In this article, we will learn what is engine block along with the basic definition, meaning, different parts of the engine block, types, applications, etc.

Let’s explore!

What is Engine Block? Definition & Meaning

Let’s try to understand engine block with basics, definition & meaning.

Engine Block Basics

Let’s get into the basics of engine block! Engines are an integral part of an automobile built with ultimate precision, and the configurations are readily changing. This is because humankind continuously looks for better performance through continuous growth in technology.

The constant changes like drive-by-wire throttles, electronic fuel injection, and deactivation of cylinders have made the engine’s power and performance-oriented. The use of more robust and lightweight components makes an impact on performance.

- With the advent of the engine, we have gained a massive advantage. The engine is the most prominent part of an automobile as it acts as a core mechanism.

- Numerous subsidiary parts remain integral parts of the engine.

- These parts hold their specific place for the effective working of the engine.

- Here we will discuss one of the core components that act as an effective one as most of the engine’s functioning depends on this.

- This component is among the most vital components of the engine that acts as a housing for numerous parts.

- Engine blocks are effectively the core components that act as the covering body inside the engine. We will analyze some of the immensely popular materials and widely used for manufacturing cylinder or engine blocks.

Let’s start with the simple definition of engine or cylinder block.

Definition of Engine Block

An engine or cylinder block of the engine acts as the core of the engine. In this, most of the components which help the engine to work more efficiently are being housed.

These components are pretty vital and help the engine to function properly. This block is arranged in a “V” shape like V8 or V16 etc. or a flat configuration. The number of cylinders can lie between 3 to 16.

- Numerous common components are found in an engine, such as camshafts, pistons, rocker arms, timing chains, etc.

- When we dismantle all of that, you can find an engine or cylinder block right in the middle of the engine.

- The strongest engine component helps provide proper housing and protection to hundreds of parts found in any engine.

- Modern engines are quite complicated and contain comparatively more parts housed inside the engine block.

- This is a large component that easily occupies 20-25% of the whole weight of the engine.

- With technological development and continuous advancement, reducing the weight of engine blocks is gaining popularity.

XPH is your home for BMW, Audi, Ford Mustang, VW, Porsche and Nissan GTR aftermarket parts.

Function of Engine Block

There are numerous functions of the engine block that makes it quite an important component of the engine.

We will discuss each of them with proper reasons:

- One of the most important applications of engine blocks is to reduce the wear at the cylinder region, known as TDC or top dead center. The probable cause of wear at the TDC is due to the insufficient oil film at the point.

- It also occurs due to the scratch that occurs due to the continuous movement of the piston along with the distance on which it travels.

- The engine cylinder’s basic work is to check the straightness and roundness of the piston during the operation.

- Engine blocks are manufactured in this way that it helps in reducing the wear on the cylinders that occurs due to the scratch along the piston travel direction.

- Generation of power output is also an important function of the engine block.

- The core need for an automobile is the high amount of power output that makes it quite efficient.

- It occurs with the continuous generation of heat in the engine, which needs an optimal cooling unit compared to a lower-powered output engine.

- Cooling is a big factor in these kinds of engines, but the engine is not available in simpler designs as the engine blocks are not equipped with water passages.

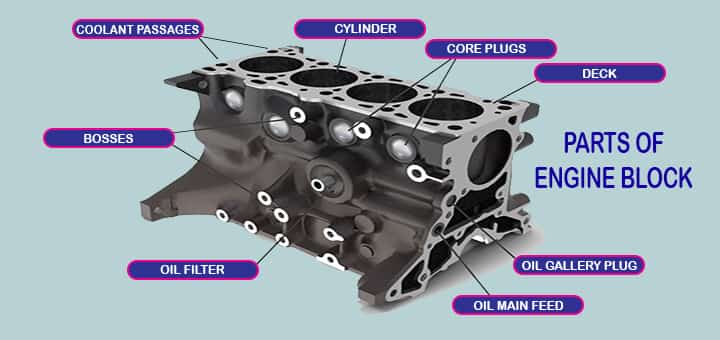

Parts of Engine Block

There are numerous components of engine blocks that make it run effectively. The function of these components is quite efficient as these are the ones that make the whole cylinder or engine blocks functional.

Here we are describing each of them briefly:

Deck

The deck is the top or upper surface of the engine block where the cylinder’s endpoint lies.

Crankcase

This is the housing for the crankshaft, which is situated beneath the engine or cylinder block.

Cylinders

These are the main part of engine blocks in which the piston movement takes place. These are mainly equipped with holes that are large and effectively help the piston to seal. The power and size of the engine critically depend upon the number of cylinders available in the engine block.

Spring is here! Save big on our best-selling WAGNER TUNING BMW F CHASSIS N55 CATTED DOWNPIPE

Galleries and passages for lubrication

These are among the prominent components of the engine block that mainly helps in the engine’s lubrication; with these galleries and passages, the oil transfers to the crankshaft and the cylinder head.

Head studs

Head studs are the parts of the engine blocks manufactured with the help of a circular rod made up of alloy steel. In the head stud, the threads are available, which helps in the tightening fitting of the block that effectively helps in reducing the probability of loosening the stud when the nut is extracted.

Core Plugs

This component acts as the cap of the cylinder block, which is present at the bottom of the coolant passage. The core function of this core plug is to reduce or prevent the leakage of coolant or water from the engine.

Water Pump Mounting

The water pump is available on the sides of the cylinder or engine block, combined with the casing of the coolant or lubrication.

Oil Filter

Oil filters are the components situated under the engine block or on the flank of the cylinder block. The main functions of oil filters are to prevent the lubricant from getting contaminated. It keeps the lubricant clean which also helps in the efficient circulation of the same.

These are the parts that are commonly available in an ideal engine block. Without these parts, we cannot imagine any of the cylinder or engine blocks construction. However, in the modern engine blocks, some additional parts are added to make them more efficient.

Types of Engine or Cylinder Blocks

The engine or cylinder blocks are divided based on the size of the engine cylinders. The following are the three main types of engine or cylinder blocks:

Engine blocks are classified according to the size of the engine cylinders.

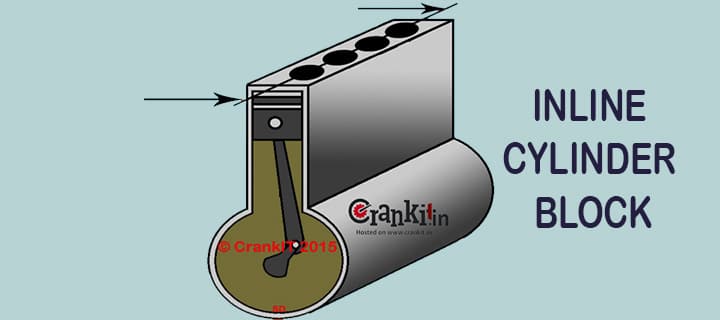

- Inline cylinder blocks

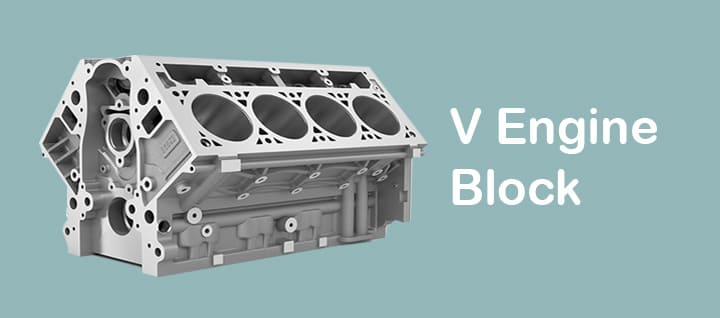

- V-engine cylinder blocks

- Opposed engine or Boxer engine cylinder blocks

Inline cylinder blocks

Inline cylinder blocks are the type of cylinder blocks in which the cylinders are arranged in a series. In this kind of block that cylinders are arranged to work in a single line.

This is among the blocks that make the running of the vehicle quite smooth. Where there is a need for high revolutions per minute, these blocks are used.

V-engine cylinder blocks

V-engines are modern engines, and these are widely getting used at present. The engines blocks or the cylinders are situated in two rows.

In these, there is a specific angle attained on which these two rows are placed.

The core functionality of this is to provide maximum balance to the engine. These blocks are used in small motorcycles.

The advantages of an inline engine block over a V engine block

Inline Engine

The inline engine’s primary limitation is this. As all the cylinders are arranged in a row, inline engines have a simple layout. Inline engines are more cost-effective and easier to maintain from a production perspective. Lack of space can make mounting a larger inline engine difficult. This is why inline engines typically have six cylinders, with a maximum of eight cylinders.

V Engine

Counterweights balance the performance of the V engine, adding complexity. It occupies less longitudinal space & allows for the addition of more cylinders.

The V engine is shorter but has a wider size, so there is less space on the side for accessories such as turbo mode. Because the V engine has two banks of cylinders, it requires more production parts, including a longer timing belt. A higher cost is associated with manufacturing and maintenance.

Despite their complexity, V engines remain in high demand. Smaller cars can easily accommodate the engine due to its compact size. Because of their flexibility, V engines can be used on a wide range of platforms, regardless of the vehicle’s size.

To wrap it up between the inline & V engine comparison, you can say that the inline engine is smoother, no noise & produces more power in the same amount of cylinders. But the V-engine is boosted by more cylinder addition.

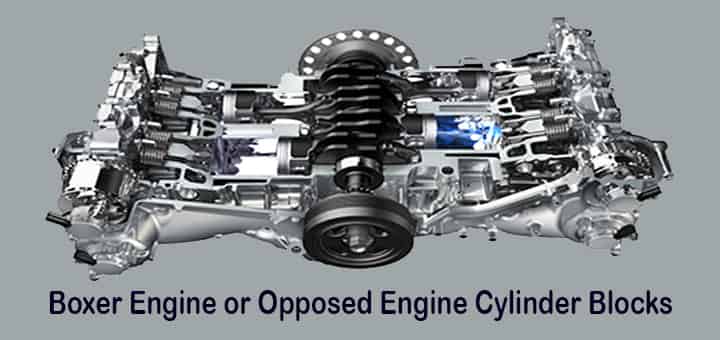

Boxer Engine or Opposed Engine Cylinder blocks

The boxer or opposed engine cylinder blocks are the blocks that are situated in two adjacent rows of the specified cylinders.

These are best for clogged or narrow settings.

The engine, which has a small compartment, uses blocks such as high-speed cars and engines.

Parameters that Define Engine or Cylinder Blocks

There are some of the parameters that are vital for the manufacturing of engines blocks. These parameters are the most efficient requirements that make the engine block work properly.

While manufacturing, these parameters should be considered without fail as these are interlinked to each other. After fulfilling each of them only, we can delve into the successive ones:

Functional requirements

As we know that engine blocks are among the critical components of an engine, they must be equipped with all the functional requirements.

The lag in any of the requirements can deteriorate the whole construction.

- In these functional requirements, maintenance and service, the life of the vehicle, withstanding capability against pressure generated due to combustion process, housing for moving fluids and parts are on the top list.

- After getting ahold of these requirements, we can move to the material properties.

Material Properties

Along with the above functional requirements, the engineering materials should possess properties that act as driving factors.

The engineering materials used to manufacture should have high abrasion resistance, corrosion resistance, strength, modulus of elasticity.

- In these, the High strength is prominent for diesel engines due to the high compression ratio.

- Apart from these, the materials should have the low thermal expansion, density, and thermal conductivity.

- Lower thermal conductivity prevents the engine blocks from failure under optimally high temperatures, while low thermal expansion resists the engine block material to expand under higher operating temperatures.

- In addition to these, the materials should be of good machinability capability as these are the important parameters that help in machining the product efficiently.

- The manufacturing cost also keeps a prominent place while manufacturing engine blocks; it is recommended to use materials with maximum machinability.

- Damping vibration is also an effective factor in the materials used for manufacturing as there are numerous moving parts available in the engine block.

Metals Used in the manufacturing of engine blocks

Getting an idea about the functional and material properties of the engine blocks leads us towards the metals used for manufacturing cylinder blocks.

- The metals used for the manufacturing should heave some core properties that make them easier to the machine.

- The popular metals used for the manufacturing of engine blocks are aluminum alloys and cast iron.

- Cast iron alloys are used to manufacture engine blocks due to their amalgamated properties such as low cost, availability, and excellent mechanical properties.

- Some of the aluminum alloys are equipped with iron alloys, making them more efficient and help the manufacturers choose them without any doubt.

- These are quite popular for the manufacturing of cylinder blocks in a diesel engine.

- Gradually the popularity of lightweight components is increasing, for which the magnesium alloys hold the prominent place as it is super light and provides the much-needed strength to the engine blocks.

Materials and Properties of Alloys for Manufacturing Engine blocks

As we know, the engine cylinder blocks are subjected to optimal thermal strains, massive fatigue stresses, and optimal wear conditions.

These are the states that should be endured by any of the alloys which are being used for the manufacturing of engine blocks.

- It is quite important to select appropriate material that meets the most effective mechanical properties requirements.

- For instance, the ultimate tensile strength needed to manufacture an aluminum engine block is 250MPa, Fatigue strength of 60MPa, and Yield stress of 220MPa.

- These are the effective need for the alloys to be equipped with. Apart from these, numerous alloys can be used for manufacturing the engine blocks, and here we are discussing the core mechanical properties of some prominent ones.

The manufacturing of engines blocks is mainly attained with different kinds of alloys. These alloys are equipped with numerous properties that make them suitable for fulfilling all the criteria.

In these, the properties that remain at the top are the mechanical properties.

Here we will discuss those properties and why they are quite suitable for use as the core materials for the manufacturing of Engine blocks.

Gray Cast Iron Alloys

This is among the most prominent kind of alloy widely used to manufacture powered engine blocks. The Gray cast iron alloy is losing popularity due to its extensive use in manufacturing blocks.

There is a need for materials that withstand higher internal stresses, Gray cast iron alloys are abundant.

Composition

- The composition of Gray cast iron alloys are 0.2-1.0 wt.% manganese, 0.02-0.25 wt.% sulfur, 0.02-1.0 wt.% phosphorus, 2.5-4 wt.% carbon and 1-3 wt.% silicon.

Properties

- These materials provide this alloy an excellent temperature resistance, optimal wear, and damping capacity.

- These properties help it to be optimally machinable and also cost-effective.

- These are comparatively weak, and the probability of deformation and fracture is quite high.

- Due to this weakness of the Gray Cast-iron alloy, other alloys are making their path for manufacturing engine blocks such as compacted graphite iron.

- Compacted graphite iron is used for producing diesel engine blocks.

Applications

- Gray Cast Iron is widely used in the automotive sector.

- One of the effective usages is for the manufacturing of engine block for BMW M54.

- It increases the performance level of the car.

Compacted Graphite Cast Iron

Compacted Graphite Cast Iron is an alloy that consists of useful properties for different kinds of engineering applications.

These are pretty popular for usage in various engineering applications as the tensile strength and elasticity are pretty high for this alloy.

Composition

The core morphology of this alloy contains 0 to 4% of CGI alloy in which Magnesium, silicon, calcium, and iron are present makes it quite effective.

Properties

- It has excellent damping capacity, thermal conductivity and is lightweight. However, it is quite challenging to machine this alloy.

- With the help of the rotary insert tool, the applications of CGI are attaining their popularity. It helps in the machining of the alloy.

Applications

- Compacted Graphite Cast Iron is the alloy that is used in the manufacturing of engine blocks for heavy vehicles such as trucks, tractors, cars, and also for marine diesel engines.

- It has gained massive popularity in the automobile field as it helps the cylindrical blocks be highly performance-oriented.

- The reduction in weight makes it quite apt for usage.

- It was also used in bulk for the manufacturing of engine blocks for Peugeot and Ford.

Aluminum Alloys

Aluminum alloys have been the most popular alloys for a long time for the manufacturing of engine blocks. It is because this material helps in reducing the overall weight of the automobile.

With the use of aluminum alloy, one can easily attain improved performance to weight ratio and optimal fuel efficiency. Mainly there are two kinds of aluminum alloys used for the manufacturing of engine blocks. A356 and 319. Both of them have different morphology.

Properties

- The lightweight construction is amongst the best property as massive numbers of the automotive industry look for light materials to manufacture their engine core component, i.e., Engine block.

- However, there are some limitations, such as the high cost of using aluminum makes it comparatively less popular than cast iron alloys.

- The strength to weight ratio is among the foremost property that makes it exceptionally adaptable.

- Proper heat treatment of these alloys makes them equipped with high rigidity as well as optimal strength.

Composition

- Aluminum alloys have a composition of 6.5-7.5 wt.% silicon, , 0.25-0.45 wt.% magnesium, 91.1-93.3 wt.% aluminum, 0.2 wt.% copper, 0.2 wt.% titanium, 0.2 wt.% iron, and 0.1 wt.% zinc.

- This composition provides higher strength to the manufacturing.

- The modulus of elasticity is also high, which is among the core need for the manufacturing of engine blocks.

Applications

- The aluminum alloys manufacture the cylinder blocks with a combined need for lightweight and redundant material.

- This helps in providing the much-needed safety to the components available inside the engine blocks.

Engine Block Defects, Reasons, Countermeasures for Materials Used

Numerous materials are being used for the manufacturing of engine blocks. These materials can attain different defects, which can be pretty harmful to the engine blocks.

However, it is essential to be aware of the reasons as well as the countermeasures. In this part, we will provide the probable defects and the reasons for the same.

In addition to that, we will also analyze some of the countermeasures that help in reducing the probability of these defects.

Engine Block Defects

- The reduction in tensile strength of the materials used for the manufacturing of the engine blocks. With the proper test, it is prescribed that the tensile strength of the materials should be more than 250MPa.

- The hardness of the materials steeps low. The hardness of the materials used should lie above 200hb, while the difference between the sections of the casting material should lie below 30hb.

- While casting the engine blocks, the pearlite content holds an important place as it occupies more than 85% of the body.

As we know that the innovative conditions have made the manufacturing processes quite effective, but numerous production modern methods need proper transformation skills. The main reason for the materials defect is not meeting the above requirements, which results in the wear of the engine blocks.

Reasons for Engine Block Defects

The probable reasons for the above defects are as follows:

- If the alloys used in manufacturing engine blocks contain iron, then the material’s melting temperature remains at a low point. It results in the poor strengthening effect of the engine blocks.

- For those materials with poor grade quality, the above defect also causes the high content of non-metallic inclusion and trace elements.

- Improper selection procedure for the alloy elements, adding materials in the alloy, or any method change can also cause the above defects.

- The improper parametric mixture can be a probable reason for the above defects. This improper measure contains defects in composition, morphology, quantity, method, and form.

- The untimely addition of different materials in the furnace can also cause the above defects. The adjustment in the processes if takes a long time, then the element changes the composition and properties quickly, resulting in the accuracy of the material.

The above reasons can be minimized with the help of some countermeasures. These countermeasures are pretty critical and should be considered adequate for the reduction of the above defects:

Measures to Reduce Engine Block Defects

The efficient measures to reduce the probability of defects:

- It is recommended to check the materials which are used for the manufacturing of engine blocks. It includes advancement in the melting temperature, supercooling tendency, stability in the molten phase, elimination of gangues in the raw material. Maintaining the initial pouring temperature and attaining the final pouring temperature is mandatory.

- While selecting the materials, it is crucial to control the furnace condition. The stability in the furnace is vital as the insulation of the furnaces helps reduce the fluctuation in the morphology of alloys. This can easily reduce the desired time for settling up of composition. This helps in the reduction of white mouth and shrinkage probability of molten iron.

- An electric furnace used for melting is prescribed to use a carburize equipped with a high absorption rate. It is also recommended to ensure that full absorption and electromagnetic stirring should be attained as in the absence of these, the content of the whole melt decreases the amount of carbon needed.

- Reduction if fluctuation can also help to mitigate the above defects. It can be done by improving the accuracy of the composition of the alloy or other materials.

- When it comes to the intricate shape of the cylinder blocks, high strength quotient, and thin wall, it is prescribed to make sure that the molten iron used for the head casting of the engine block should have good casting performance and optimal strength. This is the prominent reason for which the morphology of the materials is equipped with high strength concentration. Low alloying measures are the best countermeasure that helps in attaining optimal casting performance and also mechanical efficiency.

Within an internal combustion engine, an engine block contains the cylinders, as well as other components. Early automotive engines had nothing but a cylinder block attached to a separate crankcase.

The crankcase and cylinder block are typically integrated into modern engine blocks. In addition to coolant passages and oil galleries, engine blocks often include other elements.

Common Problem of Engine Block

External Engine Coolant Leak

There is a puddle of water or antifreeze under the engine. Sometimes it’s the engine block itself, but it can also be a leak from a water pump, radiator, heater core, or a loose hose. It is possible for the block to crack and leak, or the freeze-out plug to become loose or rust out. Cracks usually occur in freeze-out plugs, but they are easy to replace.

Cracked Cylinder

Over time, the smooth machined walls of the cylinders will wear until the piston rings cannot seal against them anymore. A motor may require a rebuild on rare occasions if a crack develops in the cylinder wall. In extreme cases, worn cylinders can be bored larger to accommodate oversized pistons. Iron sleeves can also be inserted to restore cylinder walls to their original state.

Porous Engine Block

Often voids in castings are not a problem at all for decades since contaminants get into them during the manufacturing process. The areas where imperfections are can eventually leak oil or coolant from the poorly cast block. Because a porous engine block has been faulty since it was molded, there is nothing you can do to fix it. The manufacturer should replace any engine if there are leaks from a porous block, but they should be minor and should appear within the warranty period.

Some Key Signs of Engine Problem

Improper Lubrication

Your engine can suffer severe damage if it’s moving parts are not properly lubricated, including pistons, rings, bearings, bushes, shafts, and gears. Pistons and shaft bearings are kept cool by lubrication. By containing a detergent additive, oil cleans the inside of the engine and carries the abrasive and carbon to the filter. Lack of proper servicing can block oil pickups, causing your engine to lack oil.

Detonation

An engine detonates when it produces excessive heat and pressure inside its combustion chambers due to abnormal combustion. When ignition timing is too advanced or fuel has a low octane rating, a knocking noise is produced, commonly referred to as pinging.

When two flame fronts collide in the combustion chamber because of the advanced ignition timing or higher compression ratio than is appropriate for the fuel’s octane rating, the sound of pinging is created. In addition to increasing combustion temperature, detonation causes piston and ring land damage.

Overheating

Engines that overheat can fail catastrophically, requiring complete reconditioning or major repairs. The cause of overheating is usually coolant loss caused by defective radiators, thermostats, hoses, water pumps, or cooling fans. Regularly inspecting, servicing, or replacing these items is important.

Signs of Engine Block Failure

A wide range of engine problems, including problems with the big end, the block, the camshaft, the crankshaft, the bearings, the pistons, the head gasket, and the piston rings, can be diagnosed and repaired. In order to diagnose the type of engine failure you are experiencing, please select the one that corresponds to your specific problem.

- The lobes of the camshaft are worn out.

- Broken or cracked crankshafts.

- Head gaskets that have blown out.

- Exhaust valves that are burned out.

- The cylinder block is worn and cracked.

- Piston rings that are worn out or broken.

- Pistons with holes or cracks.

- Con-rods are bent or broken.

- Noisy, worn Con-rod bearings at the Big End.

- The main bearings are worn and the oil pressure is low.

In what way does it cost to have an engine block repaired at a garage?

You will have to spend at least $1,500 in parts and machining to repair an engine block crack. You can expect engine block repairs to take 12 to 35 hours, depending on the car you drive. Compared to compact cars and more common models, diesel and truck engines are more expensive. A fractured engine block will cost approximately $3,500 if 20 hours of labor are assumed at $100 per hour.

There is a possibility that it will be much more. Your choice of whether to repair or sell your car depends on broken engine block repair prices. Engine blocks can be more expensive to replace in the garage than replacing at your home.

Frequently Asked Questions on Engine Block

What does engine block mean?

All major components that make up the bottom end of motors are housed in the engine block, also known as the cylinder block. Fuel combustion causes the crankshaft to turn and pistons to travel up and down in the cylinder bores, which turns the crankshaft. Some engines have camshafts attached to the crankshaft.

How much does an engine block cost?

The cost of buying an engine block varies depending on the model of your car, but may range from $1,000 to $4,000. Occasionally, replacing your engine block may be cheaper than repairing your current one. If you want to weigh your options, you can talk to a mechanic for an estimate. Additionally, as you drive an older vehicle, your car’s repair cost may exceed its value, resulting in a more cost-effective alternative to drive an old vehicle.

What does the engine block consist of?

Cylinder Liner

Among the features of a wet liner cylinder block is that its walls may be removed, and they fit in the block using special gaskets. Wet liners are that type of liner that is in direct contact with the engine’s coolant. That is, the liner is entirely of one piece, rather than merely a sleeve.

Cylinder Block

Cylinder blocks are structures that contain the cylinder and related components, such as cylinder sleeves and coolant passages. During the early development of internal combustion engines, cylinders were often cast individually. Cylinder blocks were often made separately for each cylinder.

Cylinder

There are spaces around pistons where they travel. There are large holes forming a seal alongside the piston and are of precise shape. Considering the size and number of cylinders of an engine, we can determine its power and size.

Crankshaft

This component is found at the bottom of modern engine blocks, where the crankshaft is housed. There are other components, such as engine mounts, core plugs, coolant, and other mountings and ancillary components.

Deck

There is a cylinder head on the top surface of the block.

Oil Passage

Combined with cylinder heads and crankshafts, these allow oil to be transported to them.

What are types of Engine Block?

Inline Engine, V Engine, Boxer engine are the types of Engine

What causes engine block burst?

A large portion of the year is hot in regions where engines can easily overheat. A leaky head gasket or warped cylinder head can be caused by overheating at first. As the overheating worsens, the rapidly expanding metal damages the cylinder head externally or internally.

Cold-weather or cold-climate scenarios can cause an engine’s block to freeze. There isn’t enough strength in the coolant. In an engine, cooling fluid expands as it freezes. In the event of a freeze, the coolant presses against the metal around it, shattering the block and leaking antifreeze and causing the cooling system to fail. You’re either forced to repair your cylinder head or sell your car if this happens.

How an engine block does looks like?

A solid piece of metal is what makes up your engine block, usually made of aluminum or high-quality iron. Inside the engine block, cylinders are perfectly smooth and round, allowing pistons to travel up and down with minimal friction. At the bottom of the oil pan is your crankshaft, which rotates as a result of the downward force exerted by your pistons. All that moving metal generates a lot of heat, which is why a water jacket is cast into the engine block.

Can an engine block be replaced?

The engine block of a crack can be repaired, but is usually a good candidate for replacement, whether it is with a rebuilt engine, a new engine, or a salvaged engine. Excess heat, typically caused by a coolant issue, can cause a cracked engine block, but there are a number of other causes.

Is it cheaper to replace or rebuild the engine?

In comparison to engine replacement, engine rebuilding may save you money depending on the problem you have and the cost of the parts. Your engine can be rebuilt for up to half the cost of replacing it, depending on the circumstances

Can you fix an engine block?

The first step in restoring the engine is to strip it of all its components. It is necessary to disassemble and remove every component of the block. The engine’s integrity and reparability must be verified by pressure testing after it’s stripped to the bare block. A machinist may weld or insert repair plugs into the crack in some cases.

Replacement of blocks is more common but the assembling process remains difficult, even if you are lucky enough to have your engine block repaired. Repair costs are often high & routine service components and fluids, new bearings, seals, and gaskets will be required. Additional dry rotted or damaged components can be checked during the disassembly process. The cylinder head should also be inspected for damage. There will be a separate project if it needs to be replaced or repaired.

Which engine block is the best?

Cast iron is the best material for engine blocks. There is no doubt that the Ford Coyote is a great option for drag racers today. In comparison to aluminum engine blocks, it is more durable, cheaper, and has a higher power rating. There are several disadvantages to this product, including the rust, the added weight, and the inability to repair it.

What are the 3 parts of cylinder block?

Three stationary parts of an automobile engine comprise the cylinder block, cylinder head, and crankcase.

Is engine block same as cylinder block?

Crankcase and cylinder block make up the engine block. There are two types of engine blocks: one-piece and two-piece. On air-cooled engines, the cylinder block is composed of the cylinder bore, cooling fins, and valve train components.

What is a cylinder block in an Engine?

Cylinder blocks are structures that contain cylinders, cylinder sleeves, and cooling passages. A cylinder block for each cylinder was usually cast individually in the early decades of internal combustion engine development.

What is the top of the engine block called?

The top of the engine block is known as deck.

How do you fix crack engine block?

Cracks in engine blocks can occur for a variety of reasons, but the majority is caused by excessive heat, which is usually caused by a coolant issue. Overheated areas on the engine expand, while cooler areas remain unchanged. Due to this, the engine block is stressed, causing a crack to form.

In addition to creating engine cracks, a water pump can prevent coolant from flowing through the system properly, resulting in severe overheating. However, casting failures during injection molding can result in a thinner engine block in some places. Heat can cause thin cracks to form.

High Rated Automotive Engineering Course

Automotive 101: A Beginners Guide To Automotive Repair

Automotive Engineering: Automobile Fundamentals and Advanced

Automotive Engineering; Hybrid Electric Vehicles

Do it Yourself – Automotive Electrical Diagnosis – Beginner

Do it Yourself-Automotive Electrical Diagnosis-Intermediate

Automotive Engineering; Common Rail Direct Injection(CRDI)

Fundamentals of Internal Combustion Engines – IC Engines

Hybrid and Electric Vehicle for Beginners FULL Course 2021

Automobile Safety: Understanding Car Crashes for beginners

Hybrid Vehicles The Fundamentals & Operating Principles

Summary

With the proper analysis of the information regarding the engine blocks, we can easily acquire all the relevant and efficient factors needed for understanding. This excerpt helps us understand the core functionality of the engine blocks and helps us get the idea of materials used for the manufacturing.

We are also equipped with the properties that make these materials quite efficient as per the properties. The parameters that define the materials are icing on the cake that helps us understand the cylinder block.

In addition to these, the probable defects in the engine blocks can easily help us get rid of the unusual problems. This excerpt provides all-around information; however, piles of information about engine blocks can be described further.

Refer to our few interesting articles,

Reference Articles