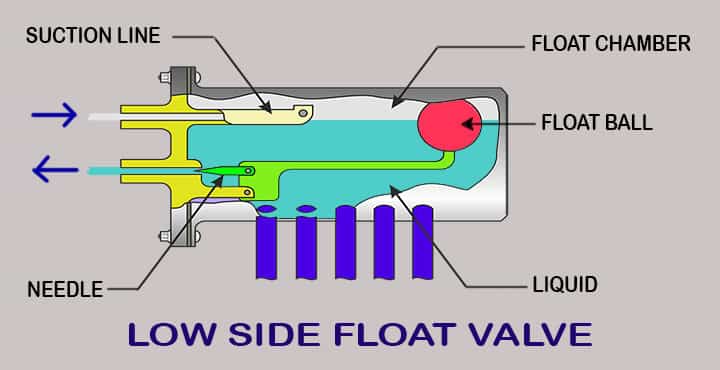

Low Side Float Expansion Valve

What is a Low Side Float Type Expansion valve?

As the name suggests it is placed on the low-pressure side of the system. It is placed in between the condenser and evaporator. Generally, it is attached to the evaporator itself.

- These are used large capacity refrigeration systems.

- It tries to maintain a constant level of refrigerant in a flooded type evaporator.

- It opens up when there is no liquid in the evaporator and closes when the required amount of refrigerant is in the evaporator.

Construction & Working Principle of Low Side Float Type Expansion valve

The whole system is placed in a hollow chamber. On its lower side, there is a liquid input line coming from the condenser while on the upper side there is an output line going to the evaporator.

- The float valve works on sensing done by the buoyant member.

- It opens and closes as per the position of the buoyant member called float.

- It is generally made by a hollow cylinder or a plastic ball. This float moves up and down as per the refrigerant level.

- The float ball is connected to the needle.

- When float moves down, the needle moves backward thus increasing the size of the orifice and hence increases the amount of refrigerant in the chamber.

- When float moves up, orifice size reduces and thus less refrigerant comes inside the chamber called as float chamber.

- Floats’ movement is dependent on the load of the evaporator.

- When the load on the evaporator increases, the float falls down while it moves up when the load on the evaporator decreases.

These valves are used in large capacity systems and a bypass line is provided to this valve which is operated by a hand-operated expansion valve just in case of float failure.

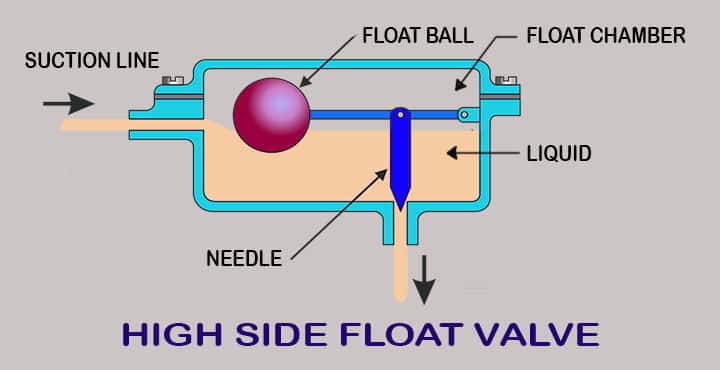

High Side Float Expansion Valve

What is a High Side Float Type Expansion Valve?

As the name suggests it is placed on a high-pressure side system. Its float chamber is attached to the condenser.

It tries to maintain a constant level of refrigerant in a floating chamber connected high-pressure side of the condenser.

Construction & Working of High Side Float Type Expansion Valve

The construction is very simple. Float made of plastic is connected to needle and orifice system.

- As soon as the load on the evaporator increases more refrigerant goes through evaporation and condensation.

- As a result, the liquid level rises in the float chamber, so in just instances, the needle operates to increase orifice opening and allowing to flow of more refrigerant.

- It controls the system such that fixed the amount of refrigerant is on the high-pressure side that is the condenser side whilst a large amount is provided to the evaporator as per load variations.

Applications

In flooded type evaporator.

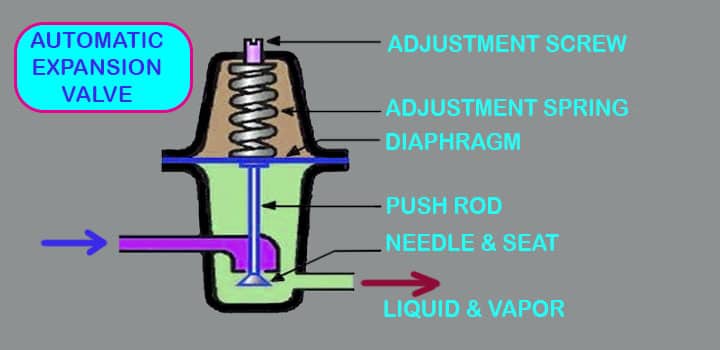

Automatic Expansion Expansion Valve

What is Automatic Expansion Valve?

As the name suggests, it is an automatic control system. It is used in constant pressure systems. It maintains constant pressure in the evaporator.

Construction & Working of Automatic Expansion Valve

Its design is a bit complex. The whole system is based on pressure sensing which is to be done by the diaphragm. As soon as the pressure changes on the diaphragm, a change in mass flow rate takes place.

- In a casing, at top, there is an adjustable screw which in turn is connected to the spring which is connected to the diaphragm.

- When the adjustable screw is moved, it presses spring which in turn causes movement of the diaphragm.

- Below the diaphragm, the needle is connected to it and at the extreme end is the orifice opening.

- Orifice opening separates valve into two-part, the lower part has an inlet of refrigerant coming from condenser while the upper side has an outlet of refrigerant going to the evaporator.

The needle moves up and down in this orifice there by controlling the mass flow rate. As soon as the diaphragm moves, the needle moves up and down and the opening of the orifice is controlled. Refrigerant comes from below

To understand working we need to understand pressure in this system. Refrigerant coming from the condenser is high pressure whilst evaporator is having low pressure.

- This expansion device is used to maintain constant pressure in the evaporator.

- So considering the diaphragm, P1 pressure is acting on it, which is fixed by adjusting the screw. So specific amount of mass flow rate is passing on it.

The diaphragm is always facing pressure from the evaporator denoted by Pe. When P1>Pe refrigerant continues flowing as per fixed value.

Situation 1- Increase in Load

But when load increases on the evaporator, which will cause refrigerant to absorb heat more which in turn will lead to rise in pressure.

This situation demands more refrigerant flow but as Pe>P1, the diaphragm will be pushed up and the needle will block the orifice resulting in a lesser mass flow rate which is exactly the opposite of what is needed to be done. While the compressor keeps sucking refrigerant, the evaporator becomes dry and its life gets affected.

Situation 2- Decrease in Load

The same can be said when the load on the evaporator decreases, the mass flow rate should be reduced. As temperature moves down, evaporator pressure reduces so P1>Pe, this results in diaphragm movement downwards resulting in more opening of the orifice which leads to flooding of the evaporator.

- Here mass flow rate should be reduced but exactly the opposite outcome is obtained.

- Valve provides more refrigerant to the evaporator than the amount compressor can remove from the evaporator.

- This results in the accumulation of refrigerant in the evaporator and is known as “flooding” of the evaporator.

- Evaporator gets filled and the compressor may overflow with it.

These two are limitations are of this valve. Hence its application is where constant pressure and constant temperature are needed to be maintained. Load fluctuation should not be there.

Application

In Milk chilling units and water chillers.

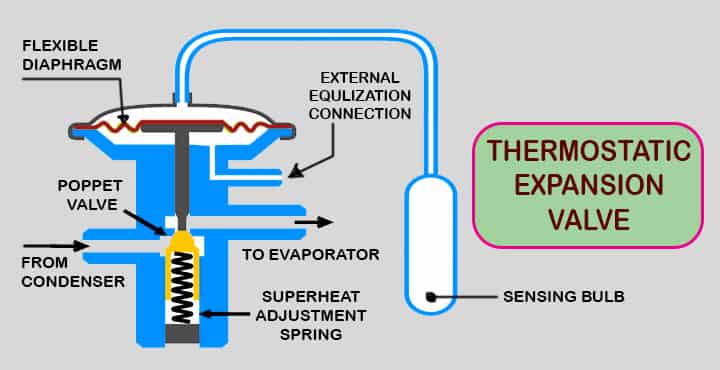

Thermostatic Expansion Valve

What is Thermostatic Expansion Valve?

This valve works based on temperature sensing. It tries to maintain a constant temperature in the evaporator. This is done by achieving a close loop system.

It tries to maintain a constant degree of superheat at the end of the evaporator so that the health of the compressor is prolonged by preventing slugging. This is a most versatile valve and hence commonly used.

Construction & Working of Thermostatic Expansion Valve

In casing at the lower end, there is one adjusting spring connected to the screw. At one end of the spring, the needle is connected which is closer to the orifice so as per movement it controls its opening.

- On the upper side, there exists a needle stand to which the needle is connected.

- Needle stand is connected bellows, bellows are like a spring element. They get compressed or get expanded as per pressure.

- Orifice opening separates valve into two-part, the lower part has an inlet of refrigerant coming from condenser while the upper side has an outlet of refrigerant going to the evaporator.

- The sensing element is placed in between of evaporator outlet and inlet of the compressor. In this case, a feller bulb is used.

Usually, it has the same refrigerant which is present in the system while in some cases other fluid is then such valves are called cross charge. Feeler bulbs are connected with a valve by a narrow tube and fluid/refrigerant in it is called power fluid.

Consider pressure Pf is exerted by power fluid on bellows, this is the pressure which compresses bellow to push them down so as to increase orifice opening by pushing needle down. ‘Pe’ is the force exerted by evaporator pressure on bellows which try to move the needle up and reduce flow rate. ‘Ps’ the fixed amount of pressure applied by spring to maintain a specific amount of flow rate.

Condition 1- Pf > Pe + Ps

This happens when the load on the evaporator increases causing high absorption of heat from surroundings. This causes an increase in the temperature and pressure of the system. The evaporator is on the low-pressure side of the system but in this condition pressure in it is increasing.

- Also refrigerant is super-heated, even though the end goal is to achieve but there is a limit to it.

- So mass flow rate must be increased, this is achieved as feeler bulb senses high temperature, its power fluid gets heat up and rise in pressure takes place and it starts to exert force on bellows which in turn push the needle down and increase the opening of orifice.

- This results in an increase in mass flow rate.

Condition 2 – Pf = Pe + Ps

This should be the end goal of the system to have continuous superheated refrigerant at the exit of the evaporator. But as soon as the mass flow rate increases temperature drops, and this is sensed by the feeler bulb which in turn affects the movement of bellows.

- This causes upward movement of the needle and reduces opening of orifice and mass flow rate is reduced.

- But our end goal is to keep at some specific value, this is done by providing balancing pressure in form of Ps.

- This spring force balances the whole equation to get a constant mass flow rate and correction has to be done only when the load on the system varies.

These are highly efficient but costly. They offer excellent control on mass flow rate and avoid slugging of compressor. Just one precaution has to be taken, the feeler bulb should have good contact with the evaporator.

Applications

Large scale refrigeration plant where automation is preferred.

Electronic Expansion Valve

As the name suggests, an electronic sensing device is used. This sensing device is called a thermistor.

Construction and working

The expansion valve consists of a heater coil to which the needle is attached. The needle is in front of the orifice and its up and down movement controls the flow of the refrigerant.

- This needle moves up and down based on the magnitude of current passing through the heating element/coil.

- When there is small resistance, it allows more current to flow through this heating element and the needle moves up and more refrigerant flows through the valve.

- The thermistor is placed in a series arrangement with the heater.

- A thermistor is placed just outside the evaporator where it senses the temperature of refrigerant coming out of the evaporator.

- The heater current is actually dependent on the resistance of the thermistor which is in turn dependent on refrigerant temperature. superheated vapor reduces thermistor resistance and hence more current flow through the heating element and the valve opens more allowing more mass flow rate to reduce to load on the evaporator.

- This will continue till the point where refrigerant coming out evaporator is saturated and will have some liquid droplets.

Then thermistor will sense the drop in temperature will have high resistance which in turn will reduce current passing through the heating element, and that will reduce needle movement downward, thus reducing the flow of refrigerant. As this valve is not dependent on refrigerant pressure and hence it can be operated in the reverse direction.

Applications

It is mostly used in year-round air conditioning systems, that way in winter when it works as a heat pump, it can be operated in the reverse direction.

Capillary Tube Expansion Valve

What is Capilary Tube Expansion Valve?

It is a tube having a very small diameter which is very long. Its size is between 0.5 mm to 3 mm and its length is up to 1 to 6 m. it is fitted in the system after doing heat load calculation. It is generally made of copper. It is wound up in winding to achieve maximum friction, thus pressure drops.

Working of Capilary Tube Expansion Valve

Pressure drop is achieved by friction offered by tube walls to flow of refrigerant. Mass flow rate is totally dependent on pressure difference drop and it cannot vary as per load fluctuations.

Applications

Small scale refrigeration system like household freezer and split AC.

Capillary Tube vs Thermostatic Expansion Valve

Let’s see the differences between the capillary tube and thermostatic expansion valve,

| Capillary tube | Thermostatic expansion valve |

| It is a long narrow winded tube. | It is an expansion valve actuated by a thermal sensing element. |

| Mostly used in small-scale applications. | Mostly used in the large-scale refrigeration system. |

| The pressure drop achieved is low. | The pressure drop is high. |

| The cost is low. | The cost is high. |

| A receiver is not required. | A receiver is needed in some cases. |

| Simple in construction. | Complex in construction. |

| It cannot change the mass flow rate of refrigerant. | It can very refrigerant mass flow rate as per load fluctuations. |

| It does not have moving parts and maintenance is not needed. | It does have moving parts and hence maintenance is needed. |

| Application – Split AC, Fridge | Application – central AC |

What Happens if Expansion Valve goes Bad?

We have already understood the basics of an expansion valve in AC and refrigeration systems. Now, let’s try to understand what happens if the expansion valve goes bad? The expansion valve regulates the flow of refrigerant flow based on requirements. If the load is more, then it opens more to flow more refrigerant and if the load is low then it opens less to flow less amount of refrigerant. Now, if the expansion valve fails, then the following scenario will come into the picture,

- AC and refrigeration system performance will be degraded as it cannot regulate the flow and it gives a constant flow whatever the load is required.

- If it continues, the performance will be worst.

- Power consumption will not be optimized.

- Compressor will be running continuously which will absorb more power and it will be heated gradually.

- Longevity of compressor as well as AC & refrigeration will be reduced.

- Refrigerant vapor enters into the evaporator may have refrigerant liquid which reduces the efficiency of evaporator.

- Warm air may be coming out due to inefficiency of evaporator.

- On the other way, it can make frost on the cooling coil as well.

Conclusion

Hence, we have got a basic idea about expansion valves, along with various types. Any doubt, please let us know.