In this article, we will learn what are V12 engines in cars along with parts, common problems, and applications. Let’s explore the V12 engine!

What are V12 Engines in Cars? V12 engine Basics & History

V12 Engine Basics

Let’s try to understand the basics of V12 engines in cars. One of the greatest inventions in humankind’s history is the Wheels. It has enabled the evolution to be on a fluid path. Gradually we have invented some of the things that keep us at the top of the evolution cycle.

- Automobiles are also among the class apart inventions.

- Some components provide the automobile with much-needed power, and among them, the engine acts as the heart.

- One cannot think about the existence of an automobile without an engine.

- It is essential to get all the information about the engines as it will lead to a better understanding of the automobiles and their efficiency.

- V12 engines are widely used in Lamborghini and Jaguar cars.

Here we will discuss one of the power-packed engines that make the difference in the automobile world. We are going to discuss the internal combustion engine that is widely known as the V12 engine. Here we will also provide the different components that make it quite efficient with its core operations. We will start with the information about the engine with its brief history.

History of the V12 Engines

V12 engines are the most compact, well-toned, low noise, and robust engines that have refined their core operation from the past. It was a tame beast in the past but gradually developed with some of the advancements.

- In the past, it was loud and used to roar with a bulky structure. In the past, V12s were not like the present engine as they were equipped with numerous flaws.

- An internal combustion engine is an engine in which the chemical energy of the fuel is being released in the engine and directly been used for mechanical work.

- It is different from an external combustion engine in which the fuel is burned in a separate combustor.

- Internal combustion engines were developed in the late 1800s and had a massive impact on society.

- It was considered the most significant invention in the world. The effect of these engines on society has made a mark.

- It had effectively changed all the sectors that are related to transportation.

- It also enables us to invent and improve the efficiency of automobiles, airplanes, trains, and trucks.

After the invention of the IC engine, Lamborghini introduced V12 engines in 1963 and it was called Lamborghini V12 engines. It was used in Lamborghini 350 GT car models.

After getting a brief overview of the history of V12 engine, let’s indulge in introducing the V12 engine, which makes us understand the core definition of the same.

Definition of V12 Engines in Cars

Let’s see the core concept of V12 engines. A V12 engine has got its name of V12 as it is equipped with 12 cylinders which is also an internal combustion engine.

- It is equipped with six cylinders on both sides, which are known as banks.

- The two banks acquire a structure of “V” shape. The banks remain at 60 angles to each other.

- There is a common crankshaft available for all twelve pistons.

- These engines can use operation with the help of different types of fuels such as gasoline, natural gas, and diesel.

- These kinds of engines don’t need a balance shaft.

- V12 engine banks can be at any angle and can easily work effectively.

Smooth running can be attained due to this, and also, for race cars, it can be made much lighter, which provides ample speed. In different kinds of heavy vehicles, they can also run at a slower speed which makes them suitable for all kinds of vehicles and aircraft. These engines are also apt for providing the last longing for life.

Parts of the V12 Engines

There are numerous components available in the V12 engine which effectively works for the whole operation and provide power-packed performance. The following re the elaborative analysis of the different parts of the V12 engine, which will help us in understanding the core working as well as the functions of each component:

Piston in V12 Engine

Function: This is among the prominent parts of the engine that effectively transfers force from the cylinder from expanding gas to the crankshaft through a connecting rod.

- The piston is one of the main reciprocating parts of an engine which and there is a probability of imbalance due to this.

- The piston has numerous components that are quite important for the engine’s functionality.

- These are piston pin bore, piston head, skirt, ring grooves, piston rings, and ring lands.

- Pistons are made up of cast aluminum alloy with outstanding lightweight and par-level thermal conductivity properties.

Working: The piston is used for transmitting the energy to the crank. The piston is attached to the connecting rod, which in turn is also attached to the crank. The linear movement of the piston is then converted to the crank’s rotational movement. This also leads to mechanical loss, which is quite evident.

Probable problem: The imbalance caused by pistons gradually transforms to vibrations which causes numerous problems for the engine; the friction between the walls so if the cylinder with piston may cause wear which in general reduces the life of the pistons and the whole mechanism.

- One major problem that persists due to the piston is its massive sound that can be quite intolerable.

- Ultimately the engine experiences a substantial loss in the overall efficiency of the whole combustion process.

- Sometimes minimal or maximum clearance will be there; both of them are lethal for the engine’s proper functioning.

- It is recommended to attain proper clearance to cause any problem regarding the piston movement and noise.

Piston Rings in V12 Engine

Function: A piston ring is an elastic split ring used to seal the pistons on the cylinder wall. These are made up of cast iron as it is the material that easily retains its actual properties when to undergoes load, heat, or any force.

Working: Piston rings effectively seal the combustion chamber and also helps in conducting heat from the piston to the wall of the cylinder as well as helps in returning the oil to the crankcase.

- The size of the ring pistons depends on the engine design and the material of the cylinder.

- There are different piston rings, such as wiper rings, compression rings, and oil rings.

- The compression ring is used to seal the combustion chamber, which restricts it from leakage while the combustion process occurs.

Probable problem: Numerous problems are prone to the engine.

- The problem of breakage, as well as slippage, is the foremost ones.

- One cannot expect to perform DIY for these problems.

- If there is any problem persisting related to piston rings, it should be changed simultaneously with the help of expert professionals.

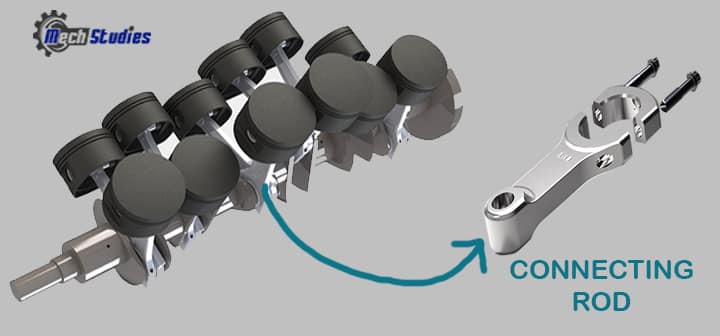

Connecting Rod in V12 Engine

Function: The connecting rod is the most important linkage inside the combustion engine.

- It attaches the piston to the crankshaft and gets it to acquire power from the piston to the crankshaft and ultimately to the transmission.

- These are manufacturers with different kinds of materials.

- The most common of all are aluminum and steel.

- The processes through which these are manufactures are forging, casting, and powder metallurgy.

Working: The core work of the connecting rod is to provide a linkage between the piston and crankshaft. When it comes to the V12 engine, the connecting rod should be made up of effective material that can withstand the same power-packed performance.

Probable problem: The probability of getting excessive wear and tear is the most major problem due to the excessive harmonics.

- It is quite prominent that the failure of connecting rod can cause massive problems to the engine.

- It is prescribed to provide special care to the connecting rod as excessive load pressure can cause premature failure.

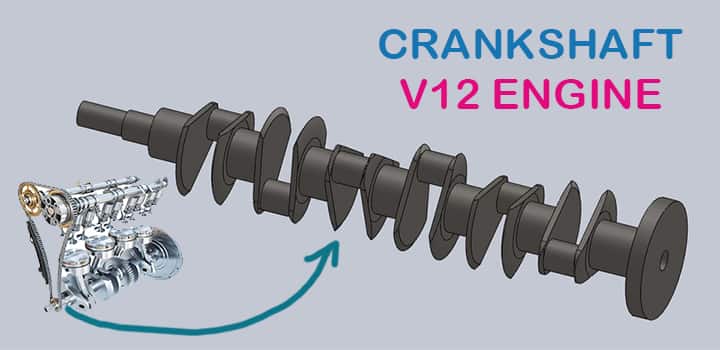

Crankshaft in V12 Engine

Function: The foremost function of a crankshaft is to convert the reciprocating linear piston motion into rotational

Working: The core working involves the crankpins in which the additional bearing surfaces are in the offset direction to which the big ends are attached and provide a rotational movement. The crankshaft remains attached to the flywheel, which decreases the pulsation characteristics and vibrational or torsional dampness.

Probable problem: There is a problem that is quite lethal.

- It is mandatory to make the snout of the crankshaft very strong to withstand the stress of the pulley places.

- It is effective for driving all the components effectively.

Camshaft in V12 Engine

Function: We can call Camshaft as the CPU of the engine. It acts as a brain for the engine because the core job of the camshaft is the opening and closing at an exact time during the rotation.

- This enables the engine to attain a par level of power and effective cleanout of exhaust.

- It helps in driving the distributor, which in turn synchronizes the spark ignitions.

Working: The camshaft is responsible for driving the distributor to make sync to spark ignition electronically.

- Camshaft’s mode of operation depends upon the actuation of the components of the valve train.

- The crankshaft drives it with the help of a set of gears or belts, or chains.

- The camshaft operates the lifters that operate the valve train, essential for the engine’s functionality.

Probable problem: The probable problems in the camshaft can be related to different mechanisms as they come in different structures and are manufactured of different materials.

- The most popular and common ones are mechanical, roller, and hydraulic roller equipped.

- In the camshaft, movement fault is probable; however, this is quite low as they are quiet and don’t require timely adjustment.

Applications of the V12 Engines

There is a vivid use of the V12 engine due to its power output and maximum efficiency. Numerous sectors use these kinds of engines extensively. In this part of this excerpt, we will grab a fair share of information about those sectors and the most probable reason that makes V12 engines appropriate for use. Without any further ado, let us delve into those sectors which use V12 engines.

Fighter and bomber aircraft: The use of the V12 engine was prone to fighter and bomber aircraft in the past. The structural design of V12 engines with optimal performance makes them quite suitable for high-performance aircraft. The configuration of V12 engines makes them quite suitable for aircraft performance.

- In the past, the V12 engine has a short and wide radial engine.

- During World War II, the excessive power of these bomber aircraft has increased substantially to extreme levels.

- It was quite appropriate for lightweight aircraft as it provided them stability and excessive power.

- However, the V12 engines were gradually replaced by Turboprop and turbojet engines, comparatively more power-packed and vibrationless.

Locomotive and battle engines: V12 engines are also commonly used for battle tanks and locomotive engines because of the massive power generated. However, the engine’s width is minimal in railway clearances, and the length of these vehicles is quite long.

- Apart from that are also used marine vehicles where there is a need for great power and where the hull width is limited.

- These are also used in twin-propeller boats, which may use multiple ones.

- Numerous fast cruise ships use the V12 engines.

- Massive cruise ships can be equipped with numerous engines, which can go up to six or more.

Aviation industry: The first use of the V12 engine was in aircraft. V12 engines were quite popular among the aviation industry after world war I.

- One of the most famous aircraft that use V12 engines are zeppelins which makes this quite successful.

- Apart from that, numerous brands specifically provided V12 engine powered aircraft to Britain in the battle of Britain.

- One of the main reasons that make the V12 engine class apart is its long and narrow configuration which provides the optimal aerodynamic properties.

- Apart from this, the par level smoothness makes it quite effective for aircraft equipped with fragile and light airframes.

However, the V12 engines were gradually replaced by turboprop and turbojet engines, modern technological advancements. These engines are apt for producing the optimal level of power and minimal problems for the aircraft.

Common automobiles: The use of the V12 engine is quite widespread in road luxury and high-end sports cars due to the massive complexity in the structure and the associated cost. These are used in sports and luxury cars due to their power, class apart sound, and low vibration. Lamborghini V12 engines and v12 engine jaguar

V12 engines and v12 engine jaguar are examples of V12 engines.

are examples of V12 engines.

Racing cars: The history of the use of V12 engines in racing cars is quite vivid. This is quite popular in Formula one and different endurance racing such as NASCAR and many more. However, the continuous improvement in the engine segment makes it less popular amongst the racing genre.

- There are numerous factors due to which the V12 engine has been stopped from the racing circuit.

- It has become more evident when the racing industry has got some of the small, lightweight engines in place of bulky V12 engines.

- However, there are numerous vehicles present which currently use V12 engines.

- The innovations in the engine were designed to produce maximum power according to their weight.

- Thus the use of new engines over the V12 engines is justified.

Most Common Problems of V12 Engines

The V12 engines were popular for their power-packed performance as well as their efficient operation. These are pretty powerful engines, but some complications make them relatively ineffective. There are some of the common problems that persist in these engines. It is because the V12 engine fires six times a cycle, which needs proper synchronization of the engine components. When the V12 engine runs, it provides a smooth ride, but when any defects come, it may take massive time to fix the same.

01. Leakage of hydraulic fluid

This is one of the common problems in any V12 engine, which is a clear sign of vehicle inefficiency, malfunctions, and poor efficiency.

- This problem persists due to numerous reasons though this can be easily noticed as one can easily get the look for the leaking fluid beneath the automobile.

- The amber hue appearance is also helpful in detecting hydraulic fluid leakage.

02. Misfiring of engine

Misfiring of the engine or engine stalling can be a very demeaning problem to encounter.

- The probable reason for this can be a faulty air flow sensor due to the vacuum leaks or dirt clogged air filter, blown gasket, or jammed fuel injectors.

- These can easily cause the engine to stall.

- However, engine misfiring is not that much of a problem as it depicts the need for engine servicing.

03. Overheating of engine

There are numerous reasons which can lead to V12 engine overheating.

- The probable reasons can be a blown gasket, leakage of coolant, or any of the small malfunctions that can easily cause the engine’s overheating.

- It is recommended to take the vehicle for professional help when there is a slight possibility of overheating the V12 engine.

- It takes very little time to cure the overheating of the V12 engine, but it can take extended hours in some cases.

Critical Engine Parts Need to Taken Care while performing DIY

Engine issues can occur for many reasons, so it is essential to practice safe driving methods, especially with an engine as powerful as a V12 engine. If you are going for DIY for the above problems in your V12 engine, then it is recommended to keep a keen look at the following items, which can be a major issue if not considered critically. It is also prescribed to use different protective equipment while catering to the problems of the engine.

Spark plugs

The V12 engine has 12 spark plugs, and if there is a problem with spark plugs, one has to check all of them.

- It is recommended to wear protective gloves while diagnosing the same.

- If any of them has hue coloring, it is clear that it is getting massively hot or not getting hot enough.

- This is a sign that depicts the engine stalling or misfiring of the same.

- It is recommended to change some or all the spark plugs in case of old vehicles.

Wires of spark plug

It is recommended to check the wires but with proper care. It is quite evident that sparks can be there.

- The probable reason for taking utmost care is the availability of water in the vicinity.

- If anything sparks, then it is the sign to change the whole wire.

- Next, it is prescribed that we should check the wires for cracks.

- Most of them are equipped with a date that can depict the time of the wire.

- Wires are parts that are not that expensive and can be replaced without any delay.

- There is one more sign that can help in getting the proper look of wire is the squeezing.

- It can easily depict the condition of the wire.

Ignition Coils

This is one of the parts that need proper knowledge. If you want to perform DIY, then it is recommended to take proper care. To cater to this, we need to check every coil with some pieces of equipment, such as an ohmmeter. If there is something faulty, you will need to change it, but if there is no fault, we can check the other components further.

Fuel Injectors

This is one of the complicated components of an engine that can only be cured with the help of professionals.

- Fuel injector problems in any V12 engine can be mind-numbing and time-consuming.

- Testing and pulling out the fuel injectors is a big task.

- The preferred way to cure this is to hand over your vehicle to certified technicians.

Conclusion

With the above applications of the V12 engine, it is pretty clear that these are powerful and efficient engines. However, the continuous improvement in the engines makes them obsolete gradually. Here we have emphasized different aspects of V12 engines, which provide us holistic knowledge about the same. This excerpt holds the core information about the various essential components that makes it quite efficient. Apart from that, we have already provided the core definition of the V12 engine with the operational procedure. However, there is a plethora of information about these engines, and we will analyze the further details in other excerpts.