The fuel injection system is elaborated along with its basics, types of fuel injection, advantages, disadvantages, etc.

Let’s explore!

What is Fuel Injection System? Definition

Let’s try to understand the fuel injection system basics, definition, meaning, etc.

Fuel Injection Basics

When we travel by any vehicle, we need to fill the tank with oil unless is an electric vehicle. In the petrol station, the fuel tank is filled with petrol or diesel, and the car moves.

Now, this fuel is injected into the engine cylinders and combustion happens to produce power which drives the vehicles and we can move from one place to another.

There may be few things.

- The injection of fuel into the cylinders needs to be controlled to control the vehicles or cars.

- If the car moves faster, fuel injection requirements will be more.

- If the car is slow, fuel injection may be less.

- In case of the car not moving but is working, fuel injection will be minimal.

Now, if we ask,

- how does this thing work?

- how is fuel injected based on requirements?

- how to decide when to inject fuel?

- how much fuel needs to be injected?

- how do maintain an air-fuel mixture for multi-cylinder engines?

- how to maintain the proportion of air-fuel mixtures, i.e., whether a lean mixture or rich mixture is required? Like in the starting of any engine that is the cold engine, a rich mixture is required, after that lean mixture is provided. Agin during speed up, the rich mixture is required.

Here, fuel injection is introduced.

Why Do We Need Fuel Injection?

Now to maintain all these things, a separate system, that is fuel injection system is introduced in the automobile industry, which maintains the proper injection of fuel oil into the cylinder.

The main reasons for this system shall be,

- To maintain proper air-fuel mixture,

- To maintain proper air-fuel distribution,

- The efficiency of the engine is improved,

- It optimizes the fuel consumptions,

- Reduces waste of fuel

- It helps proper fuel distribution for single as well as multiple cylinder engines.

- It prevents detonation as well as knocking,

History of Fuel Injection System

Fuel injection is the most widely used process to inject fuels into automotive engines and this process.

But the diesel engine vehicles are using fuel engines for a long time.

- In the 1940s Mercedes Benz OM 138, diesel engine passenger cars were using fuel injection systems.

- In case of petrol engines, fuel injection was introduced in the 1950s.

- Later, in the 1990s the fuel injection started to replace the carburetors.

Also Read: Types of Cars

Fuel Injection vs Carburetor

The fuel injection system became popular because of its various advantages over the carburetor.

- The introduction of fuel injection systems replaced the use of carburetors in automobile vehicles.

- The fuel injection system is available in every diesel engine vehicle but also in some spark-ignition engines.

There is a major difference between fuel injection and carburetor.

Let’s see the difference between fuel injection vs carburetor,

Fuel Injection vs Carburetor

| Fuel Injection | Carburetor |

| The fuel injection atomizes the fuel and gets through a small nozzle. | While the carburetor depends on suction created through the venturi tube to get the fuel into the airstream. |

| Fuel injection is applicable for petrol and diesel engines both. | Carburetor cannot be used in diesel engine. |

| Widely use | Use is limited nowadays |

| It can control the air-fuel ratio and increase the performance | A carburetor cannot control the correct air-fuel ratio and may face problems if fuel temperature or air pressure is changed. |

| Maintenance and cleaning of fuel injection is not easy, required skilled personal. | Maintenance and cleaning of carburetor is easy |

| It is expensive | Not expensive |

We have got a basic idea of which one to choose between fuel injection vs carburetor.

Now, the fuel injection system is also developed, and there are some differences between conventional and modern injection system.

Also read: Types of bikes

Difference Between Traditional & Modern Fuel Injection System

| Traditional Fuel Injection system | The modern Fuel Injection system |

| In case of traditional system, fuel oil may have liquid droplets when it passes through the intake manifold. | No droplet forms. |

| Due to droplet formation, the mixture will not be proportionate | Proportional mixture is produced |

| Efficiency can be slightly less | Maximum efficiency |

XPH is your home for BMW, Audi, Ford Mustang, VW, Porsche and Nissan GTR aftermarket parts.

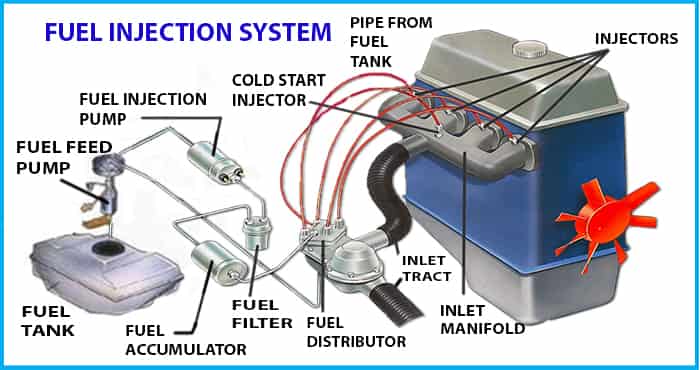

Parts of Fuel Injection System

Before going to understand the working principle or types of fuel injection system, let’s check the various parts of components used in this system.

As this system controls the mixture, atomize and properly distribute into the cylinder, there are minimum below components,

- Fuel tank

- Pumping system

- Fuel injector

- Fuel oil filter

- Metering device & control

- Mixture control device

- Distributing system

- Timing control

Let’s learn the basic function of all these parts for better understanding.

Explore accessories for your Jeep

Fuel tank

There will be a fuel tank in which fuel is stored and it is supplied by a pumping system.

Pumping system

- A pumping system means it works the same as a pump, that is, to transfer liquid from one place to another.

- Here, fuel needs to be transferred from the fuel tank to the engine cylinder, and the pumping system is used to do this work.

- There are two types of pumps used in this pumping system, one is the fuel feed pump and another injection pump.

- The fuel feed pump transfers fuel from the fuel tank to fuel high-pressure pump i.e., the fuel injection pump.

- On the other hand, a fuel injection pump delivers high-pressure fuel to the fuel injector. It normally maintains pressure around 100 bar -220 bar.

Fuel Injector

The fuel injector is the main part of this injection system and fuel injection is done with the help of it.

A fuel injector is consisting of the following parts,

- Body

- Nozzle

- Spring

- Needle valve

A fuel injector helps the injection system as follows,

- Automize the fuel,

- Make fuel into very fine liquid droplets,

- It helps to increase the surface area of fuel and ease of combustion,

In case of a compression-ignition engine, a governor is used to control the fuel flow based on requirements.

These governors can be,

- Mechanical type

- Pneumatic type

Fuel oil filter

- It helps to remove all impurities from the fuel oil and increase the efficiency of combustion as well as engine efficiency.

Metering device & Control

- We have already learned that the requirement of fuel depends on whether it is a cold start or engine is normal running or low speed or high speed etc. many factors. Hence, this flow should be measured to make proper proportion.

- A metering element is there to measure the flow and one metering control element to adjust the flow.

Mixture control device

- The ratio of the air-fuel mixture is controlled by a mixture control device based on the system demands.

Distributing system

- Now, the mixture of the air-fuel needs to be supplied to the cylinders equally by the distribution system.

Timing control

- It helps to fix the timing control for start-stop.

Spring is here! Save big on our best-selling WAGNER TUNING BMW F CHASSIS N55 CATTED DOWNPIPE

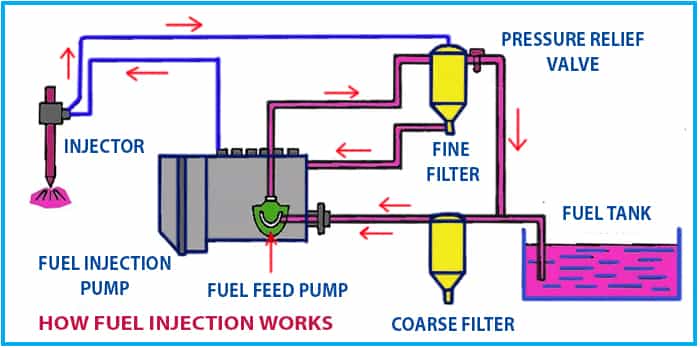

How Does Fuel Injection Work? Working Process

The working process shall be as follows,

- Fuel is stored in the fuel tank,

- The fuel feed pump sucks the fuel from the fuel tank and transfers it to the fuel injection or high-pressure pump,

- Fuel injection pump build up high pressure,

- The needle valve in the fuel injector is open under pressure, without pressure it is closed,

- Due to the pressure build-up in the fuel oil, the needle valve will be opened,

- Once the needle valve is opened, the pressurized fuel will be sprayed to the inlet manifold or the engine cylinder,

- Fuel is sprayed at the nozzle outlet and forms fine liquid droplets,

- Combustion happens in the cylinder with these fine droplets in presence of air.

Types of Fuel Injection System

The fuel injection systems are widely classified and they have different types.

- Primarily, there are two types internal mixture formation and external mixture formation.

- The internal mixture formation systems are further classified into two types namely, direct injection and indirect injection systems.

- External mixture formation is also classified into two types namely, single point and multi-point injection systems.

- In these types, there are various other types but these are the basic classifications of the fuel injection systems in automobile vehicles.

Let’s see each type one by one.

Also Read: What is Governer

External Mixture Formation Fuel Injection

The external mixture formation is also known as manifold injection systems. They are used in Otto engines (petrol engines).

- In this system, the fuel is injected into the intake manifold and it starts to form the air-fuel mixture.

- When the intake valve opens the mixture is sucked into the intake manifold.

- The rate or timing of the fuel is controlled either mechanically or by using the electronic control unit.

There are two types of manifold injection systems, let’s see it one by one.

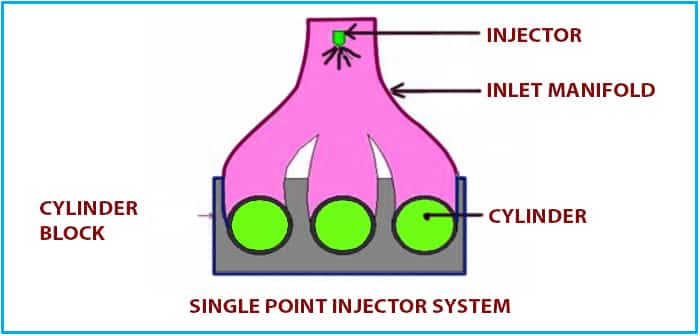

Single Point Fuel Injection Systems

The name itself suggests the construction of the injector, it has the single fuel injector.

- This injector is placed behind the throttle valve.

- Single point injection systems are somewhat close to carburetted systems.

- A single point injection system is a type of electronic fuel injection system that uses a single injector or pair of injectors mounted in a centrally located throttle body.

- If there is no metering jets or fuel bowl float, this throttle system resembles a simple carburetor.

- Fuel is sprayed directly into the throttle bore by the fuel injector.

There are various sensors used in this system let’s know them in brief.

Inductive pickup sensor

- The inductive pickup sensor helps the ECU by giving out information about the crack shaft speed and the engine speed.

- The ECU processes this information and calculates the injection time accordingly.

Lambda probe

- This is the oxygen level measuring sensor.

- The lambda probe will measure the level of oxygen in the air-fuel mixture and sends the information to ECU.

- ECU will regulate the air supply accordingly so that the fuel can be burnt efficiently.

Air temperature sensor

- The air temperature sensor as the name suggests shows the temperature of the cooling water system and the intake system.

- The air temperature sensor helps to get the correct density of air required, whereas the cooling water sensor shows the engine is cold or not.

- So accordingly, the ECU will be injecting fuel to start vehicles in cold weather.

Throttle potentiometer

- It is located on a butterfly spindle and most modern vehicles are using this sensor.

- It indicates the exact amount of throttle opening to the ECU.

Also Read: What is Engine

Advantages of single point injection system

- The system pressure in not dependant on the intake pressure as compared to carburettors.

- Reduced fuel consumption

- Improved performance through greater latitude of the intake tract.

- The large distance of heat-stressed parts leads to fewer steam bubbles and a cheaper delivery pump.

Disadvantages of the single-point injection system

- Only one fuel injector is available for all cylinders.

- Fuel may not reach to all cylinders if not optimized correctly.

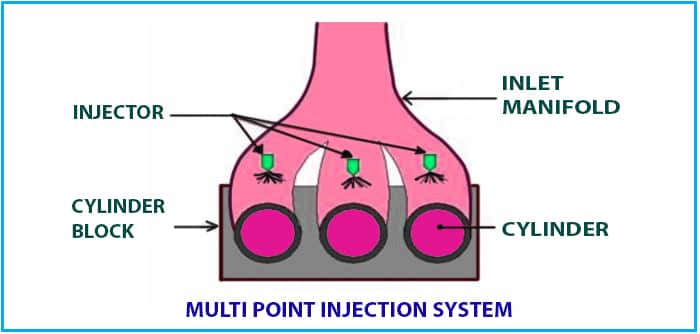

Multi-point Fuel Injection Systems (MPFI)

The single-point injection systems are not as popular as multi-point fuel injection systems nowadays.

There is a simple difference between the single point and multi-point fuel injection systems.

- In multi-point fuel injection, there are injectors for each cylinder.

- If suppose an engine is a four-cylinder engine then there will four injectors placed on each cylinder.

- There are three types of multi-point fuel injection systems. The lag problem was present in the single cylinder.

- The lag occurs when the fuel is injected into the admission valve and the driver suddenly changes the motion or stops the vehicle.

- The fuel amount can be changed only in the next admission of fuel.

So, the fuel could be wasted. So, to eliminate the lag problem sequential MPFI system was created.

The types of MPFI are sequential fuel injection, simultaneous fuel injection, and batched fuel injection system.

Components of Multi-point Fuel Injection System

- Mechanical solenoid injector – To inject the fuel to get into the intake manifold.

- The electronic control unit (ECU) – It controls all the operations based on the received information from the sensors.

- Sensors like temperature sensors, speed sensors, throttle position sensors, airflow meters measure their desired work and send information to ECU.

- Air filter for removing the particles from the air.

Working of MPFI systems

- Firstly, in the MPFI system the fuel pump is used to provide the fuel to the engine manifold.

- The ECU controls every fuel injector provided on each cylinder.

- The sensors send the signal to the ECU about the amount of mixture needed for the engine. The fuel injectors inject the fuel accordingly.

- ECU controls how much fuel is to be supplied for each cylinder and the same amount of fuel is sprayed equally in each cylinder to get good combustion efficiency.

Advantages of multi-point fuel injection systems

- Increases fuel efficiency and durability of the engine.

- Each cylinder is supplied with a precise amount of air-fuel mixtures

.

. - Engine cranking is not necessary for cold weather.

- MPFI system gives better fuel economy and less exhaust emissions.

- Better acceleration and deacceleration of the engine also reduces the difference of power developed in each cylinder.

- Volumetric efficiency is high.

Disadvantages of multi-point fuel injection systems

- The system is complex and requires more space.

- Regular inspection of fuel injectors is necessary.

- It’s a complex system so it is costly compared to conventional systems.

- Repairing is not easy.

Indirect Fuel Injection System

The indirect injection system is the part of internal mixture formation category.

- In the indirect injection system, the fuel is not in direct contact or it is not directly injected into the intake valve.

- The direct injection systems are favored more but manufacturers like Volkswagen, Toyota, Ford use the dual injection systems.

- The indirect injection systems spray the fuel on intake valves whereas direct one’s spray into the combustion chamber.

- Due to complexity, indirect fuel injection systems are used in higher-end costly models.

- Also, indirect injection allows better air-fuel mixing.

These systems are also known as port injection systems, as they spray fuel on the back of the intake port.

Types of indirect combustion chambers

Swirl chamber

The swirl chamber is having a spherical shaped chamber placed in the cylinder head and separated from the engine cylinder with the tangential throat.

- At the time of compression stroke, it allows about 50% of the air in the swirl chamber that produces a swirl.

- Now after the combustion products return through the same throat to the main cylinder.

- This causes more heat loss to the walls of the passage.

- This type of chamber is mostly used when the fuel control and engine stability are more preferred or important than the fuel economy.

Pre-combustion chamber

This one is located at the cylinder head with connection to the engine cylinder via small holes.

- The pre-combustion chamber gets 40% of the total cylinder volume.

- At the time of compression stroke, the air is taken from the main cylinder and fuel is injected, thus the combustion starts in the pre-combustion chamber.

- The more combustion takes place in the main cylinder.

- A pre-combustion chamber is useful for the multi-fuel capability.

Air-cell chamber

This one is cylindrical in shape and with a hole at the end. It is mounted where the axis is parallel to the piston crown.

- The air cell basically mounted to minimize the thermal contact with the mass of the head.

- At the time when the injector fires up the small jet of fuel enter the air cell and it ignites.

- The air cell is a kind of compromise between indirect and direct injection systems.

- It has efficiency advantages like direct injection systems and simplicity, ease like indirect injection systems.

Advantages of indirect combustion chambers

- The injector is available cheap.

- Indirect injection is simpler to design and manufacture.

- Higher engine speeds can be achieved when the combustion is continuing in the pre-chamber.

- Alternative fuels like biodiesel, vegetable oils can be used without any clogging problems.

- Indirect injection systems have less stress production on internal components. So, it is possible to make a common platform for petrol and diesel engine for cost-saving.

Disadvantages of indirect combustion chambers

- Lower fuel efficiency as compared to direct injection systems.

- For a cold start in diesel engines glow plugs are needed.

- Not suitable for high-specific power outputs engines like turbocharged engines.

- Because of applying pressure at only a specific point on the piston, the piston crown may get damaged.

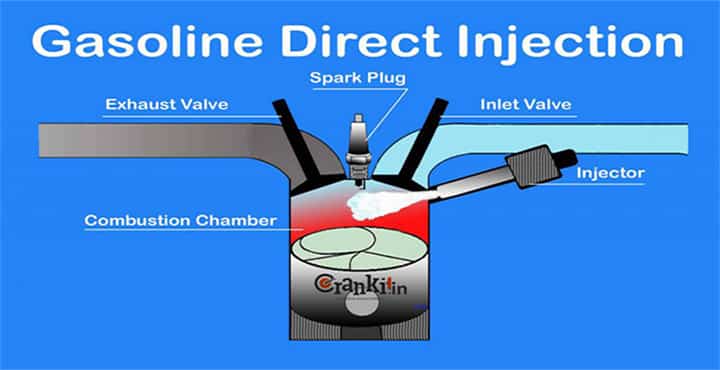

Gasoline direct injection system

The gasoline direct engine injection system is also known as petrol direct injection system.

- It is used for petrol engines.

- There is a simple difference between the gasoline direct injection (GDI) and indirect injection systems.

- In GDI, the fuel is directly injected into the intake manifold.

- It can be useful for increasing engine efficiency, specific power output, and exhaust emissions.

The systems like common rail system in which long metal cylinder is used to distribute the fuel under extremely high pressure. Distributor and inline pump system is used to push the pressurized fuel to the injectors.

Also, unit direct system in which injectors are made as single unit positioning over each cylinder.

In case of the direct injection systems, the ECU has to think and act more quickly for feeding the fuel into cylinders. It will help in achieving performance and fuel efficiency.

Advantages of gasoline direct injection systems

- Gasoline direct injection systems react more quickly for the changes in timings, fuel additions.

- The vehicle is able to act quickly on the basis of inputs from the sensors.

- Aggressive ignition timing curves and no throttling issues.

- The engine will get precise control of fuel and injection timings.

- The fuel burns where it is needed without spending time on intake valves.

Disadvantages of gasoline direct injection systems

- Costly repairs and expensive installations.

- Deposits on the intake ports and valves.

- Due to the shorter time for fuel injection, the capability to produce the highest power is limited at high RPM.

- Increased carbon deposits due to lack of cleaning.

Methods of Fuel Injection

There are mainly two basic methods are used for injection system in compression Ignition engines.

- Air Injection Method

- Solid Injection Method

Now, let’s try to understand both these process,

Air Injection Method

In CI engine, air is compressed in the compression stroke and its pressure and temperature is increased.

After this stroke, fuel is injected by the fuel injector into the cylinder.

- Air injection means, as the name suggests, fuel injection in the compressed air.

- This compression system is required only to compress the air and make ready for combustion with fuel injection.

- This additional compression system increases the weight of engine.

- It reduces the output of brake power, due to higher engine size.

- Fuel with high viscosity can be easily used.

Solid Injection Method

In this method, as the name suggests, fuel is not injected or compressed, rather it is injected into the cylinder directly without compressed air requirements.

High Rated Automotive Engineering Course

Automotive 101: A Beginners Guide To Automotive Repair

Automotive Engineering: Automobile Fundamentals and Advanced

Automotive Engineering; Hybrid Electric Vehicles

Do it Yourself – Automotive Electrical Diagnosis – Beginner

Do it Yourself-Automotive Electrical Diagnosis-Intermediate

Automotive Engineering; Common Rail Direct Injection(CRDI)

Fundamentals of Internal Combustion Engines – IC Engines

Hybrid and Electric Vehicle for Beginners FULL Course 2021

Automobile Safety: Understanding Car Crashes for beginners

Hybrid Vehicles The Fundamentals & Operating Principles

Conclusion

Hence, we have got a clear idea about fuel injections, its basic, types, advantages, application, etc.

Any doubts, please feel free to contact us!

Further Study

If you are interested to have certificate programs

Get started in your dream career today with 60% off registration at IAP Career College.

Our Videos

Refer YouTube

Our Apps

Check out our ‘MechStudies – The Learning App’ in iOS

& Android

Refer to our few interesting articles,