Let’s learn about shaper machines along with it’s definition, brief history, need, types, principle, working, mechanism, advantages and disadvantages, etc. In the manufacturing sector, it is crucial to get a smooth finish of any yield material. Whether you are manufacturing a small bolt or a massive shaft, the finish of the material remains at the top that helps in grabbing exposure and remains in demand. Let’s explore Shaping Machines, its details.

What are Shaper Machines?

Shaper Machines Basics

What are shaper machines? Different machines can help in shaping the desired material. One of them is a shaper machine that is widely used for producing,

- vertical,

- inclined, or

- horizontal flat surfaces of a workpiece.

Shaper machines are one of the basic tools that hold an important place in any mechanical workshop.

Apart from that, it is also a vital part of the manufacturing industry. This machine is useful for manufacturing different parts, jobs, etc. Let’s delve into the brief information about machining tools and all-around information of one of the efficient machining tools, i.e. shaper machines that will help to understand the need for flat surfaces in an elaborate manner.

Shaper Machines Concept

A machine tool is nothing but a tool that helps in attaining a specified shape of any rigid material or metal. It is as same as a woodworking shaper that provides a smooth and flat surface to the wood whereas the shaper machine is responsible for providing a smooth surface to the metals.

- In most of the manufacturing processes, the use of metalworking planer is abundant.

- The shaper machine is also like the same, but the significant difference is the size and the process.

- In the shaper machine, the tool moves for shaping the workpiece while in the metalworking planar the job moves.

Shaper Machine Definition

A shaper machine is a machining tool that works on the principle of reciprocation.

- This tool is used for producing horizontal, vertical, or inclined flat surfaces.

- It works explicitly on straight line reciprocating single-point cut that provides yield surface as same as the lathe machine.

- The shaper machine is one of the machines which work by using the relative motion between the cutting tool and the workpiece.

- That machine cuts in a linear tool path and has linear motion.

The operation is the same as the lathe machine, but the lathe machine provides a helical-cut, whereas the shaper machine provides a linear cut.

History of Shaper Machines

The invention of the shaper machine tool took place in 1791. This is one of the common tool of the 19th and 20th century in the manufacturing industry. In the current time, there are different kinds of machining tools or equipment available that work the same as a shaper machine. A milling machine, grinding machine, CNC machines, or CNC milling machines are the advancement that can be used in the place of a shaper machine.

Although we are going through various technical innovations and advancements, the importance of the shaper machine remains at the top as the shaper machine provides a cut to the workpiece perfectly. This machine is entirely redundant and requires less maintenance.

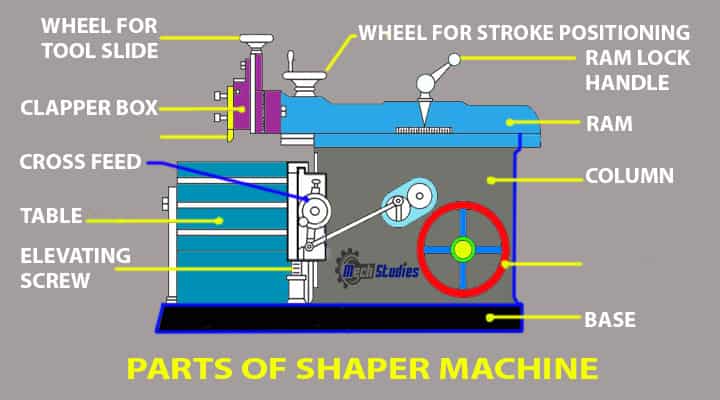

Parts of Shaper Machines: Explore its Components

It is crucial to get information about the different parts of the shaper as it helps in understanding the working of this machine. There are five vital parts of this machine. Following are the brief description about the same:

- Base

- Column & Guideways

- Cross rail

- Table & Table Supports

- Ram

- Tool head

- Clapper Box

- Vice

Let’s try to understand of all parts one by one,

01. Shaper Machine Base

The base is among the most necessary parts of any machining tool that provides support to the machine.

- The base of the shaper machine is made up of cast iron, and it is a hollow section.

- This helps in resisting the vibration.

- Every part of the shaper machine is mounted on the base.

- It is designed to withstand the entire load of the machine and helps in the set-up of cutting tools.

02. Column & Guideways

This is a box-like structure that is mounted on the base which is made up of cast iron.

- The column consists of two precise machined guideways which are located on the top of the column.

- The ram reciprocates on these guideways.

- The main working of this column is like a cover for the drive mechanism.

- Additionally, it supports the work-table as well as the reciprocating arm.

03. Cross rail

Cross rail is the part of the shaper machine which is situated on the front vertical surface of the column. The saddle is mounted on the cross rails.

- Cross rail helps in vertical movement, which can be manipulated by elevating screws.

- It also helps in the horizontal direction with the adjustment of the crossfeed screw.

04. Table & Table Supports

The table is among the vital parts of the shaper machine as it is bolted to the saddle.

- It receives vertical and crosswise movements from the saddle cross rails.

- For clamping, it uses explicitly T-bolts on the sides and top.

- The table is capable of swiveling at any desired angle.

- Table supports help the table to slide in vertical & crosswise movement in the guideways.

05. Ram

Ram is the part of the shaper machine that helps in the reciprocating action and also carries the tool head.

- The tool head is equipped with a single-point cutting tool.

- It helps in providing a desired depth of cut with the help of a down feed screw.

06. Tool Head

In the shaper machines, the cutting tool firmly holds for operation by a tool post. This tool head consists of a tool post as well as the cutting tools.

- Generally, a single-point cutting tool is held by a tool post.

- Cutting tools can be different depending on requirements.

07. Clapper Box

The cutting tool needs to be fitted into the tool post. Now, clapper box comes into picture for this regards.

- During the return stroke, it helps to provide sufficient clearance for the tool.

- During this clearance in the return stroke, there will not be any dragging force on the workpiece.

- It helps to prevent wear in the return stroke.

08. Vice

Vice is a part that is mounted on the table and it has movable & fixed jaws.

- Vice helps to hold the workpiece.

- Due to movable jaw, it can hold the workpiece of different sizes.

How Does Shaper Machines Work? Working Principle & Mechanism

The shaper machine works on a specific principle. Below mentioned is the basic principle and brief working of the same:

- The shaper machine consists of a ram that holds the single-point cutting tool and the workpiece is fixed over the vice or table.

- The tool attached in the ram provides a reciprocating motion over the job or workpiece, and the metal is removed in the forward stroke.

- This forward stroke is also known as cutting stroke.

- In addition to this, the return stroke or idle stroke doesn’t cut down any metal from the workpiece.

- The feed is dynamic and can be given at the end of the cutting stroke.

- The basic principle for the cutting of metal involves the slow rate of speed of cutting stroke while the return stroke experiences high speed.

- This quick return mechanism helps in reducing the overall cycle time and increases efficiency.

- There is another mechanism also on which this sharp machine cuts the metal. This is known as the Quick return Motion Mechanism. In this mechanism, the slider moves fast and cuts the material from the workpiece. In addition to this, the speed of return stroke is faster than the forward stroke, and it takes less time to return.

- The reciprocation motion of the ram cuts down the material and helps in acquiring the required shape of the metal. It is quite evident that in any mechanism, the return stroke doesn’t cut any materials.

- In a nutshell, it can be said that in the shaper machine, the essential operation is through the reciprocating motion of the ram holding the tool which is attained through the rotary motion of the drive.

The above are the basic principles and mechanisms on which a shaper machine works. It helps in understanding the core working of the machine.

Types of Shaper Machines: Explore Different Kinds

When it comes to different types of shaper machines, it depends upon the different parts. The kinds of shaper machines can be defined on the basis of essential parts such as mechanism, ram travel, table design & cutting stroke.

| Types of Shaper Machines | Names |

| According to driving Mechanism | Crank type shaper Gear type shaper Hydraulic shaper |

| According to Ram Travel | Horizontal shaper Vertical shaper |

| According to Table Design | Standard shaper Universal shaper |

| According to Cutting Stroke | Push cut shaper Draw cut shaper |

The following are the brief description about the same:

Description of Shaper Machine Types

Based on the Type of Driving Mechanism

Driving mechanisms are the most crucial aspect of a shaper machine. Based on the driving mechanism, there are three types of shaper machine.

Crank Type Shaper

These are among the commonly available shaper machines which provide machining action by holding the work piece on the table.

- The tool works in reciprocating motion as per the length of the stroke needed for the machining.

- The job is clamped in a specific position on an adjustable table.

- This shaper machine works on the principle of providing a crank mechanism that changes the circular motion of the large gear.

Gear Type Shaper

Gear type of shaper machine works with a ram working in reciprocating motion.

- The ram gets the desired motion due to motion with the pinion and rack.

- The usage of this type of shaper machine is limited and has no industry-specific use.

Hydraulic Shaper

The reciprocation motion in these types of shaper machines is due to the hydraulic mechanism.

- It uses oil under high pressure.

- The high-pressure oil acts on the side of the piston, which causes the movement of the other side of the piston.

- The essential advantage of this kind of shaper machine is the constant force of the ram drive and cutting speed.

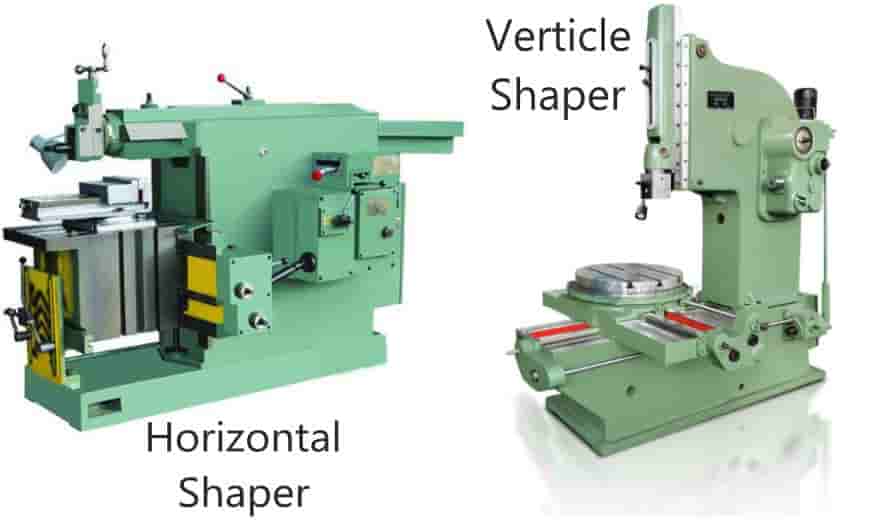

Based on Ram Travel

Ram is one of the vital parts of the shaper machines. Due to this part, the whole machine is capable of providing the reciprocating motion, which in turn helps in the machining process. There are two types of shaper machines based on ram travel.

Horizontal Shaper

The horizontal shaper machine holds the ram in a horizontal axis and provides a reciprocating motion. The primary use of this type of shaper machine is for the production of,

- external grooves,

- flat surfaces,

- keyways etc.

Vertical Shaper

In this type of shaper, just the position of the ram is in the vertical plane. The work piece is attached to the table in this kind of shaper machine.

- These types of vertical shaper machines depend upon different types of machines such as screw-driven, crank-driven, or even hydraulic mechanism-driven.

- These are effective for machining mainly internal surfaces such as slots, grooves, keyways, etc.

Based on the Table Design

These are some of the types of shaper machine based on the table design:

Standard Shaper

The standard shaper machines are equipped with only two movements, horizontal and vertical for providing the feed. In this shaper machine, the table doesn’t support the outer end.

Universal Shaper

As the name suggests, this shaper machine can provide all the movements, including inclined and angular ones.

- In this, the workpiece can be adjusted in different planes which provides a reason for its name “Universal”.

- This kind of shaper machine is widely used in all types of tool room works.

Based on Cutting Stroke

The reciprocating action of the ram in the shaper provides two strokes, cutting stroke and return stroke. There are different kinds of shaper machines based on cutting stroke.

Push cut Shaper

These are the kind of shaper machines in which the material is removed in the forward motion of the ram. It is among the commonly used shaper machines.

Draw cut Shaper

This kind of shaper machine removes the metal in the backward motion of the ram. In this shaper machine, the tool is fixed in the reverse side, which in turn provides the desired cutting action in the backward motion or reverse stroke of the ram.

Different kinds of Operations

The shaper machine is capable of providing four primary operations that makes it an efficient machining tool. Here we are providing a brief picture for all of those operations:

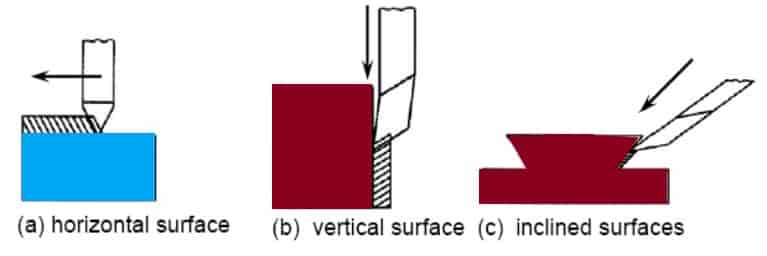

Inclined cutting

In this operation, the shaper machine provides an angular cut to the vertical or horizontal right angle to the plane.

Vertical cutting

This kind of cutting is achieved by machining a shoulder or squaring up a block which ultimately provides machining action to the end of the work piece. In this machining operation, the table doesn’t move vertically.

Horizontal cutting

In this cutting, the horizontal surfaces are machined. Additionally, the job mounted on the machine tables keeps on moving, concerning the ram movement of the shaper machine. This method is efficient as the tool automatically lifts during the return stroke, which prevents the drag of the machined surface.

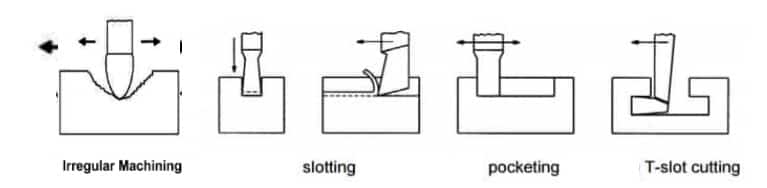

Irregular cutting

Irregular cutting is among the ambiguous operations of the shaper machine in which the round nose tool is used. Using this one can provide shallow cuts also.

Slots, Keyways & Gear Cutting

The shaper machines can cut in equal distance based on the settings of the cutting tool as well as the feed mechanism.

- It can cut like slots.

- It can make keyways like internal or external keyways.

- gear cutting can also be done by shaper machines based on the same philosophy.

Specification of Shaper machines

The below data needs to be known as the specification requirements of a shaper machine,

- Model number

- Size of the machine

- Length of the Ram

- Width of Ram

- Maximum stroke length

- Size or working area of table

- Length of table top

- Width of table top

- Length of table slide

- Width of table slide

- Distance between Table to Ram (Maximum)

- Vertical Travel of Tool post (maximum)

- Length of the cross slide

- Nos of Speed

- Power requirements

- Overall size (length x width x height)

- Weight

Applications of Shaper Machines

There is a different efficient application of a shaper machine specifically where there is a need for machining or carving different shapes. Some of them are discussed below:

- It is used for machining flat and straight surfaces.

- It is also used for machining the different kinds of internal splines and gear teeth.

- This machine is also used for dovetail sliders.

- Apart from all of the applications, getting the smoothness of a rough surface is among the best applications.

- It helps is electric discharge machining.

- It is one of the machines that can provide effective results where different kinds of machining or milling tools fail, precisely where there is a need for irregular holes in intricate corners. This machine is capable of creating those types of holes.

Advantages of Shaper Machines

There are numerous advantages to a shaper machine. Here we are providing some of the main ones:

- One of the most practical approaches by using this tool one gets is the low-cost machining. This single point cutting tool machine is available abundantly and is inexpensive.

- It provides efficient machining and doesn’t incur an additional cost.

- The efficiency and accurate stopping point of the cutting stroke provide massive benefit in gaining preciseness.

- It has easy to handle approach which is among the most significant advantages.

- It can be used for any angular or flat surfaces.

- It doesn’t cause any additional problem in the machining.

Disadvantages of Shaper Machine

Apart from some of the significant advantages, some limitations should be considered in getting a holistic knowledge of the machine. Some of them are as follows:

- It requires more time for machining as there are two strokes while machining. The cutting and return strokes increase the time substantially.

- This machine has only one tool.

- It doesn’t provide help in cutting the work pieces in both directions.

- The cutting speed

is shallow in the shaper machine.

is shallow in the shaper machine.

Manufacturers of Shaper machines

There are many manufacturers available for shaper machine, few of them are listed,

- Mitsubishi Heavy Industries

- Bourn & Koch Inc.

- Liebherr

- DVS Technology

- DSMM

- Star SU LLC

- R.P Engineering

Conclusion

Here we have emphasized one of the ordinaries yet useful machining tools that have massive importance. With the knowledge of its mechanism, operation, working and types, it is relatively easy to get an understanding of the same. In addition to most of the other things, the advantages and disadvantages clear the air regarding the efficiency and working of the machine. Apart from the above information there are a lot more to learn about shaper machine.